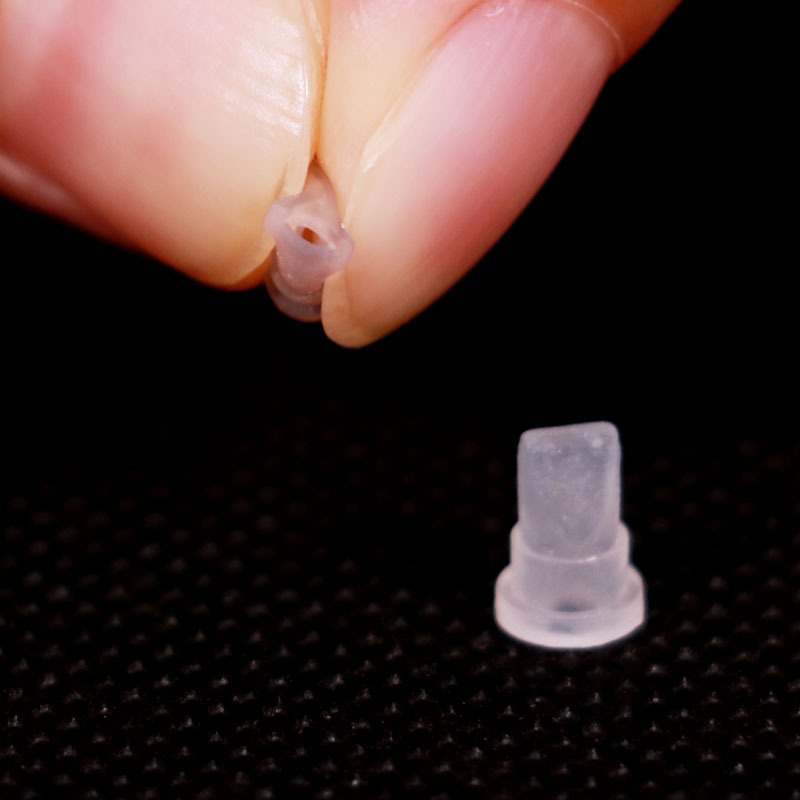

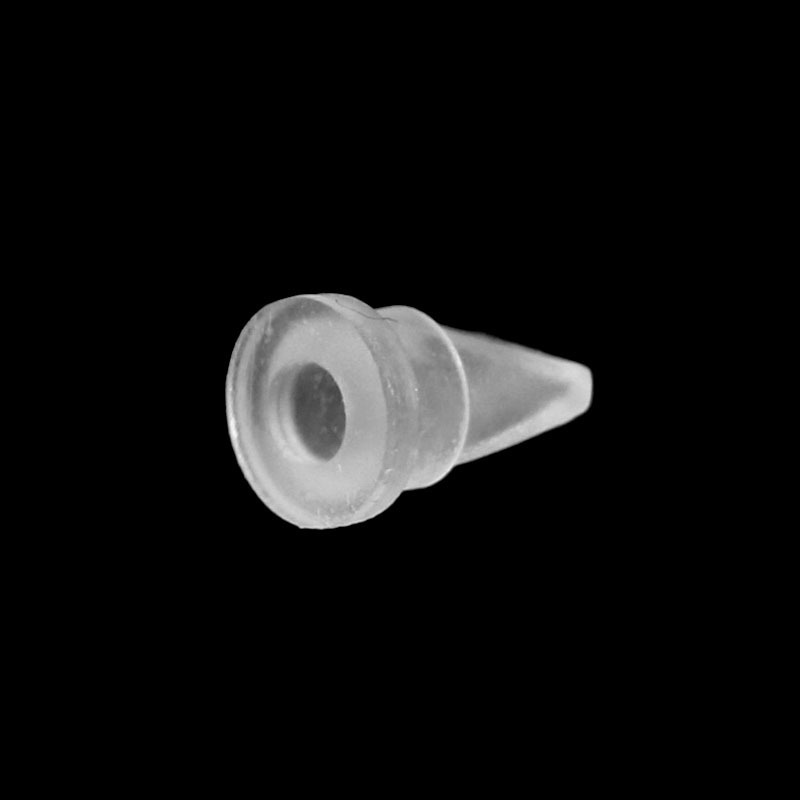

- The silicone rubber duckbill valve is no spill, no leakage and airtight.- One way duckbill check valve

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

XFSV03

-

Process:

-

LSR Injection Molding

-

Material:

-

LFGB Approved Liquid Silicone

-

Hardness:

