- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V /CUSTOMIZED

-

Dimension(L*W*H):

-

300000*6000*80000MM

-

Weight:

-

5000 kg

-

Item:

-

pig feed pellet making machine pig feed pellet poultry feed equipment

-

Structure:

-

full-opened door

-

Material:

-

stainless or carbo steel

-

Capacity:

-

1-15T/H

-

Evenness:

-

not less than 90%

-

Feeding methods:

-

manual or automatic feeding

-

Power:

-

electric motor

-

Application:

-

feed processing

Quick Details

-

Max. Capacity:

-

1ton/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SDSH

-

Voltage:

-

220V /CUSTOMIZED

-

Dimension(L*W*H):

-

300000*6000*80000MM

-

Weight:

-

5000 kg

-

Item:

-

pig feed pellet making machine pig feed pellet poultry feed equipment

-

Structure:

-

full-opened door

-

Material:

-

stainless or carbo steel

-

Capacity:

-

1-15T/H

-

Evenness:

-

not less than 90%

-

Feeding methods:

-

manual or automatic feeding

-

Power:

-

electric motor

-

Application:

-

feed processing

animal feed corn gluten meal feed granule making machine for fish liquid molasses cattle feed with good price

Hot sale pig feed pellet making machine pig feed pellet production line poultry feed equipment with good quality is a complete set of crusher, twin-shaft paddle mixer, cooler, vibrating screen, silo, bucket elevator and crusher. It is suitable for the production of large-scale farms and medium-sized feed factories. It occupies a small area, has a compact structure, is easy to install, consumes less energy, and is easy to operate.It can produce a variety of feed types. Such as: pig feed, chicken feed, duck feed, pigeon feed, quail feed, livestock pellet feed and poultry feed, powder feed and pellet feed, full price feed, additive feed and so on.

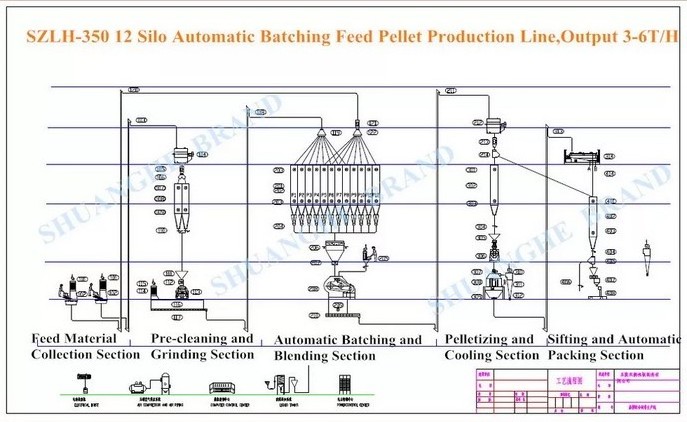

Flow chart of animal feed corn gluten meal feed granule making machine for fish liquid molasses cattle feed with good price

The material enters the granulator from the silo through the discharger, hoist and magnetic separation device, and the granulated feed extruded from the granulator needs to be cooled by the cooler because of its high temperature and moisture. The cooled pellet feed can enter into the granulator or only into the grading sieve, and the finished product from the grading sieve enters the finished product warehouse through the conveyor.

The following matters should be paid attention to in the arrangement of the granulation process:

1. In order to change the feed formula, there should be at least two mixture silos before the pellet mill. In this way, one silo continues to feed the pellet mill, while the other silo can be filled with the new formula. These bins shall be equipped with mechanical discharge devices.

2. Before the granulator, an efficient metal removal electromagnetic device must be installed to protect the die.

3. It is better to install the granulator on the cooler, so that the fragile hot and damp granules from the granulator can directly enter the cooler. The granulator can be installed under the cooler, and the crumbs or granules are sent to the upper grading sieve through the elevator, so that the return of the fine powder and the sieve is convenient.

4. The sieved granules should be conveyed by belt conveyor or other conveying equipment for unbreakable granules.

5. The finished product should be packaged after the product warehouse, not directly after granulation. Because the temperature and moisture of the extruded pellets are high, it is necessary to cool and classify to reduce the moisture to increase the hardness of the pellets.

Application for animal feed corn gluten meal feed granule making machine for fish liquid molasses cattle feed with good price

Animal feed production line can be used to make various poultry feed and aquatic feed for rabbits, ducks, cattle, chickens, sheep, pigs, pigeons, fishes and shrimp etc. The whole production line can be control by the automatic PLC control system.

Features & Advantages

a. Equipped with motors with different voltages, the mixer's capacity ranges from 100KGS to 2000KGS, which is nicely suitable to small, medium and large scale feed factories.

b. Novel rotor structrue keeps mixing uniformity without segregation.

c. Chain-driving design keeps stable transmission.

d. Installing oil pipelines makes overall structure of the machine is more reasonable and aesthetic.

e. Double layers design on two ends of the machine prevents materials from leaking.

f. Three opening ways of the discharging port can be choosable: penumatical; electric; manual.

g. The gap between the rotor and the machine enclosure can be adjustable, which makes

large door or full door design on the bottom of the machine become possible.

Technical parameters for 3-5T/H Animal Poultry Cattle Chicken Fish Feed Pellet Making Machine Cattle Feed Pellet Mill Form A to Z for Sale:

|

Model |

SHJ-100 | SHJ-250 | SHJ-500 | SHJ-1000 | SHJ2000 | SHJ-3000 | SHJ-5000 |

| Capacity(kg/batch) | 100 | 250 | 500 | 1000 | 2000 | 3000 | 5000 |

| Power(kw) | 3 | 4 | 11 | 22 | 30 | 37 | 45 |

| Actual volume(m3) | 0.35 | 0.59 | 1.15 | 2.28 | 4.4 | 6.8 | 11.5 |

| CV 5% |

| Mixing times(Min) 3~5min |

Except SHJ series feed mill mixer , there are feed mill mixers to be choosable for you.

Double Crane are able to choose a more adapted packing ways for you such as wooden case and iron case. Pls kindly tell us your idea, we will immediately design a better project with reasonable shipping charges and reliable packing to suit to your requirements.

a. Technical support online service provided.

b. Technical files service provided.

c. On-site training service provided.

d. Spare parts replacement and repair service provided.