ALD-2209, it is a high performance, two components with mix ratio of 1:1, Clear epoxy Coating and Casting system, pourable, self-leveling and is scratch and water resistant, leaving you with THE HIGHEST SUPER WET GLOSS finish with unparalleled depth and clarity. It is formulated

to use within all coating and step casting applications such as Coating on Coffee Tables, Step Pour River Tables, Side Tables, Bar Tops, Counter tops, Small Void Filling Live-Edge Tables. If you have a

large project, make sure to mix up no more than a Half Gallon at a time. Step Casting on Art, DIY Crafts, DIY Flowers Crafts, Jewelry, River Tables and so on.

This product is mass dependent, meaning the more you mix, the quicker, it cures, and the less working time you will have.

We Are the Original Manufacturer, and We've Been in this Business

Since 1998

DIRECTIONS FOR USE:

Step 1:

The ideal working temperature is around a constant 77°F. Best results can be obtained at constant temperatures between 70°F and 85°F, in a clean, dry, dust-free environment. Avoid working in high humidity. We recommend using this product on a leveled and flat work surface.

Step 2:

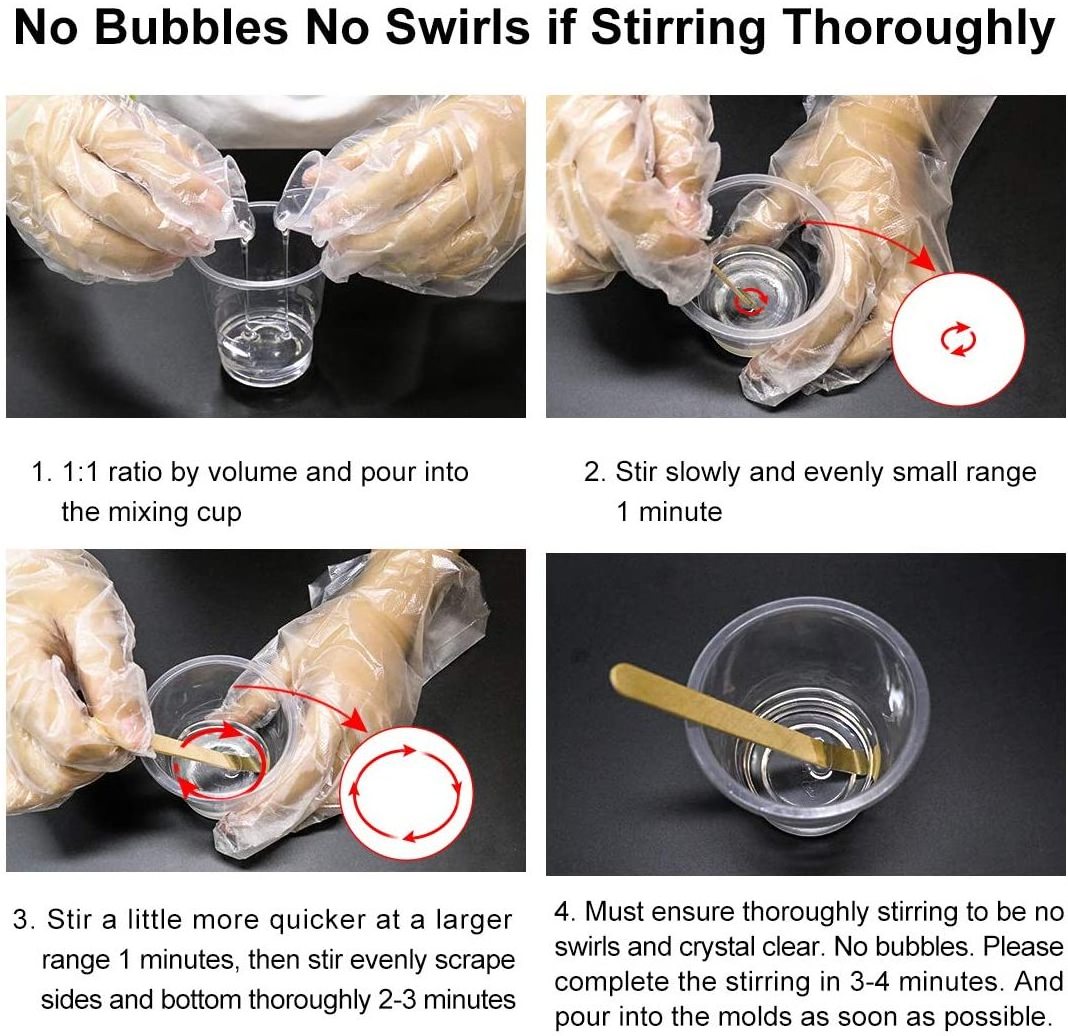

Measure product in accordance with your intended use. Prepare 1 part Base Resin to 1 part Curing Agent by liquid volume. Pour the Curing Agent first and then the Base Resin into a clean, smooth-sided container large enough to hold all the liquid and allow room for mixing.

Step 3:

The material must be mixed thoroughly for at least 3 minutes. Be sure to scrape the container sides, bottom, and corners as you mix. Be careful not to whip excessive air into the mixture. If mixing a gallon, use a power mixer set to “hand speed.” For smaller quantities, use stir sticks. Do not mix more than a gallon. Pour into a new, clean container and mix for an additional minute.

Step 4:

Pour the mixed resin onto the surface and distribute evenly with a squeegee or gloved hand. Continue to pour remaining material to achieve the desired thickness, allowing the resin to flow evenly over the project’s sides. Resin can be poured up to 1/4” thick per pour.

Step 5:

Use a heat source such as a heat gun to remove any bubbles by adding a small amount of heat to the surrounding area. The bubble will rise to the surface and pop.

Step 6:

If you are going to make a second pour, the first pour should still be slightly sticky. Once the second pour is made, bubbles may once again need to be removed. Material will feel hard after 45-60 minutes, cure to the point of workability within 24 hours, but full cure and maximum hardness can require up to 7 days, depending upon the temperature.

PRO TIP:

If you wish to apply paper decals or other objects under the Super clear counter top epoxy surface, those objects need to be bonded to the surface either with Super Clear Epoxy or craft glue. Some wood may take the material well in a single coat; however, many types of wood require a seal coat to prevent air bubbles from rising out of the wood and ruining the surface. Older, more porous pieces of wood may contain both air and moisture that can contaminate the finish. In this case,

the user may first paint on a very thin coat of our ALD-2209, allowing that to set before pouring the new layer.