- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

160 mm

-

Ejector Force(kN):

-

62 kN

-

Theoretical Shot Volume(cm³):

-

707 cm³

-

Injection Rate (g/s):

-

1305 g/s

-

Injection Weight (g):

-

447 g

-

Screw Speed (rpm):

-

1 - 204 rpm

-

Screw diameter (mm):

-

50 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

534*534mm

-

Weight (KG):

-

6200 kg

-

Place of Origin:

-

Tianjin, China

-

Open Stroke(mm):

-

490 mm

-

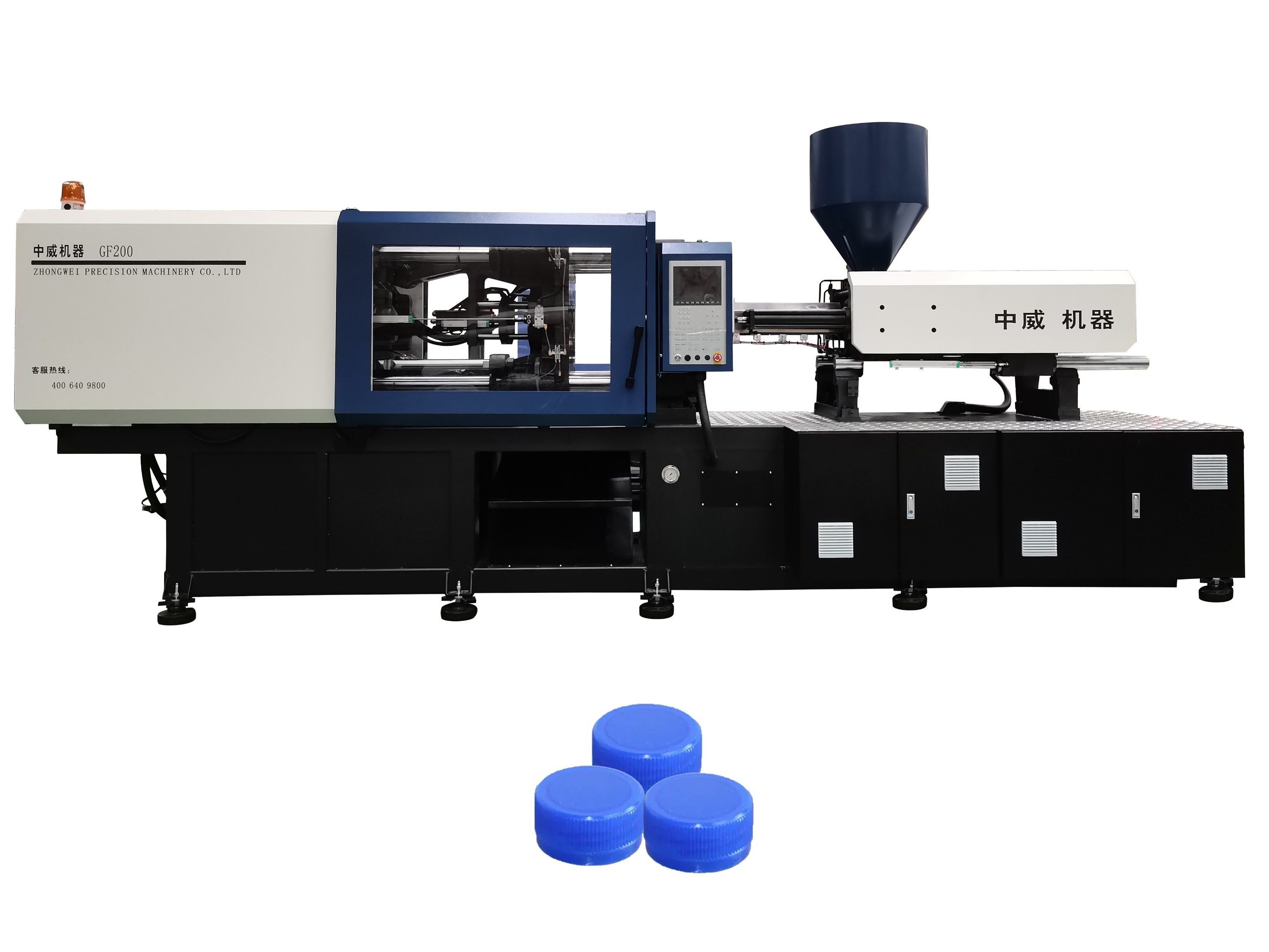

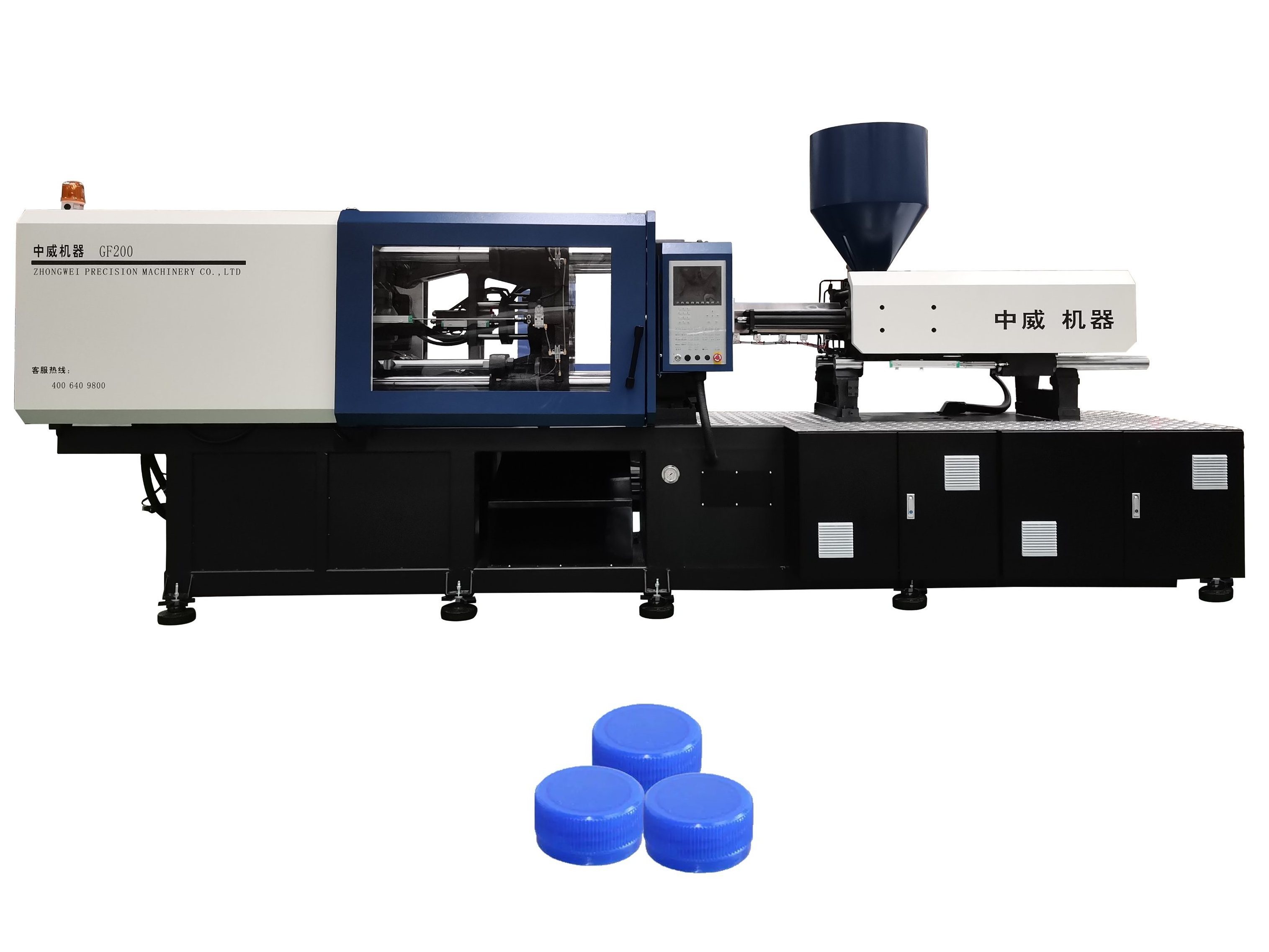

Model Number:

-

GF200EH

-

Brand Name:

-

ZOWEITE

-

Power (kW):

-

21 kW

-

Product name:

