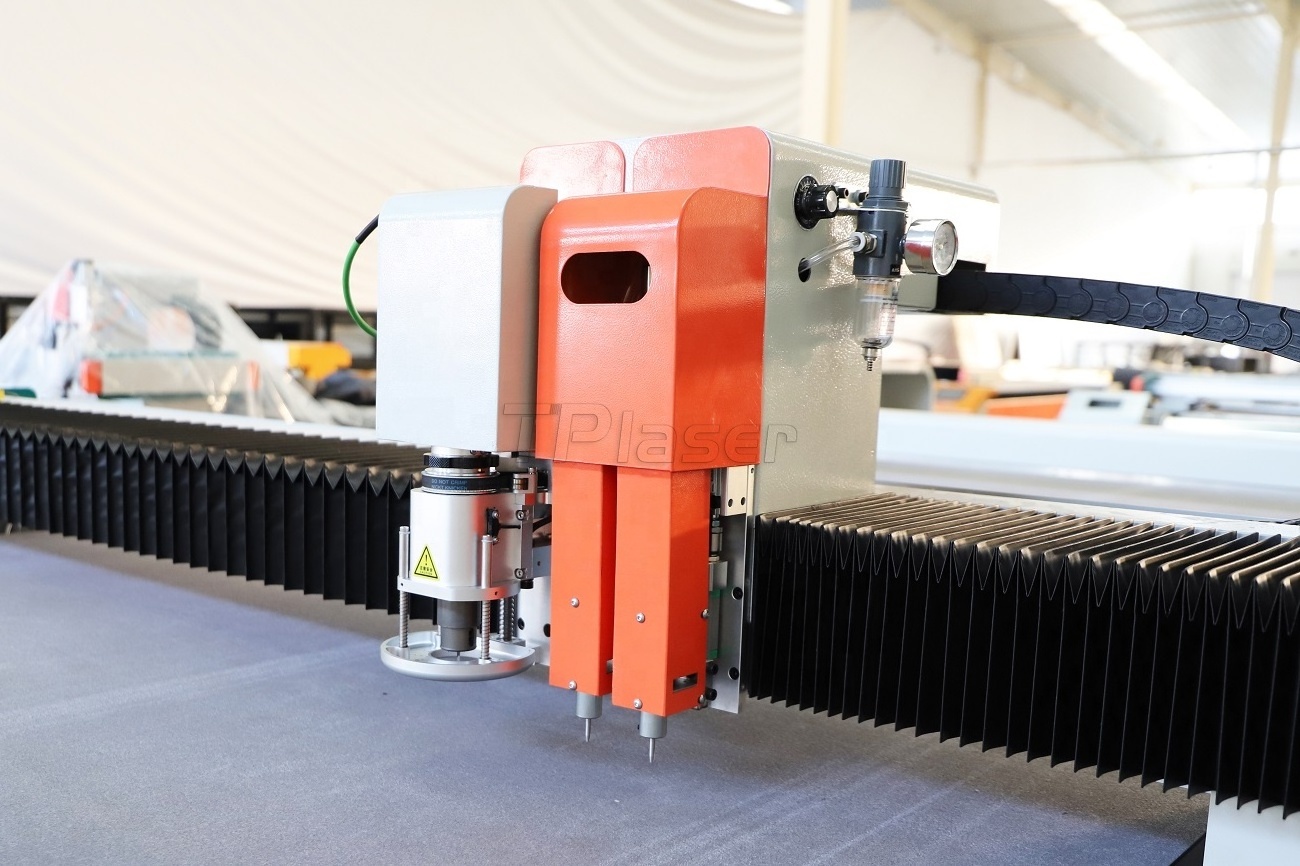

1. Multifunctional tool holder design, cutting, beveling, kiss cutting, punching, scribing, one machine completes multiple processes.

2. The system intelligently optimizes typesetting and cutting, provides better cutting and filling paths, and saves more than 30% of materials.

3. Using Taiwan DELTA servo system, the production efficiency is increased by more than 5 times.

4. TPlaser cardboard cutting machine is fully automatic equipment, automatic loading and unloading, saving labor costs.

5. The aluminum-magnesium alloy adsorption platform is used, which is durable and not deformed.

6. Infrared induction safety device ensures the safety of the operator during the high-speed movement of the machine, and at the same time avoids the loss of cutting materials.

- Product Details

- {{item.text}}

Quick Details

-

Cutting Area:

-

1600*2500mm/3000*1500mm,etc

-

Control Software:

-

TROCEN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TPlaser

-

Weight (KG):

-

1500 KG

-

Mode of Operation:

-

electric

-

Products handled:

-

Cutting

-

Product name:

-

vibrating knife cutting machine

-

Working area:

-

1600mmX2500mm / 1800mmX2500mm / 2000mmmX3000mm...

