- Product Details

- {{item.text}}

Quick Details

-

Application:

-

aluminum,Metal,steel,copper,cast iron,stainless steel

-

Keyword:

-

briquetter press machine

-

Press Force:

-

100-630 tons

-

Bale Diameter:

-

90-200mm

-

Motor:

-

11-135KW

-

System Pressure:

-

25 mpa

-

Capacity Aluminum:

-

100-1000kg/h

-

Capacity Steel:

-

200-4000kg/h

-

Operation:

-

Automatic Operation

-

Power type:

-

Electric Motor

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ENERPAT

-

Weight (KG):

-

3000

-

Application:

-

aluminum,Metal,steel,copper,cast iron,stainless steel

-

Keyword:

-

briquetter press machine

-

Press Force:

-

100-630 tons

-

Bale Diameter:

-

90-200mm

-

Motor:

-

11-135KW

-

System Pressure:

-

25 mpa

-

Capacity Aluminum:

-

100-1000kg/h

-

Capacity Steel:

-

200-4000kg/h

-

Operation:

-

Automatic Operation

-

Power type:

-

Electric Motor

Product Description

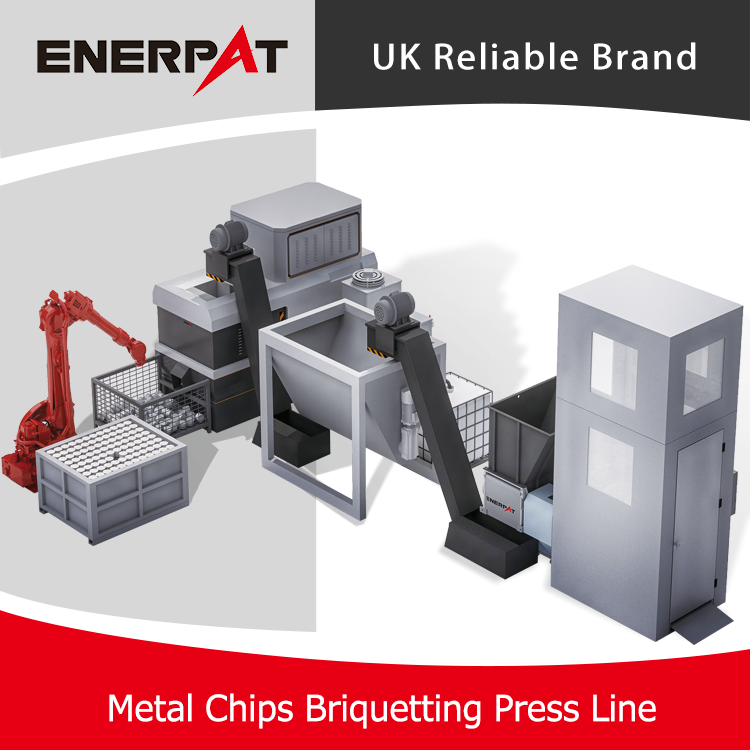

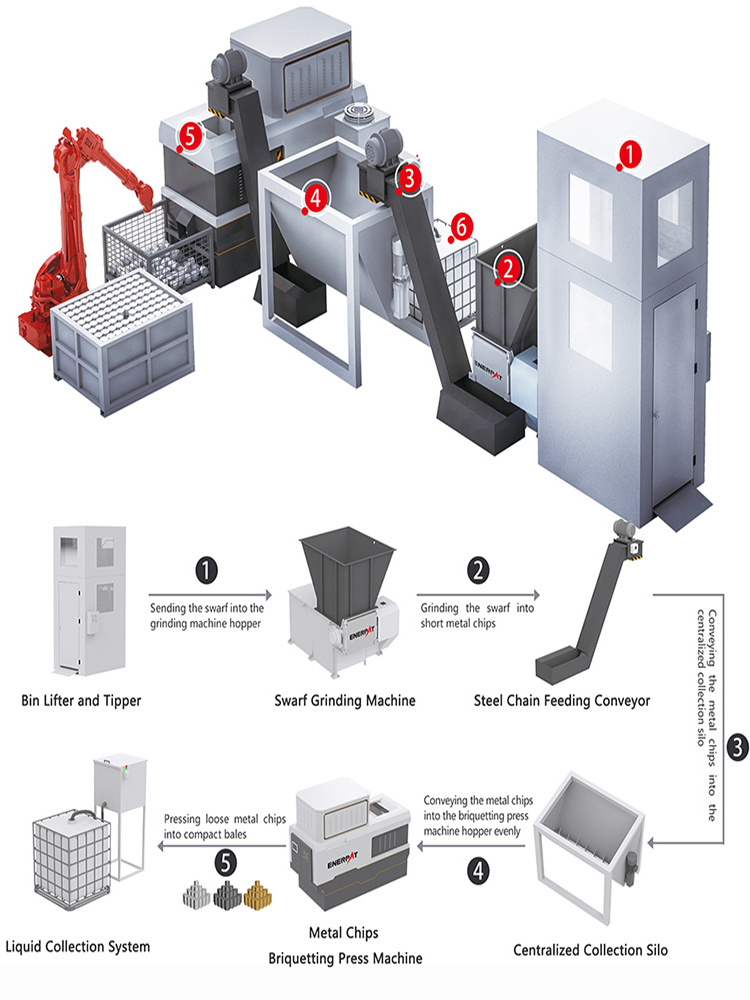

Metal Chips Briquetting Press Line

This Metal Chips Briquetting Press System combined with six integrated units,working closely coordinated under the control of PLC,interlocking and precise cooperation.

