- Product Details

- {{item.text}}

Quick Details

-

Cooling way:

-

Forced air cooling fan

-

Main features:

-

good compact and permeability, welding crack,soldering plate

-

Input power:

-

Single phase.AC.220V

-

Output power:

-

0.05-40KW

-

Weight:

-

13KG

-

Condition:

-

New

-

Applicable Industries:

-

Hotels

-

Certification:

-

CE, IOS 9001, CCC

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Shengzao

-

Pulse range::

-

1 -5HZ

-

Cooling way:

-

Forced air cooling fan

-

Main features:

-

good compact and permeability, welding crack,soldering plate

-

Input power:

-

Single phase.AC.220V

-

Output power:

-

0.05-40KW

-

Weight:

-

13KG

-

Condition:

-

New

-

Applicable Industries:

-

Hotels

-

Certification:

-

CE, IOS 9001, CCC

Cold tig welder Metal cold welding machine welding wire tig cold welder aluminum stainless tube copper welder no deformation shipping cost free

Welding is actually a process of melting metal by transferring heat, and then the metal is cooled and recrystallized to form a

weld. The heat output is provided by the welding machine. The output current of the welding machine and the length of the welding

time jointly determine the heat output of the welding machine. The material and thickness of the material determine the welding

heat required. (the adjustment of cold welding parameters is the process of matching the required heat and output heat of

materials) tig welding is to control the output time by manually pressing the gun switch after adjusting the current, so as to

control the heat output at one time, The problem is that the accuracy and speed of manual control is limited. Generally, the

welding time should be at least 0.3 seconds at a time. Therefore, the tig welding of materials with the same thickness can only be

welded with a small current, because it is easy to weld through with a large current. Cold welding is to precisely control the

welding time and welding interval time to millisecond level (millisecond =thousandth of a second), and the current size can be

directly adjusted according to the needs, so as to accurately control the welding heat output. Because the welding time can be

accurate to a few seconds, welding the same thickness of material can use shorter time and higher current to weld instantaneously.

Advantages of instantaneous welding: due to the short time of high current welding, the heating of materials is mainly

concentrated at the

solder joint, and the surrounding influence is small, in professional words, the heat affected zone is small. Cold welder

advantages: 01. The cold welding machine can save argon greatly. The argon consumption of cold welding machine is one fifth to two

fifths of argon gas consumption of tig welder. The argon gas separates the welding bead from the air, and the

welding spot is very white. 02. Because each welding time is precisely controlled by the cold welding machine, after adjusting the

parameters, the size and penetration of the solder joint can be consistent. When the welder operates, the welding gun can move

well. If the moving distance is the same every time, the fish scale lines with white brightness and smoothness can be welded out.

1.Welding Machine Difference

At present, there are three kinds of welding machines in the market:

01. Argon arc welding machine: the argon arc welding machine has high welding efficiency, but in the welding process, the

deformation is large, the weld joint is rough, and so on. It is the welding machine with the highest utilization rate on the

market at present. But it takes 3-5 years for argon arc welders to mature and cost a lot of labor. Limited to "people".

02. Laser welding machine: its expensive price is enough to make people hesitate.

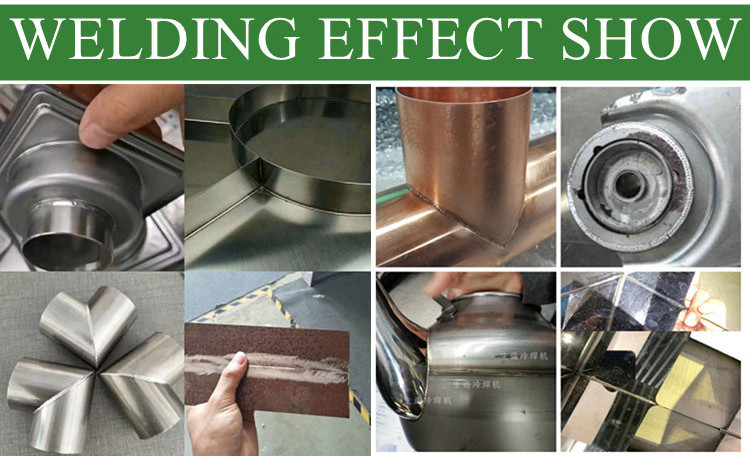

03. Precision cold welding machine: welding principle is high frequency discharge and instantaneous high temperature principle.