-

Model:

-

TPV1625

-

Control system:

-

TROCEN LCD touch screen control system

-

Motor and driver:

-

Taiwan Delta Servo Motor

-

Laser head:

-

EOT

-

Table type:

-

Vacuum adsorption pump

-

Transmission system:

-

HIWIN linear guide

-

Cutting speed:

-

200-2000mm/s

-

Support file format:

-

AI,PLT,DXF,CDRetc

Quick Details

-

Laser Type:

-

vibrating knife

-

Cutting Speed:

-

200-2000mm/s

-

Control System Brand:

-

Trocen

-

Cutting Area:

-

1600*2500mm/3000*1500mm,etc

-

Control Software:

-

TROCEN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TPlaser

-

Weight (KG):

-

1500 KG

-

Mode of Operation:

-

electric

-

Products handled:

-

Cutting

-

Product name:

-

vibrating knife cutting machine

-

Working area:

-

1600mmX2500mm / 1800mmX2500mm / 2000mmmX3000mm...

-

Model:

-

TPV1625

-

Control system:

-

TROCEN LCD touch screen control system

-

Motor and driver:

-

Taiwan Delta Servo Motor

-

Laser head:

-

EOT

-

Table type:

-

Vacuum adsorption pump

-

Transmission system:

-

HIWIN linear guide

-

Cutting speed:

-

200-2000mm/s

-

Support file format:

-

AI,PLT,DXF,CDRetc

TPLaser

Vibrating Knife Cutting Machine For

Advertising Industry

Features of

Vibrating Knife CNC Cutting Machine:

|

Brand

|

TPLASER

|

|

Model

|

TPV1625/TPV1825/TPV2025/TPV2030/TPV2040

|

|

Working Area

|

1600x2500mm/1800x2500mm/2000x2500mm/2000x3000mm/2000x4000mm

|

|

|

Vibrating knife full cut, semi-cutting cut, indentation, drawing mark, cursor positioning, camera positioning edge cutting, high

power active round knife |

|

Material fixing method

|

Vacuum partition adsorption

|

|

Servo Motor

|

Taiwan DELTA

|

|

Control System

|

Chinese and English LCD touch screen

|

|

Rack and Pinion

|

Taiwan YYC

|

|

Guide rail Brand

|

Taiwan HIWIN

|

|

Cutting Speed

|

200-2000mm/s

|

|

Cutting Thickness

|

≤50mm Other thicknesses can be customized according to the material

|

|

Support file format

|

AI、PLT、DXF、CDRetc

|

|

Size/Weight

|

3570x2290x1165mm / 1500KG

|

|

Rated voltage

|

380V±10%/220V±10% Optional

|

|

Operating environment

|

Temperature 0-40°C Humidity 20%-80%RH

|

Moduiarized Cutting Tools:

Tool intelligent interchange system.Quickly switch between different props.

Control System:

Independent research and development of multi-axis control system. Simple operation interface and powerful function.

Safety Devices:

Equipped with infrared automatic sensor device, the Safety Device provides a safe working environment.

Power Line+Signal Line:

Bending resistance, high temperature resistance, insulation and anti-static.

Vacuum Alloy Adsorption Table:

The aluminum-magnesium alloy adsorption platform is used, which is durable and not deformed.

Automatic Feeding Device:

Automatic loading and unloading, saving labor costs, processing is more convenient.

Servo Motor:

Ultra-high running accuracy to improve cutting accuracy

Vacuum Pump

Large suction, good adsorption effect, long life.

Optlonal

Applicable

:

Corrugated cardboard, honeycomb cardboard, kraft paper and other packaging boxes, stickers, labels, PP paper, flags, inkjet cloth,light boxes, KT boards, etc.

Corrugated cardboard, honeycomb cardboard, kraft paper and other packaging boxes, stickers, labels, PP paper, flags, inkjet cloth,light boxes, KT boards, etc.

Applicable Industries:

The vibrating knife cutting machine is mainly used in advertising, packaging industry, foam industry; leather, car mat industry; clothing industry.

The vibrating knife cutting machine is mainly used in advertising, packaging industry, foam industry; leather, car mat industry; clothing industry.

1. Strong water resit bottom in the plywood.

2. Laser source (separated plywood case) and spare parts on the laser bed

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

2. Laser source (separated plywood case) and spare parts on the laser bed

3. Corner protect by foam and fixed by protective film.

4. All covered by strong and hard protective film.

5. Vacuum packing Inside steel frame protector.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container , then send to port ship to your country city.

6. Inside steel frame protector.

7. Plywood packing and steel strip outside fixed the box.

8. Finishing packing by normal container , then send to port ship to your country city.

After Service of

Vibrating Knife Cutting Machine

.

1. We will supply the vibrating knife cutting machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

1. We will supply the vibrating knife cutting machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Telephone, Mobile, Whatsapp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

2. You can come to our

vibrating knife cutting machine

factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3~5 days (Recommended)

3. Our engineer will do a door-to-door instruction training service at your local site.

Warranty for V

ibrating knife cutting machine

.

1. 2 years for the whole metal vibrating knife cutting machine , laser device 18 months, chiller 12 months, lens/mirror/nozzle without warranty.

