- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AOLS

-

Dimension(L*W*H):

-

2800*1300*2200MM

-

Motor Power (Kw):

-

30KW

-

Power (kW):

-

30KW

-

Weight (KG):

-

500 KG

-

Name:

-

Rotating Roller pellet machine

-

Application:

-

Poultry Farm

-

Capacity:

-

80-2000KG/h

-

Usage:

-

Homemade pellet mill plan

-

raw materail:

-

Sawdust, leaves, rice Husk, wood

-

Color:

-

Clients' Requirement

-

Function:

-

pellet making

-

Humidity:

-

10-15%

-

application:

-

Make Biomass Pellets

-

countries:

-

South Africa, UK, US, Europe

Quick Details

-

Pellet Diameter (mm):

-

4 - 12

-

Output (kg/h):

-

100 - 2000 kg/h

-

Place of Origin:

-

China

-

Brand Name:

-

AOLS

-

Dimension(L*W*H):

-

2800*1300*2200MM

-

Motor Power (Kw):

-

30KW

-

Power (kW):

-

30KW

-

Weight (KG):

-

500 KG

-

Name:

-

Rotating Roller pellet machine

-

Application:

-

Poultry Farm

-

Capacity:

-

80-2000KG/h

-

Usage:

-

Homemade pellet mill plan

-

raw materail:

-

Sawdust, leaves, rice Husk, wood

-

Color:

-

Clients' Requirement

-

Function:

-

pellet making

-

Humidity:

-

10-15%

-

application:

-

Make Biomass Pellets

-

countries:

-

South Africa, UK, US, Europe

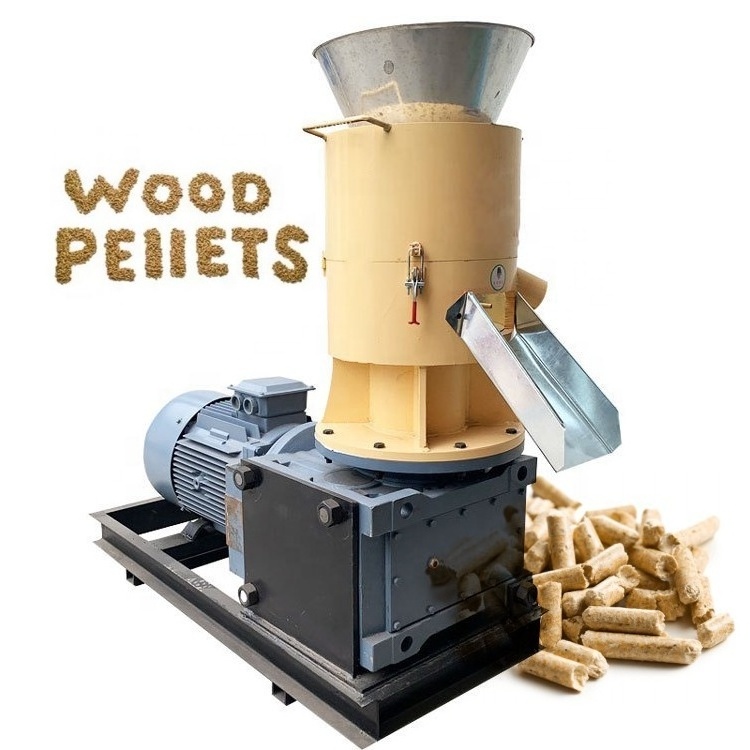

PENG MEI Wood Pellet Machine Biomass Fuel Wood Sawdust Straw Pellet Making Machine Granulator Production Line

high efficiency Rotating Roller pellet machine sawdust pellet maker feed extruder machine for farmingThis series Biomass flat die pellet machine is a new type of pellet machine, specifically aimed at biomass materials. It is widely used for pelleting various biomass materials. Transmission gears adopt high quality alloy steel, surface treatment of cemented quenching, after elaborate processing, smooth transmission, low noise, large load capacity, low temperature rise, long working life. Adding strong gluten in the bottom, high anti-pressure ability. It is suitable for home using or small enterprises producing biomass pellet fuel or feed. It can be configured to diesel or electric motor, it is mobile flexible and simple to operate.

Rotating Roller Sawdust Wood Pellet Mill Features:

(1) Adopt reduction box with low noise, long lifespan gear and can rotate forward and reverse. Other manufacturers adopt low cost bevel gear that cannot rotate reverse.