-

Injection Molding Machines

-

Model:

-

GF200EH

-

BRAND:

-

ZOWEITE

-

Function:

-

plastic parts production

-

Application:

-

Inserting Plastic Products

-

Motor:

-

Servo Energy Saving

-

Machiner Dimensions(mm):

-

5600*1600*2400

-

Machine Color:

-

white+blue

-

Advantage:

-

energy saving

-

stable performance:

-

short cycle time

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

534mm

-

Distance between Tie Bars(Height)(mm):

-

534mm

-

Mold Height(mm):

-

170 - 600 mm

-

Ejector Stroke(mm):

-

160 mm

-

Ejector Force(kN):

-

62 kN

-

Theoretical Shot Volume(cm³):

-

707 cm³

-

Injection Rate (g/s):

-

1305 g/s

-

Injection Weight (g):

-

447 g

-

Screw Speed (rpm):

-

1 - 204 rpm

-

Screw diameter (mm):

-

50 mm

-

Screw L/D Ratio:

-

20

-

Distance between Tie Bars:

-

534*534mm

-

Weight (KG):

-

6200 kg

-

Place of Origin:

-

Tianjin, China

-

Open Stroke(mm):

-

490 mm

-

Model Number:

-

GF200EH

-

Brand Name:

-

ZOWEITE

-

Power (kW):

-

21 kW

-

Product name:

-

Injection Molding Machines

-

Model:

-

GF200EH

-

BRAND:

-

ZOWEITE

-

Function:

-

plastic parts production

-

Application:

-

Inserting Plastic Products

-

Motor:

-

Servo Energy Saving

-

Machiner Dimensions(mm):

-

5600*1600*2400

-

Machine Color:

-

white+blue

-

Advantage:

-

energy saving

-

stable performance:

-

short cycle time

-Machine Introduction-

ZOWEITE GF200EH injection molding machine is servo system machine. ZOWEITE do not only provide machine technology but also provide injection system solutions to help our customers gain advantages in the current market competition.

|

Technical Parameter

|

|

GF130

|

GF200

|

GF260

|

GF320

|

GF400

|

GF530

|

GF650

|

GF780

|

|

|

Screw Diameter

|

mm

|

50

|

55

|

55

|

65

|

75

|

85

|

90

|

95

|

|

|

Max. Shot Weight(PS)

|

g

|

240

|

447

|

573

|

921

|

1507

|

2293

|

2952

|

3280

|

|

|

Injection Pressure

|

Mpa

|

175

|

205

|

200

|

169

|

191

|

178

|

177

|

193

|

|

|

Clamping Force

|

KN

|

1300

|

2000

|

2600

|

3200

|

4000

|

5300

|

6500

|

7800

|

|

|

Opening Stroke

|

mm

|

400

|

490

|

550

|

630

|

720

|

790

|

900

|

990

|

|

|

Space Between Tie Bars(W*H)

|

mm

|

470*420

|

534*

534

|

590*590

|

662*615

|

740*700

|

820*800

|

920*868

|

960*940

|

|

|

Max. Mold Height

|

mm

|

480

|

720

|

600

|

650

|

720

|

820

|

950

|

1000

|

|

|

Min. Mold Height

|

mm

|

150

|

340

|

220

|

250

|

340

|

370

|

400

|

450

|

|

|

Hydaulic System Pressure

|

Mpa

|

17.5

|

14

|

16

|

16

|

16

|

16

|

16

|

16

|

|

-Details Images-

Digital control system uses a dedicated controller, multiple CPU processing units, a multi-function automatic fault detection, alarm system, can verify 99 processing program molds, and has a remote control interface.

Infrared heating, fast temperature rise and good thermal insulation effect.Stable machine performance and high energy saving rate.

The tie rods are made of high quality structural alloy steel plated with hard chromium, with high mechanical strength and fatigue strength.

With double guide posts and dual-cylinder balance injection device, guarantees that balanced and uniform forces are applied on the screw during injection and moving forward.

High-precision electronic detection device, multi-level control of travel, speed and position, positioning accuracy.The safety door is equipped with a triple safety device of hydraulic, mechanical and electrical interlock.

Multi stages controlling of mold clamp pressure, speed and position.Mold thickness can be adjusted through ring gear which is driven by hydraulic oil motor.

Hot Searches