- Product Details

- {{item.text}}

Quick Details

-

Drum size:

-

D.1500*L2500mm

-

Machine Material:

-

304 stainless steel(2.5mm thickness)

-

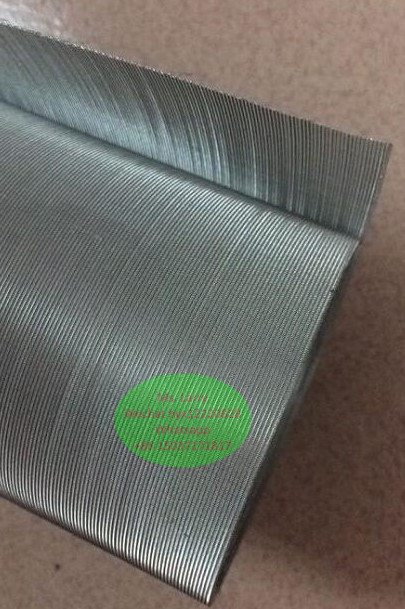

Filter Material:

-

316L stainless steel(3mm thickness)

-

Geared motor:

-

2.2kw

-

Backwashing pump:

-

1.5kw

-

Application:

-

Filtration

-

Aperture:

-

60um

-

Usage:

-

Wastewater Pre-treatment

Quick Details

-

Place of Origin:

-

Henan, China

-

Filtration accuracy:

-

80um

-

Processing capacity:

-

500m3/h

-

Drum size:

-

D.1500*L2500mm

-

Machine Material:

-

304 stainless steel(2.5mm thickness)

-

Filter Material:

-

316L stainless steel(3mm thickness)

-

Geared motor:

-

2.2kw

-

Backwashing pump:

-

1.5kw

-

Application:

-

Filtration

-

Aperture:

-

60um

-

Usage:

