- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v/50Hz, as customers' local voltage

-

Power:

-

132kw

-

Weight:

-

3000 KG, 3000kg

-

Dimension(L*W*H):

-

6500*2200*3600mm

-

Key Machines:

-

Baking Oven

-

Advantage:

-

Low Consumption High Efficiency

-

Package:

-

Wooden Case

-

Degree of automation:

-

Fully Automation

-

Automatic Grade:

-

Automatic

-

Function:

-

Multi-function

-

Processing Types:

-

Screw Extrusion

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Auris

-

Voltage:

-

220v/380v/50Hz, as customers' local voltage

-

Power:

-

132kw

-

Weight:

-

3000 KG, 3000kg

-

Dimension(L*W*H):

-

6500*2200*3600mm

-

Key Machines:

-

Baking Oven

-

Advantage:

-

Low Consumption High Efficiency

-

Package:

-

Wooden Case

-

Degree of automation:

-

Fully Automation

-

Automatic Grade:

-

Automatic

-

Function:

-

Multi-function

-

Processing Types:

-

Screw Extrusion

Product Description

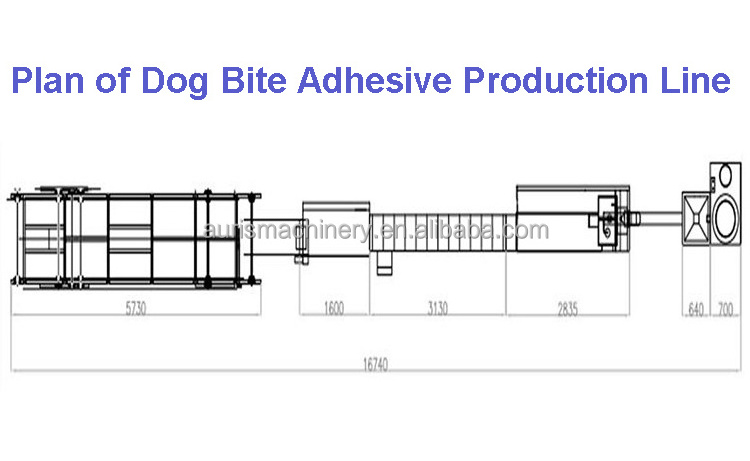

Animal Pet Dog Food Making Machine Manufacturing Equipment Processing Plant Production Line

Selling Pet food processing line/Plant/Machinery lant is a newly-designed line for

improving market of pet food, which is developed successfully with our many years research experiences on food machinery. This line endues pet food with novel shape, unique taste and color. It can meet with other needs of modern market by many superior characteristics, such as scientific nutrition formular and easy assimilation

improving market of pet food, which is developed successfully with our many years research experiences on food machinery. This line endues pet food with novel shape, unique taste and color. It can meet with other needs of modern market by many superior characteristics, such as scientific nutrition formular and easy assimilation

1.Production Description

* Materials: Corn powder, Wheat flaour,Fish powder, bone powder,etc and water.