(2) The pressing die and main shaft adopt Cr12, which is more wear-resisting because of high Cr content. The special heat treatment makes their hardness to be 60HRC. Other manufacturers use 45# instead with low hardness and wear-resistance.

(3) The roller, pressing die, main shaft and roller shaft are processed by vacuum heat treatment other than carburizing and quenching (that other manufacturers use) to have higher hardness, wear-resistance and longer lifespan.

(4) The sealing of spare parts for small pellet machine is excellent. The roller shaft is sealed on both sides, while other manufacturers only seal one side.

(5) The feeding hopper applies whole sheet metal edge instead of welding to be more stable and firm.

(6) The compression ratio of small pellet press determines the quality of your pellets. We have professional team doing the raw material test and have obtained best compression ratio for over 20 kinds of common seen biomass.

(7) The electric components adopt top brands in China to guarantee stable performance.

|

Model |

Capacity (kg/h) |

Power (kw) |

Specification (mm) |

Weight (t) |

Dimension (mm) |

|

KLR-250 |

100-200 |

15 |

4-6 |

0.5 |

1400*600*1000 |

|

KLR-280 |

150-250 |

22 |

4-6 |

0.65 |

1760*670*1600 |

|

KLR-300 |

100-300 |

30 |

4-8 |

0.76 |

1860*670*1600 |

|

KLR-350 |

300-600 |

37 |

4.5-10 |

2.2 |

1900*850*1750 |

|

KLR-450 |

500-800 |

55 |

4.5-10 |

4.3 |

2300*1100*1900 |

|

KLR-550 |

1000-1500 |

90 |

4.5-12 |

5.5 |

2350*1100*2050 |

|

KLR-800 |

1500-2500 |

160 |

4.5-12 |

6.8 |

3200*1235*2700 |

|

KLR-1200 |

3000-5000 |

320 |

4.5-15 |

19 |

3800*1700*4200 |

The Development Prospect Of The Wood Pellets Production

How to make your own pellet with our feed granulator? The complete feed pellet production line is composed the following steps.

Step1: Crushing Process

Crusher is used to crush the raw materials to suitable size before pelletizing.

Step2: Mixing Process

Mixer is used to mix different raw materials. Our mixer is specially designed for discharge mechanism and large open Angle, so it has the advantage of discharge rapidly, less residue, good sealing and high mixing speed.

Step3: Pelletizing Process

Feed pellet machine is the most important part of the whole feed pellet production process. Our feed pellet machine got high feedback from customers for advanced product design, reasonable structure and excellent production.

Step4: Cooling Process

After pelletizing, the temperature of pellet is usually between 60-80 degrees and the moisture content is close to 15%. For storage purposes, a cooler must be used to reduce their surface temperature and prolong the storage time.

Step5: Packing Process

The feed pellet is easy to be destroy in damp conditions. In order to facilitate transport and maintain feed pellets hardness, timely packaging is necessary.

Question 1 : Is the pellet machine dry in and out?

Answer: What we usually call dry-in and dry-out means that the raw materials can be processed directly. This is a misunderstanding. It is not a real dry-in and dry-out, because the raw materials used contain a certain percentage of moisture, as long as the overall humidity is 10 Between %-15%, there is no need to add water, and it can be done directly. If the raw materials are very dry, you can spray a little water, a small amount, about 3%-5%, so that it can be formed well and will not affect storage.

Question 2 : Does the pellet machine have any requirements for raw materials?

Answer: Grain materials do not need to be crushed, but forage and straw must be crushed before they can be processed. It is best to use powder materials because the particles made from powder materials are evenly nutritious.

Question 3 : Can we not use your motors and equip them locally?

Answer: Of course, it is convenient for maintenance in the future, and can save freight! But our price is not the price of the motor! Our motors are 100% national standard copper core from regular manufacturers, the price is more expensive, and the quality Completely rest assured!

Package

1.Machines will be packed in standard and quantities boxes ,the production will have a safe and complete journey from our factory to your place.

2.Packaging details standard export wooden case or in container.

Shipping

1,We will serve your shipping method about ocean transport ,air lift ,freights and so on.

2,The delivery time is usually 7-15 working days upon receipt of your payment.

If you are looking for alfalfa Pellet machine, or want build your own pellet plant , tell us below request:

- What’s your raw material is ?

- Raw material size mm,

- Moisture content %

- Final pellet diameter mm

- Output capacity kg/h ?

Upon we get your exactly request, we propose our offer in short time.