Its welding characteristics are silver white, small deformation, and clean fish scale. Ordinary workers are also operable,

focusing on the release of "manual". Not limited by operation and its welding characteristics, it can save a lot of labor costs

and solve the trouble caused by the follow-up process.

2. Main Functions

01. Repair cracks as this machine with good compact and permeability.

02. Soldering thin stainless steel plate, table-board, tube together.

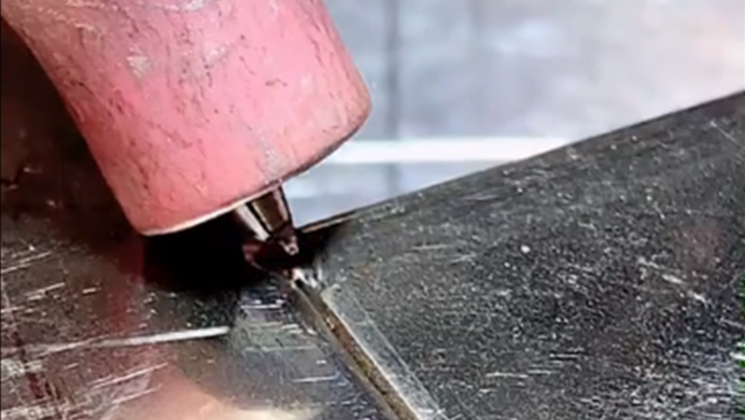

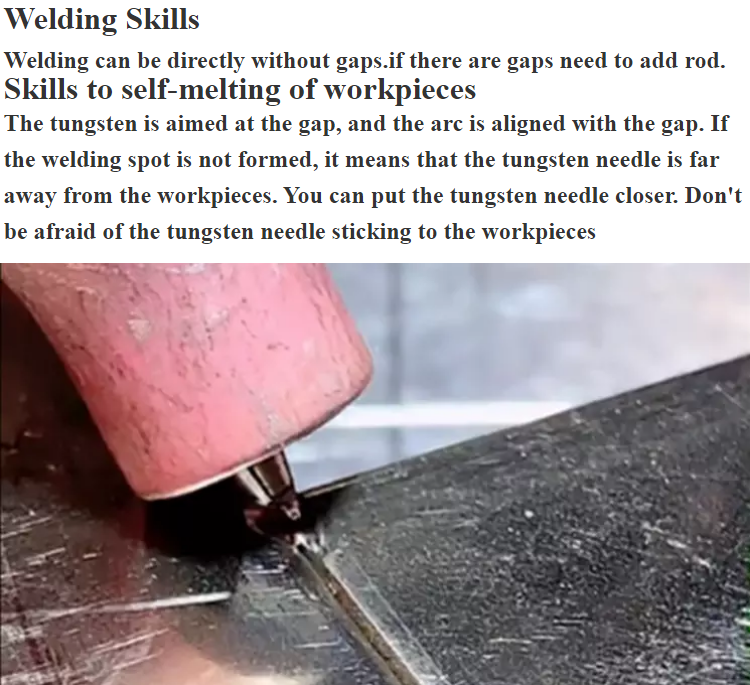

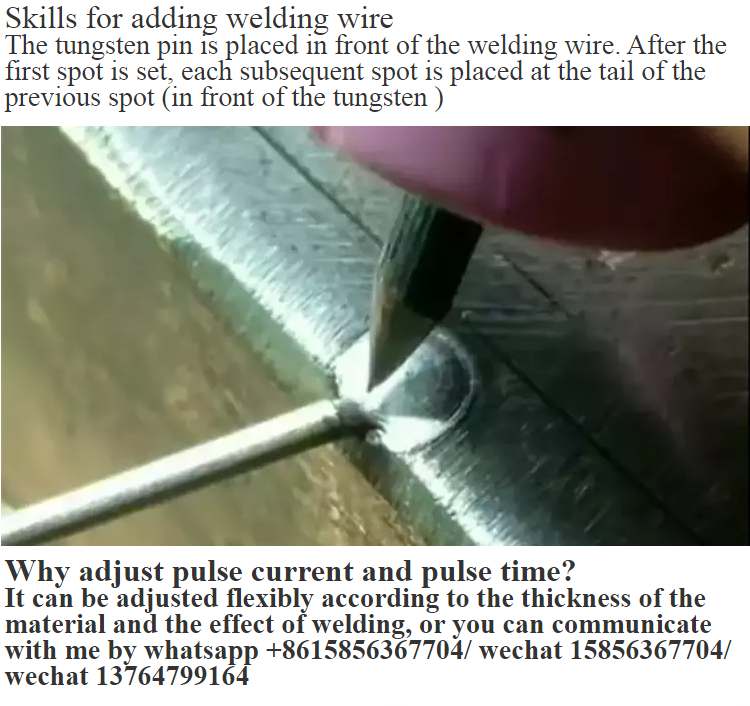

3.Application Essentials

01. Main characteristics of thin plate cold welder welding:

When CWT(Cold Welding Technology) is used to weld stainless steel sheet, the effect is obviously better than that of traditional

welding machine. It has the advantages of small output current, less heat concentration, less heat affected zone, smaller welding

deformation, uniform heat source input at all points of the weld, better control line energy, cooling effect of protecting gas

flow, reducing surface pool temperature and increasing surface tension of the weld pool, simple operation, mechanical properties

of the weld and so on. It has the advantages of good compactness and beautiful surface forming.

At present, CWT welding is widely used in all walks of life, especially in stainless steel sheet welding.

02. Splice welding:

Splice welding refers to splicing two sheets of the same thickness into one piece, or welding the rolled sheet into a whole, when

splicing welding, the splicing seam of spare parts should be small and flat.

4.Advantages

(1) Small heat affected zone while welding.

(2) No need preheating processing, no need annealing for the work pieces after welding.

(3) No deformation and edge after welding.

(4) No air hole and sand holes after welding.

