The filling materials are clearly visible, which is convenient for feeding and cleaning at any time

- Product Details

- {{item.text}}

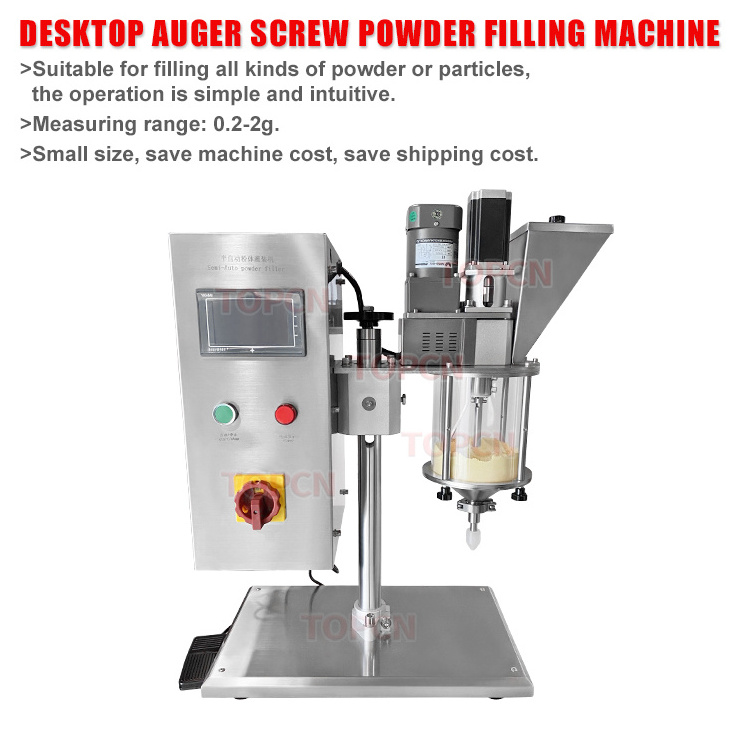

Quick Details

-

Filling Accuracy:

-

1%

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOPCN

-

Dimension(L*W*H):

-

750*360*930MM

-

Weight:

-

40 KG, 40kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Automatic powder filling machine

-

Filling method:

-

Screw metering (or electronic weighing)

-

Power:

-

1.2kw

-

Packaging volume:

-

0.2-2g (filling parts need to be replaced)

-

Hopper capacity:

-

10L

-

Filling accuracy:

-

±1%(different volume and material,accuracy will be little different)

-

Dimension:

-

750*360*930MM

-

Marketing Type:

-

New Product 2021

Quick Details

-

Machinery Capacity:

-

2000BPH

-

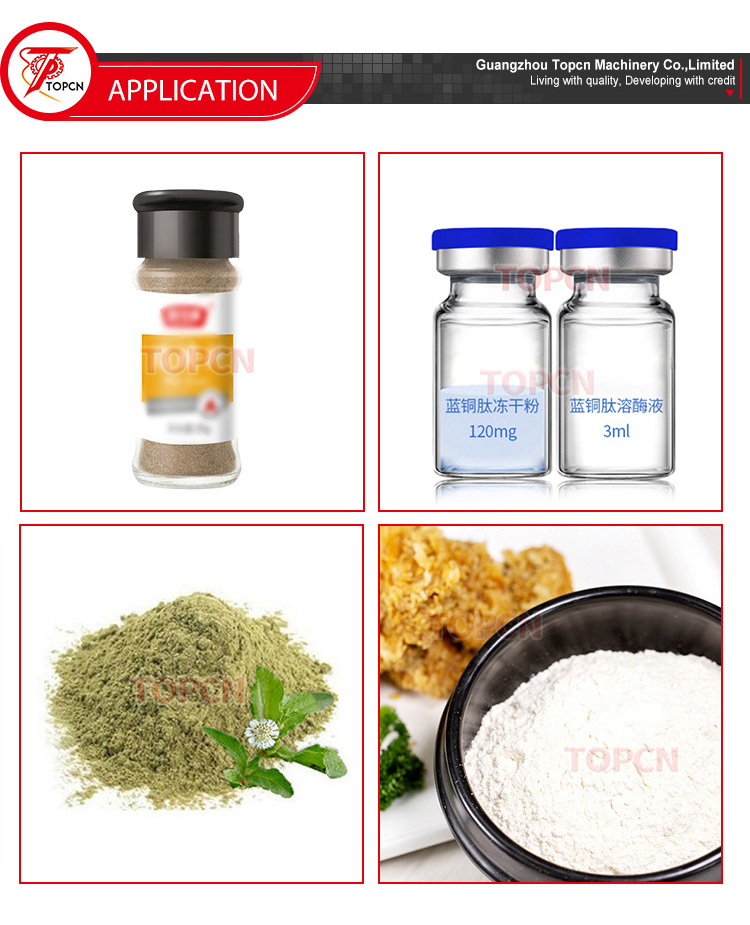

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Powder

-

Filling Accuracy:

-

1%

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOPCN

-

Dimension(L*W*H):

-

750*360*930MM

-

Weight:

-

40 KG, 40kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Automatic powder filling machine

-

Filling method:

-

Screw metering (or electronic weighing)

-

Power:

-

1.2kw

-

Packaging volume:

