- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

890*920*900mm

-

Weight (T):

-

0.79 T

-

Power (kW):

-

160

-

Application:

-

Heating

-

Melting Material:

-

Iron Steel

-

Keyword:

-

Heat Treatment Electric Furnace

-

Capacity:

-

1.0T-50T

-

Function:

-

High Efficiency Drying

-

Final product:

-

Metal Liquid

-

Color:

-

Support Customzied

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

zhengan

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

890*920*900mm

-

Weight (T):

-

0.79 T

-

Power (kW):

-

160

-

Application:

-

Heating

-

Melting Material:

-

Iron Steel

-

Keyword:

-

Heat Treatment Electric Furnace

-

Capacity:

-

1.0T-50T

-

Function:

-

High Efficiency Drying

-

Final product:

-

Metal Liquid

-

Color:

-

Support Customzied

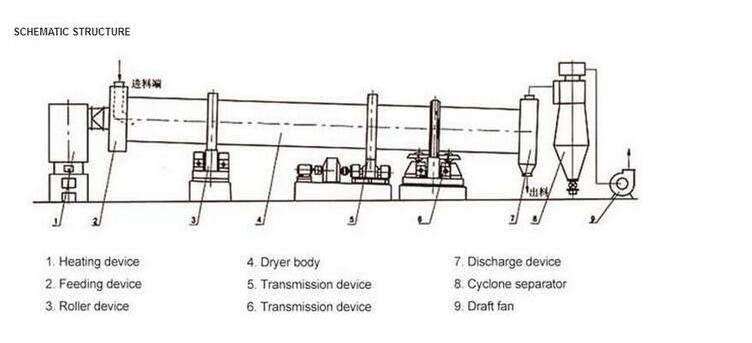

Drying Equipment HZG Series Rotary Kiln Dryer

WORKING PRINCIPLE

Rotary Drum Drier is a kind of dryer with rotating cylinder body which is a little bit incline. The wet material is loaded from one end from the screw material adding device continuously, and is stirred by the bafflers that are uniformly distributed in the barrel.

The material is uniformly distributed and dispersed in the dryer and fully contacts the hot air of counter flow. When the material passing through the cylinder inside surface, it will contact with the hot air circling inside and being dried .Most of the dried product will be discharged from the other end of the dryer. Small part of the fine granule goes into the cyclone separator with the exhaust air. The powder will be separated and collected, and the exhausted air will be ejected to the atmosphere. During the drying course, the material will slowly move to the lower end from the higher part recur to the slowness rotating of the cylinder.

APPLICATION

This dryer widely used in the following industries:

- Drying large particles and heavy material for chemical, mining, metallurgy and other industries, such as: mining, blast furnace slag, coal, metal powder, fertilizer, ammonium sulfate.

- Drying powder or granular materials which have special requirements, such as: HP vesicant, lees residue, precipitated calcium carbonate, activated clay, magnetic powder, graphite, dregs.

- Drying the material which required low-temperature and continuous drying process.

FEATURES

(1) Large throughput capacity and continuous operation

(2) Simple configuration and easy to operate

(3) Good adaptability of materials

(4) Low energy consumption

(5) Low maintenance cost

SCHEMATIC STRUCTURE

TECHNICAL PARAMETERS