(5) Precise and accurate: can weld very small and precise part, the finest wires used for welding can be 0.10mm-0.20mm.

(6) It is convenient and flexible for welding, site repair is also available.

(7)Widely used in repair all cracks, sand holes, collapse edges, corners, abrasion, etc.

(8) It is also available welding the toughing mouth of cold dies and tools. Thus exempt from the preheating, heat preservation

process of ordinary arc welder.

5.Applications and introduction

(1)Kitchen Equipment/ Stainless-steel Table Board/ Sink.

(2)Stainless-steel Products/ Stainless-steel Advertisement Characters/ Advertisement Frames/ Doors and Windows/ Light Box/ Main

Case/ Electricity Box.

(3)Available for stainless steel panel welding ( E.g. Rose Gold Plate/ Mirror Board/ Colored Stainless Steel Sheet/ Duplex

Stainless Steel/ Checkered Steel Plate/ Series P20 Stainless Steel/ Series 300 Stainless Steel etc.)

|

Model

|

SZ-1800

|

Range of welding wire

|

1.0-2.0mm

|

|

Input

|

AC 220V 50HZ

|

Welding thickness

|

0.15-6.0mm

|

|

Power

|

10-1800W

|

Cooling way

|

Forced air cooling fan

|

|

Max Power

|

>40KW

|

Weight

|

15KG

|

|

Output

|

2-200A

|

Size

|

400x220x290mm

|

|

Frequency

|

1-5HZ

|

Warranty

|

1 year

|

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you get the goods, test them and give me a feedback. If you have any questions about the problem, contact me, and I will offer the solution for you.

Factory

Our Factory

Workshop

Our Workshop

Warehouse

Our Warehouse

Team

Our Team

FAQ

Q: Are you trading company or manufacturer?

A: We are factory and manufacturer

Q: How long is your delivery time?

A: Generally it is 1-7 days.

Q: What is your terms of payment?

A: If the order quantity is less than 100pcs, 100% in advance. The order quantity is more than 100pcs, 30% T/T in advance ,balance before shippment.

If you have another question, please contact me.