-

40 Shore A

-

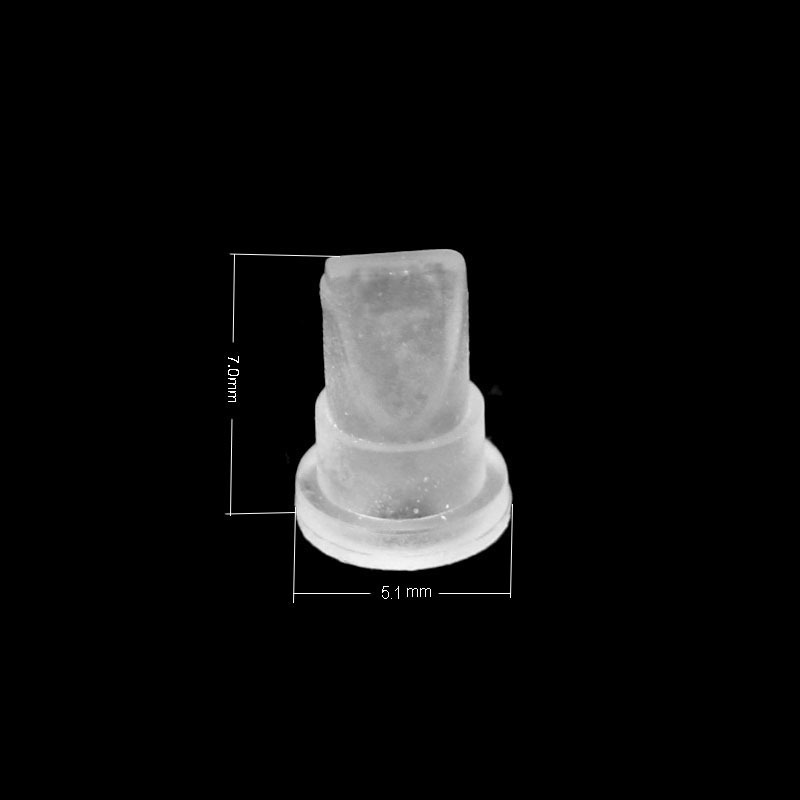

O.D.:

-

5.1MM

-

Lenght:

-

7mm

-

Function:

-

Flow Control Valve

-

Color:

-

Clear

-

Free Samples:

-

Yes

-

Application:

-

Food/Medical

-

Certification:

-

SEDEX, ISO9001, ISO14001

Quick Details

-

Processing Service:

-

Moulding, Cutting, Punching

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

XFSV03

-

Process:

-

LSR Injection Molding

-

Material:

-

LFGB Approved Liquid Silicone

-

Hardness:

-

40 Shore A

-

O.D.:

-

5.1MM

-

Lenght:

-

7mm

-

Function:

-

Flow Control Valve

-

Color:

-

Clear

-

Free Samples:

-

Yes

-

Application:

-

Food/Medical

-

Certification:

-

SEDEX, ISO9001, ISO14001

Product Description

|

Product Information

|

|

|

|

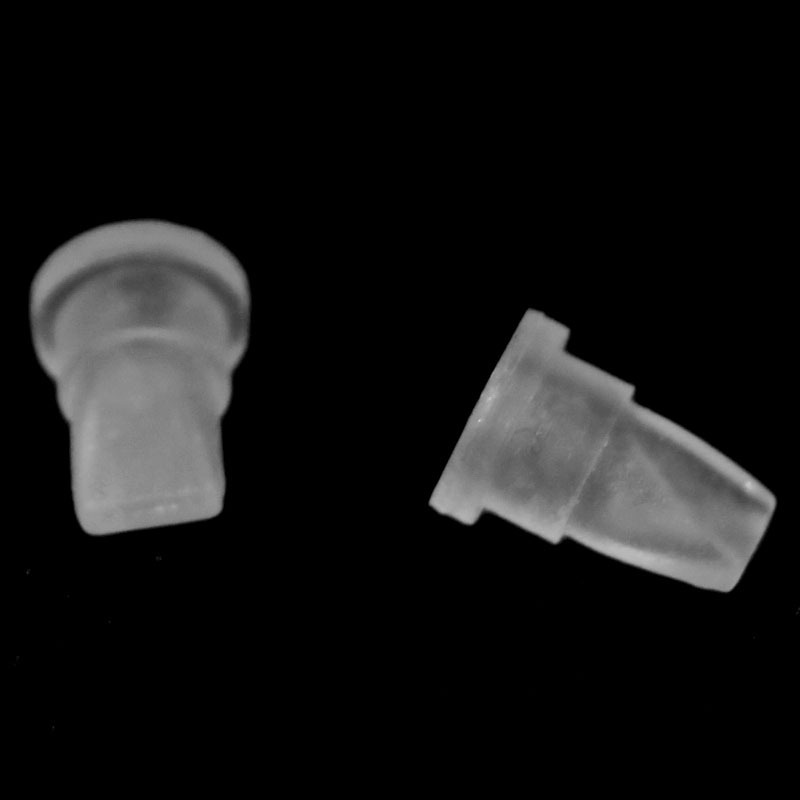

*Name

|

Customized One Way Silicone Rubber Duckbill Flap Check Valve

|

|

|

*Material

|

LFGB Approved Food Grade Liquid Silicone

|

|

|

*O D

|

5.1mm

|

|

|

*

Lenght

|

7.0mm

|

|

|

*Punching

|

Cross Slit, Snowflake, etc.