Unit 1 is an automatic lifting and turning device, delivering metal chips to Unit 2.

Unit 2 shredding metal turnings into small size chips before delivering to Unit 3.

Unit 3 delivering small size metal chips to Unit 4 periodically according to the program setting.

Unit 4 delivering small size metal chips to Briquetting Press Machine Evenly.

Unit 5 Compacting small size metal chips into compact bales.

Unit 6 performs twice filtrations and recovery of the chip liquid during compression.

Unit 1 is an automatic lifting and turning device, delivering metal chips to Unit 2.

Unit 2 shredding metal turnings into small size chips before delivering to Unit 3.

Unit 3 delivering small size metal chips to Unit 4 periodically according to the program setting.

Unit 4 delivering small size metal chips to Briquetting Press Machine Evenly.

Unit 5 Compacting small size metal chips into compact bales.

Unit 6 performs twice filtrations and recovery of the chip liquid during compression.

Details

Bin Lifter and Tipper

1. Suitable for all sizes of chip containers, non-standard sizes can be customized.

2. Hydraulic drive, stable and safety operation,large bearing capacity.

3. The high-performance steel chain conveyor make sure container going up and down stable.

4. Safety door, magnetic lock, power off when door open, monitor window, safety and reliable.

2. Hydraulic drive, stable and safety operation,large bearing capacity.

3. The high-performance steel chain conveyor make sure container going up and down stable.

4. Safety door, magnetic lock, power off when door open, monitor window, safety and reliable.

Swarf Grinding Machine

1. Motor Power: 18.5- 75KW.

2. Single shaft with Screen,can shred long size turnings into short size chips.

3. Equipped with Europe material blades, high wear resistance and long service life.

4. Safety overload protection, intelligent control with touch screen.

2. Single shaft with Screen,can shred long size turnings into short size chips.

3. Equipped with Europe material blades, high wear resistance and long service life.

4. Safety overload protection, intelligent control with touch screen.

Steel Chain Feeding Conveyor

1. The chain plate design (scraper) feed is clean and uniform.

2. Closed, no liquid and chip leakage, ensuring the environment.

3. Prevent corrosion of chip liquid and oil.

2. Closed, no liquid and chip leakage, ensuring the environment.

3. Prevent corrosion of chip liquid and oil.

Centralized Collection Silo

1. Large storage space for more chips.

2. Screw feeding,make sure delivering metal chips to briquetting press achine evenly.

2. Screw feeding,make sure delivering metal chips to briquetting press achine evenly.

Metal Chips Briquetting Press Machine

1. The compression cylinder and the compression cavity are integrated to ensure that the compression center is high and the compression rod does not deviate.

2. The compression cavity and the compression rod are made of imported materials from Europe, which are treated, wear-resistant and have a long service life.

3. The most advanced screw mechanism and feeding mechanism.

4. The UK's most advanced hydraulic system design, intelligent cooling, hydraulic oil constant temperature, system operation is stable.

2. The compression cavity and the compression rod are made of imported materials from Europe, which are treated, wear-resistant and have a long service life.

3. The most advanced screw mechanism and feeding mechanism.

4. The UK's most advanced hydraulic system design, intelligent cooling, hydraulic oil constant temperature, system operation is stable.

Liquid Collection System

1. Simple filtration of the chip liquid/oil.

2. The secondary screen is designed to recover the chip liquid.

3. The chip liquid reaches the liquid level scale and is automatically pumped.

2. The secondary screen is designed to recover the chip liquid.

3. The chip liquid reaches the liquid level scale and is automatically pumped.

Applications

Technical Data Sheet

|

Model

|

BM-1090

|

BM-2013

|

BM-4014

|

BM-6320

|

|

Press Force (tons)

|

100

|

200

|

400

|

630

|

|

Bale Diameter (mm)

|

90

|

130

|

140

|

200

|

|

Motor (kw)

|

11

|

22

|

30

|

135

|

|

System Pressure (mpa)

|

25

|

25

|

25

|

25

|

|

Capacity Aluminum (kg/h)

|

100

|

200

|

500

|

1000

|

|

Capacity Steel (kg/h)

|

200

|

400

|

1000

|

4000

|

|

Operation

|

Automatic

|

Automatic

|

Automatic

|

Automatic

|

Successful Cases

Hot Searches