-

Wastewater Pre-treatment

Aquaculture Microfiltration machine/rotatry drum filter for fish farm

1. Introduction of rotatry drum filter for fish farm

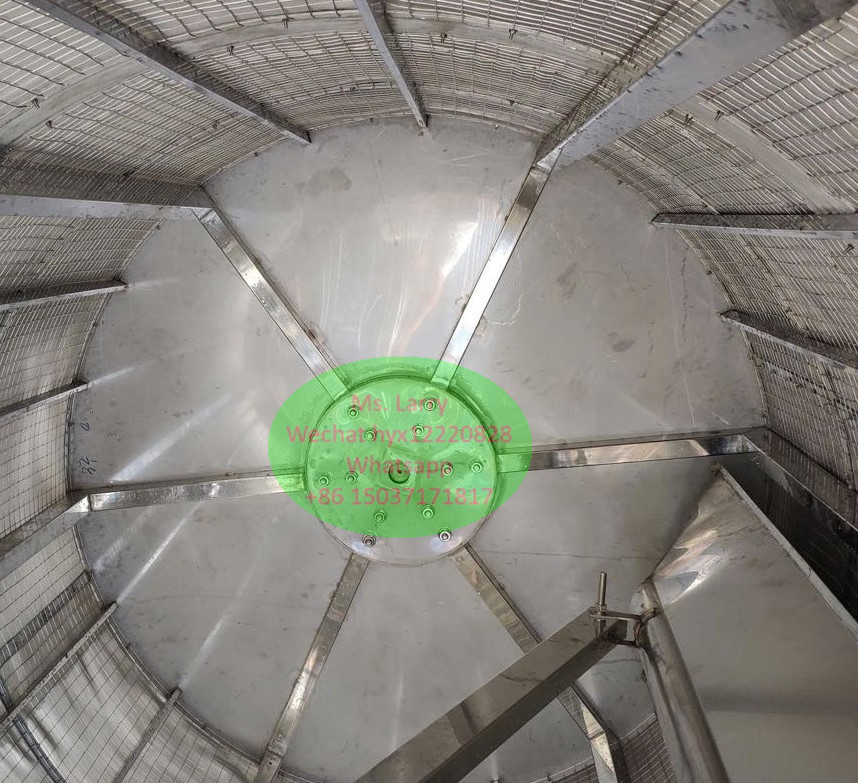

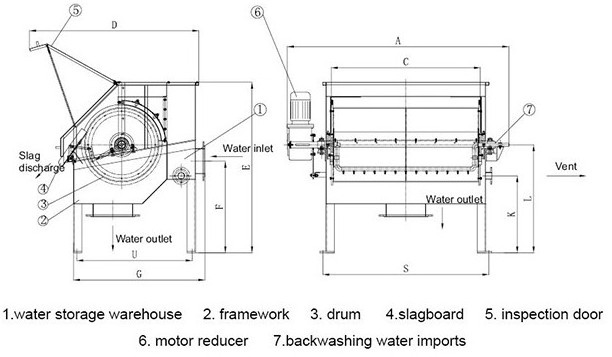

The microfiltration machine is a rotary drum type screen filtration recovery solid-liquid separation device. The working principle: the treated wastewater enters the microfiltration machine drum in the axial direction and flows out through the screen in a radial radial direction. The impurities in the water (fine suspension, fiber, pulp, etc.) are trapped in the microfiltration machine drum. Inside the upper screen. When the impurities trapped on the filter screen are brought to the upper part of the microfiltration machine by the drum, they are backflushed by the pressure flushing water and flow out in the slag discharging tank. During operation, the diameter of the micro-filter drum 2/5 is exposed to the water surface, the number of revolutions is 1-4r/min, the filtration speed of the micro-filter can be 30-120m/h, and the washing water pressure is 0.5-1.5kg/cm2. The amount of flushing water is 0.5-1.0% of the production water. When used for reservoir water treatment, the algae removal efficiency of the microfiltration machine is 40-70%, and the plankton efficiency is 97-100%. The micro filter has a small footprint and a large production capacity (250-36000m3/d). It is easy to operate and manage. The microfilter has been successfully applied to water supply and wastewater treatment.

Working principle:

After the microfiltration machine starts, the water will flow from the inside to the outside of the drum. The dirt in the water was intercepted by a stainless steel screen. After running for a period of time, the dirt intercepted by the stainless steel screen is more and more, the resistance to the water flow is getting bigger and bigger, the drum starts to rotate slowly, and at the same time, the high pressure water pump pumps the high pressure water out of the nozzle, and the high pressure water will stick. The dirt attached to the screen is washed away, and the dirt is collected by a collecting tank placed inside the drum and then discharged from the drain pipe. Complete the process of solid-liquid separation.

2. Advantage and Features of rotatry drum filter for fish farm

The microfiltration machine has the advantages of small footprint, large production capacity and operation management. It can be used for pretreatment of raw water in drinking water plants, treatment of industrial water, pretreatment and final treatment of domestic water, and useful in industrial wastewater.

Playback of matter, etc.

1.

The device removes organic and inorganic debris and various types of phytoplankton, algae or fiber pulp from the water.

When used in reservoir water treatment, the algae removal efficiency is 40-70%, except for plankton efficiency of 97%.

2.

Compared with other equipments, it has the characteristics of small floor space, easy installation, convenient operation and management, no yao agent and large production capacity (250-36000m3/d).

3.

Continuous operation, automatic flushing, no need for special care, the highest concentration of recycled fiber can reach more than 12%.

4.

The utility model has the advantages of simple structure, stable operation, convenient maintenance and long service life.

3. Technical parameter of rotatry drum filter for fish farm

| Model | Drum Size | Capacity | Pump | Motor |

| VLD-WLJ-20 | Φ400×400 | 20m 3 /h | 0.37KW | 0.55KW |

| VLD-WLJ -30 | φ500×500 | 30m 3 /h | 0.37KW | 0.55KW |

| VLD-WLJ- 40 | φ650×650 | 40m 3 /h | 0.45KW | 0.75KW |

| VLD-WLJ- 50 | φ800×800 | 50 m 3 /h | 0.37KW | 0.9KW |

| VLD-WLJ- 80 | φ800×1000 | 80 m 3 /h | 0.37KW | 1.1KW |

| VLD-WLJ- 100 | φ1000×1000 | 100 m 3 /h | 0.9KW | 1.5KW |

| VLD-WLJ- 150 | φ1500X1000 | 150m 3 /h | 1.1KW | 1.8KW |

| VLD-WLJ- 200 | φ2000X1000 | 200m 3 /h | 1.1KW | 2.6KW |

| VLD-WLJ- 250 | φ2500X1000 | 250m 3 /h | 1.3KW | 3.2KW |

4. Photos of rotatry drum filter for fish farm

5. Final Products