|

|

|

*Process

|

LSR Injection Molding- Baking- Inspection- Punching- Inspection- Packing- Shipping

|

|

|

*Hardness

|

40 Shore A or Customized

|

|

|

Feature

|

One Way Flow Control Valve, No Drip, No Leakage

|

|

|

Function

|

Dispensing Control

|

|

|

Temperature Resistant

|

-40 ℃ to 220 ℃

|

|

|

*Color

|

Clear

|

|

No Leakage One Way Silicone Rubber Duckbill Check Valve

- The silicone rubber duckbill valve is no spill, no leakage and airtight.- One way duckbill check valve

How it works

In the absence of internal pressure the duck bill outlet closes under its own elasticity. As the internal pressure gradually increases, the duck bill outlet gradually increases keeping the liquid drained at high flow rates. The valve opens when the appropriate pressure fluid gas passes through the valve.When the flow rate or pressure increases, the opening degree of the duckbill valve also increases When the water flow stops the backwater pressure or atmospheric.

Application

Due to the convenient opening and closing of the duckbill valve and good sealing, it can effectively prevent the backflow of liquid and gas and meet the application requirements in many

fields,such as medical equipment,

machinery, and equipment daily

equipment irrigation.

equipment irrigation.

Recommend Products

Detailed Images

-

-

Flow Control Silicone Slit Valve

-

Silicone Control Valve

-

Leak Proof Silicone Slit Valves

Product Description:

1. Made of food grade premium silicone raw materials, certified by LFGB.2. Processed by LSR injection molding, airtight

silicone rubber duckbill check valve.

3. Leak proof silicone duckbill check valve for electronics.

4. Temperature resistant from -40 Celsius degrees to 240 Celsius degrees.

5. No spill and no drip silicone duckbill valve, welcome to custom made.

6. Xufusilicone specializes in producing silicone products for over 16 years, welcome OEM and ODM orders.

silicone rubber duckbill check valve.

3. Leak proof silicone duckbill check valve for electronics.

4. Temperature resistant from -40 Celsius degrees to 240 Celsius degrees.

5. No spill and no drip silicone duckbill valve, welcome to custom made.

6. Xufusilicone specializes in producing silicone products for over 16 years, welcome OEM and ODM orders.

Company Introduction

Dongguan Xufu Rubber& Plastic Co., Ltd.

was founded in 2008, with over 16 years of

experience in producing rubber and plastic products and 13 years of experience in serving customers from Europe and Japan.

Our main products are reusable silicone kitchenware products, silicone baby products, medical silicone parts, menstrual cups and other customized silicone products.

Our company covers 5000 square meters workshop, with 10 sets compression molding machines, 1 set LSR injection molding machine and 3 sets plastic injection machine, also has certified by SEDEX, ISO9001 and ISO14001.

Highly welcome OEM and ODM orders.

experience in producing rubber and plastic products and 13 years of experience in serving customers from Europe and Japan.

Our main products are reusable silicone kitchenware products, silicone baby products, medical silicone parts, menstrual cups and other customized silicone products.

Our company covers 5000 square meters workshop, with 10 sets compression molding machines, 1 set LSR injection molding machine and 3 sets plastic injection machine, also has certified by SEDEX, ISO9001 and ISO14001.

Highly welcome OEM and ODM orders.

Certifications

FAQ

Q: Are you factory or trading company?

A: We are a factory with over 16 years manufacturing experience.

Q: Can I have customized design?

A: Yes, we highly welcome OEM or ODM orders.

Q: What shall I offer if I want to custom?

A: You can offer us the 3D/ 2D drawings or samples for checking.

Q: Can I get free samples?

A: Yes, free samples can be offered for quality confirmation. Shipping costs to be freight collect.

Q: What’s your MOQ?

A: For this flow control silicone cross slit valve, the MOQ is only 10,000pcs.

A: We are a factory with over 16 years manufacturing experience.

Q: Can I have customized design?

A: Yes, we highly welcome OEM or ODM orders.

Q: What shall I offer if I want to custom?

A: You can offer us the 3D/ 2D drawings or samples for checking.

Q: Can I get free samples?

A: Yes, free samples can be offered for quality confirmation. Shipping costs to be freight collect.

Q: What’s your MOQ?

A: For this flow control silicone cross slit valve, the MOQ is only 10,000pcs.

Q: Can I custom made the cross slit?

A: Yes, highly welcome custom made you own slit size of the silicone slit valve.

Q: Can I visit your factory?

A: Highly welcome to visit our factory at your convenience.

For more details, you can contact us directly.

Q: Can I visit your factory?

A: Highly welcome to visit our factory at your convenience.

For more details, you can contact us directly.

Hot Searches