2. Long life-time maintenance, after-sale department will offer 24/7 English online support.

3. Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

4. After the warranty period expired, the buyer only need to pay the actual maintenance cost.

5. Certificate support: CE, SGS.

1. 2 years for the whole metal vibrating knife cutting machine , laser device 18 months, chiller 12 months, lens/mirror/nozzle without warranty.

2. Long life-time maintenance, after-sale department will offer 24/7 English online support.

3. Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

4. After the warranty period expired, the buyer only need to pay the actual maintenance cost.

5. Certificate support: CE, SGS.

Why Choose TPLaser

Vibrating Knife Cutting Machine

1. Adopt advanced 6-axis robot welding equipment to weld the machine bed in all directions, with high precision, superior to 90% of manufacturers in the market.

2. The world famous large gantry drilling machine is used to cut and drill the cnc machine bed to ensure the accuracy of the machine operation.

1. Adopt advanced 6-axis robot welding equipment to weld the machine bed in all directions, with high precision, superior to 90% of manufacturers in the market.

2. The world famous large gantry drilling machine is used to cut and drill the cnc machine bed to ensure the accuracy of the machine operation.

Our Company

Shandong TPLaser Technology Co.,Ltd , Since 2007, it’s a high-tech enterprise producing CNC machine, focusing on the research and development and sales of industrial CNC products, Located in Jinan city (the hometown of CNC Machinery in China) ,has been steadily developing more than 10 years.

Shandong TPLaser Technology Co.,Ltd , Since 2007, it’s a high-tech enterprise producing CNC machine, focusing on the research and development and sales of industrial CNC products, Located in Jinan city (the hometown of CNC Machinery in China) ,has been steadily developing more than 10 years.

TPLaser

has established 3 mode factories with more than 18 automation, high precision processing equipment in China. With a total construction area of 8,500 square meter, it have more than 100 well-trained workers, include 15 domestic and international after-service engineers,60 assembly workers etc.

TPLaser

adheres to the motto of "customer first, service first". we believe in the spirit of enterprise“cooperation, win-win, appreciate and share ", and continue to attract top talents and precision laser technology to join us,

TPLaser

is a leading CNC equipment manufacturer in China and has launched 10 series products with an annual production capacity of 1,120 sets. With advanced CNC technology, perfect quality management system and convenient after-sales service in the network of mainland China and global markets.

If you are interested in any of our products or would like to discuss a custom order,please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Q1. Can i order a custom machine, such as bed appearance、color、use my logo ?

Sure, We accept OEM and ODM as your requirements.

Q2. How long warranty of this pipe Vibrating Knife Cutting Machine ?

The machine laser source lifetime more than 100,000 hours. Two years on parts when get machine, 2 years for free repair. Life-time technical support.

Q3. I am a new operator for this machine, How to operate it ?

When you get v ibrating knife cutting machine , there are English software, User manual and detailed installation & training video in the USB, also our engineer 24 hours technical online support by E-mail, Skype, Live Chat, TeamViewer software. also we supply oversea after-sale service.

Q4. What drawing software will use of Vibrating Knife Cutting Machine ?

This control system compatible with many CAD/CAM software: such as Type3, Artcam, CAS, UG, Autocad, etc. as long as can generate G code, M code is ok.

Q5. What payment terms of this Vibrating Knife Cutting Machine ? and how long can it be completed ?

We support T/T(Telegraphic Transfer), L/C(Letter of Credit), Western Union, Alibaba etc terms. and standard machine we can 15-30 working days can delivery.

Q6. If some problems happened to this machine, what should i do ?

If during warranty, we free change new parts for you; After the warranty period, we provide it with our agent cost for you. and provide technical support for life.

Q7. What certificates your Vibrating Knife Cutting Machine has ? Such as CE, SGS etc

Yes, our company have international certification system certificate: such as CE, SGS, ISO, FA, CO etc.

Sure, We accept OEM and ODM as your requirements.

Q2. How long warranty of this pipe Vibrating Knife Cutting Machine ?

The machine laser source lifetime more than 100,000 hours. Two years on parts when get machine, 2 years for free repair. Life-time technical support.

Q3. I am a new operator for this machine, How to operate it ?

When you get v ibrating knife cutting machine , there are English software, User manual and detailed installation & training video in the USB, also our engineer 24 hours technical online support by E-mail, Skype, Live Chat, TeamViewer software. also we supply oversea after-sale service.

Q4. What drawing software will use of Vibrating Knife Cutting Machine ?

This control system compatible with many CAD/CAM software: such as Type3, Artcam, CAS, UG, Autocad, etc. as long as can generate G code, M code is ok.

Q5. What payment terms of this Vibrating Knife Cutting Machine ? and how long can it be completed ?

We support T/T(Telegraphic Transfer), L/C(Letter of Credit), Western Union, Alibaba etc terms. and standard machine we can 15-30 working days can delivery.

Q6. If some problems happened to this machine, what should i do ?

If during warranty, we free change new parts for you; After the warranty period, we provide it with our agent cost for you. and provide technical support for life.

Q7. What certificates your Vibrating Knife Cutting Machine has ? Such as CE, SGS etc

Yes, our company have international certification system certificate: such as CE, SGS, ISO, FA, CO etc.

Hot Searches