* Capacity : 100-160kg/h,200-260kg/h, 400-500kg/h,800-1500kg/h,2-3t/h,4-6t/h

* Consumption: Low electricity and labor consumption

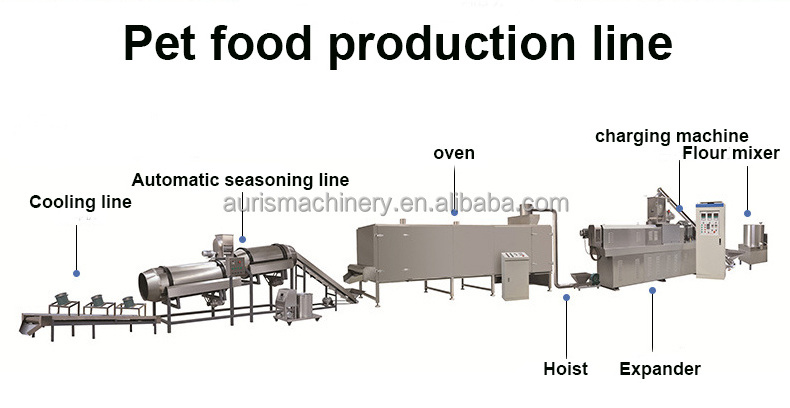

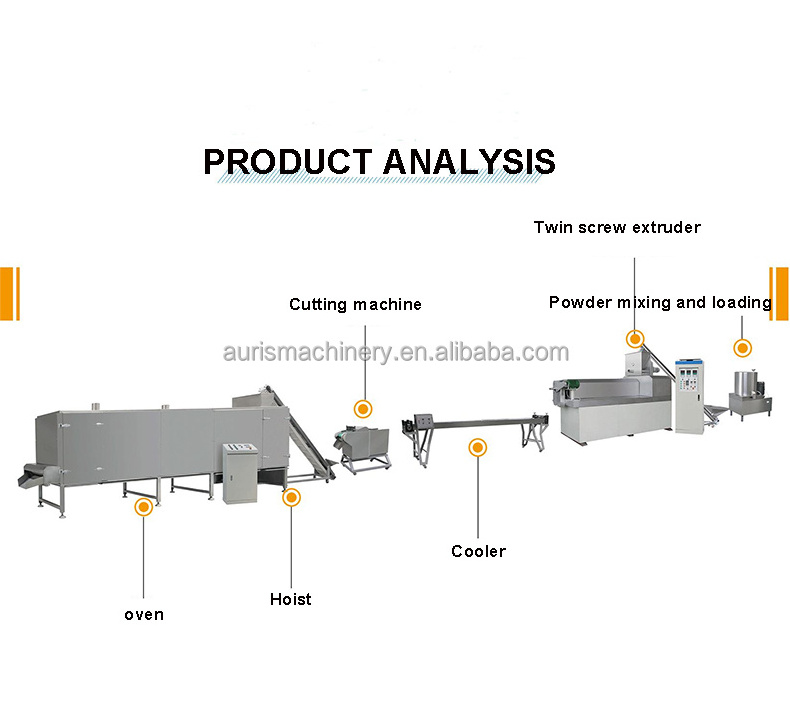

2.Technological Process

* Raw material---Mixing---Screw Conveying---Extruding---Air Conveying---Roasting---Air Conveying---Flavoring---Cooling

3.Equipments List:

* Mixer --Screw Conveyor --Twin Screw Extruder--Air Conveyor--Multi-Layer Oven--Roller --Oil Sprayer--Flavor Roller

* Ribbon Blender---Bucket Elevator---Storage Hopper---Conditioner---Twin Screw Extruder---Air Conveyor---Seven layer dryer---Air Conveyor---Oil Sprayer---Flavoring Roller---Cooling Conveyor---Air Conveyor---Sifter---Air Conveyor

4.Main Feature:

1. Big Capacity Feeding Hopper, Variable Frequency Speed, Two Stages Mixing Wings ensure the Fast and Efficient Mixing and Feeding.

* Materials: Corn powder, Wheat flaour,Fish powder, bone powder,etc and water.

* Capacity : 100-160kg/h,200-260kg/h, 400-500kg/h,800-1500kg/h,2-3t/h,4-6t/h

* Consumption: Low electricity and labor consumption

2.Technological Process

* Raw material---Mixing---Screw Conveying---Extruding---Air Conveying---Roasting---Air Conveying---Flavoring---Cooling

3.Equipments List:

* Mixer --Screw Conveyor --Twin Screw Extruder--Air Conveyor--Multi-Layer Oven--Roller --Oil Sprayer--Flavor Roller

* Ribbon Blender---Bucket Elevator---Storage Hopper---Conditioner---Twin Screw Extruder---Air Conveyor---Seven layer dryer---Air Conveyor---Oil Sprayer---Flavoring Roller---Cooling Conveyor---Air Conveyor---Sifter---Air Conveyor

4.Main Feature:

1. Big Capacity Feeding Hopper, Variable Frequency Speed, Two Stages Mixing Wings ensure the Fast and Efficient Mixing and Feeding.

2. Conditioner, Available for Steam, Pre-cooking and High Efficient.

3. Unique Designed Round Barrels, Made by Hard Carbide Sleeve, Hard-wearing and Durable.

4. Modular Circular Groove Screws, available for Different Extrusion Rate Applications.

5. Steam Heating System, ensure the Most Efficient, Continuous and Stable Heating Effects.

6. Worldfamous Brands Electronic Apparatus used in the Controller Box, make sure the Extrusion Process Perfect

7. Main Motor ensure its Powerful Extrusion and Excellent Performance

3. Unique Designed Round Barrels, Made by Hard Carbide Sleeve, Hard-wearing and Durable.

4. Modular Circular Groove Screws, available for Different Extrusion Rate Applications.

5. Steam Heating System, ensure the Most Efficient, Continuous and Stable Heating Effects.

6. Worldfamous Brands Electronic Apparatus used in the Controller Box, make sure the Extrusion Process Perfect

7. Main Motor ensure its Powerful Extrusion and Excellent Performance

Hot Searches