-

0.2-2g (filling parts need to be replaced)

-

Hopper capacity:

-

10L

-

Filling accuracy:

-

±1%(different volume and material,accuracy will be little different)

-

Dimension:

-

750*360*930MM

-

Marketing Type:

-

New Product 2021

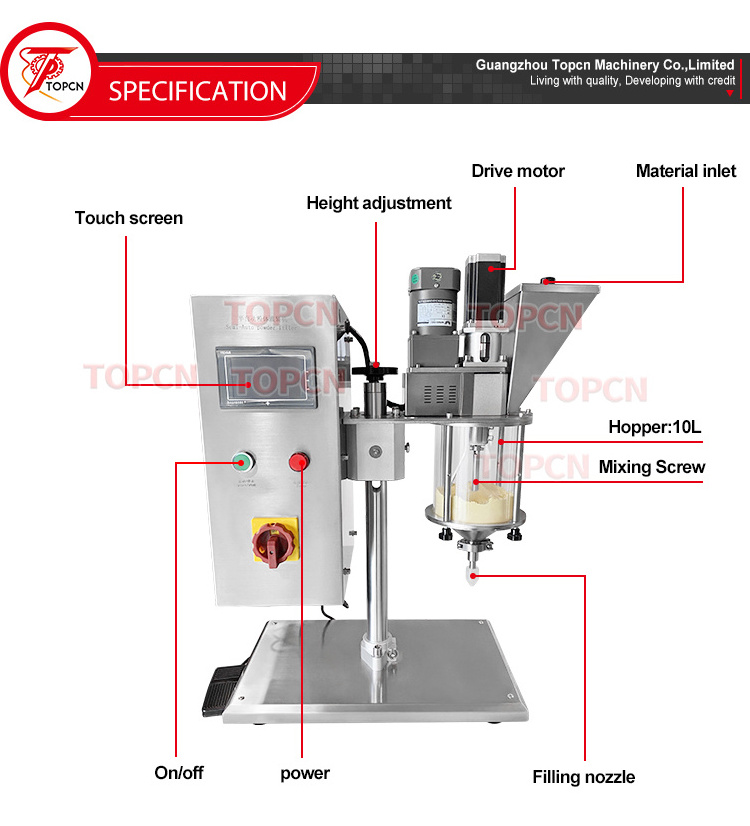

Specification

Technology Parameters:

1. This powder packing machine is integrated with machine, electricity, light and instrument. It is controlled by single chip computer. It has the functions of automatic quantification, automatic filling, automatic adjustment of measurement error and so on.

2. Stepping motor and electronic weighing technology,fast speed and high precision

3. The same quantitative packaging machine can be packed 5-5000g by adjusting and replacing filling parts of different specifications with keyboard of electronic scale.

4. Errors caused by material specific gravity and material level change can be automatically tracked and corrected.

1. This powder packing machine is integrated with machine, electricity, light and instrument. It is controlled by single chip computer. It has the functions of automatic quantification, automatic filling, automatic adjustment of measurement error and so on.

2. Stepping motor and electronic weighing technology,fast speed and high precision

3. The same quantitative packaging machine can be packed 5-5000g by adjusting and replacing filling parts of different specifications with keyboard of electronic scale.

4. Errors caused by material specific gravity and material level change can be automatically tracked and corrected.

|

Measuring method

|

Screw metering or electronic weighing

|

|

|

|

|

Power supply

|

220V 50Hz-60Hz

|

|

|

|

|

Packaging accuracy

(tested with flour)

|

≤±0.01g

|

|

|

|

|

Packaging volume

|

0.2-2g (filling parts need to be replaced)

|

|

|

|

|

Packing speed

|

≤1500bottles/min

(depending on packing specifications and materials) |

|

|

|

|

Suitable bottle height

|

60mm

|

|

|

|

|

Suitable bottle diameter

|

10mm

|

|

|

|

|

Powder

|

1.2kw

|

|

|

|

|

Hopper capacity

|

10L

|

|

|

|

|

Weight

|

40kg

|

|

|

|

|

Size

|

750*360*930MM

|

|

|

|

Hopper, filling head with quick discharges valve, fast dispatch assemble machine to working. good machine stability. Not easy to

deform.

deform.

Feeding screw lifting adjustment hand wheel. Suitable for all kinds of weighing and filling requirements.

This filling nozzle is made of stainless steel.

And the standard filling range is 0.2-2g. Special sizes can be customized according to your needs.

And the standard filling range is 0.2-2g. Special sizes can be customized according to your needs.

Stainless steel 10L hopper

The contact part between the machine and powder is made of 304 food grade stainless steel, which meets the food standard

Metering screw driven by servo motor, particularly suitable for situation with requirements. It is of high accuracy, high speed and more stability.

Related Products

Full Automatic Production Line

* Can automatically

filling liquid

, capping bottle caps and labeling stickers at the same time.

* With conveyor, it can help to save a lot of labor.

Our Services

■

1. A step-by-step free English manual and operation video to easily know how to operate the machine.

■

2. Our senior engineers are skillful and fluent in English. They have rich oversea experiences and are available to oversea services. Below with some pictures our engineers trained customers how to install and operate the machines.

Customer Evaluation

Hot Searches