- Product Details

- {{item.text}}

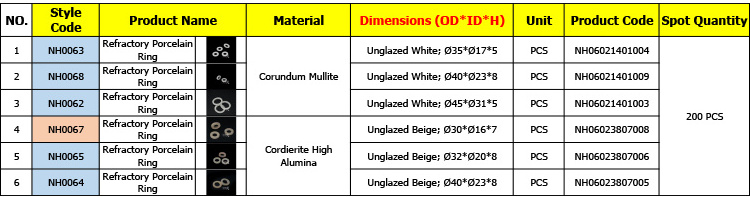

Quick Details

-

Feature:

-

High teperature resistance

-

Bulk density:

-

1.9-3.8 g/cm3

-

Length:

-

0.4-500mm

-

Package:

-

Carton/wooden

-

Fuction:

-

Insulationg ceramic

-

MOQ:

-

10

-

Color:

-

White, Yellow

-

Usage:

-

Industry Usage

Quick Details

-

Place of Origin:

-

China

-

Type:

-

Refractory Ceramic Ring

-

OEM:

-

yes

-

Feature:

-

High teperature resistance

-

Bulk density:

-

1.9-3.8 g/cm3

-

Length:

-

0.4-500mm

-

Package:

-

Carton/wooden

-

Fuction:

-

Insulationg ceramic

-

MOQ:

-

10

-

Color:

-

White, Yellow

-

Usage:

-

Industry Usage

Product Specification

|

Comparison Table of Ceramic Characteristics

|

|

|

|

|

|

|

|

|||||||

|

|

|

99 Alumina

|

95 Alumina

|

Steatite

|

Mullite

|

Cordierite

|

ZrO

2

|

|||||||

|

Main Components

|

|

99% Al

2

0

3

|

95%

Al

2

0

3

|

MgO Si0

2

|

Al

2

0

3

Si0

3

|

3Al

2

O

3

2SiO

2

|

ZrO

2

|

|||||||

|

Density

|

g/cm

3

|

3.9

|

3.6

|

2.8

|

3

|

2.5

|

6

|

|||||||

|

Water Absorption Rate

|

%

|

0

|

0

|

0

|

3

|

3

|

0

|

|||||||

|

Sintering Temperature

|

℃

|

1700

|

1680

|

1350

|

1300

|

1350

|

1600

|

|||||||

|

Hardness

|

HV

|

1700

|

1500

|

800

|

1000

|

800

|

1300

|

|||||||

|

Flexural Strength

|

Kgf/cm

2

|

3500

|

300

|

900

|

1100

|

900

|

11000

|

|||||||

|

Compressive Strength

|

Kgf/cm

2

|

30000

|

25000

|

400

|

6000

|

3500

|

25000

|

|||||||

|

Fracture Toughness

|

MPa.m1/2

|

4

|

3-4

|

-

|

-

|

-

|

-

|

|||||||

|

Maximum Operating Temperature

|

℃

|

1500

|

1450

|

1100

|

1000

|

1000

|

-

|

|||||||

|

Thermal Expansion Coefficient 0-1000℃

|

/℃

|

8*10

-6

|

8*10

-6

|

6*10

-6

|

6*10

-6

|

4*10

-6

|

9.5*10

-6

|

|||||||

|

Thermal Shock Resistance

|

T(℃)

|

220

|

220

|

200

|

300

|

250

|

360

|

|||||||

|

Thermal Conductivity

|

W/(m·K)

|

31.5

|

25

|

2.5

|

4.2

|

1.3

|

3

|

|||||||

|

|

|

15.9

|

14

|

-

|

-

|

-

|

-

|

|||||||

|

Volume Resistivity

|

Ω/cm

2

|

-

|

-

|

-

|

-

|

-

|

-

|

|||||||

|

20℃

|

|

>10

12

|

>10

12

|

>10

12

|

>10

12

|

>10

12

|

>10

12

|

|||||||

|

100℃

|

|

10

12

-10

13

|

10

12

-10

13

|

10

10

-10

11

|

10

10

-10

12

|

10

7

-10

8

|

-

|

|||||||

|

300℃

|

|

>10

12

|

>10

10

|

5*10

8

|

-

|

3*10

5

|

5*10

9

|

|||||||

|

Insulation Failure Strength

|

KV/mm

|

18

|

18

|

10

|

10

|

10

|

-

|

|||||||

|

Induced Constant

|

(E)

|

10

|

9.5

|

5.8

|

6

|

6

|

-

|

|||||||

|

(100Mhz)

|

|

|

|

|

|

|

|

|||||||

|

Induced Tangent

|

(tg6)

|

0.4*10

-3

|

0.4*10

-3

|

0.4*10

-3

|

0.4*10

-3

|

0.4*10

-3

|

-

|

|||||||

Product Characteristics of Ceramic Ceramic Ring

1. High temperature resistance

2. Long service life.

3. Good insulation.

4. Excellent thermal shock resistance and corrosion resistance.

Product Advantages

Our Customized Services

Hot Searches