- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

Dustproof soft hand feel inks

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KLB

-

Model Number:

-

PT-0455-2

-

Product name:

-

Soft touch paint for silicone rubber

-

Dust proof:

-

Yes

-

Features:

-

Clear liquid

-

Function:

-

Smooth feeling, soft touch

-

Characters:

-

well Covering power and adhesive power

-

Appearance:

-

Milk White

-

Shelf life:

-

4 months

-

Usual pack:

-

1KG/Bottle

-

Advantage:

-

smooth feeling

-

Raw material:

-

Part A: Silicone resin Part, B: Platinum catalyst.

Quick Details

-

CAS No.:

-

10127-03-4

-

Other Names:

-

Dustproof soft hand feel inks

-

MF:

-

Dustproof soft hand feel inks

-

EINECS No.:

-

Dustproof soft hand feel inks

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KLB

-

Model Number:

-

PT-0455-2

-

Product name:

-

Soft touch paint for silicone rubber

-

Dust proof:

-

Yes

-

Features:

-

Clear liquid

-

Function:

-

Smooth feeling, soft touch

-

Characters:

-

well Covering power and adhesive power

-

Appearance:

-

Milk White

-

Shelf life:

-

4 months

-

Usual pack:

-

1KG/Bottle

-

Advantage:

-

smooth feeling

-

Raw material:

-

Part A: Silicone resin Part, B: Platinum catalyst.

The product is of two component and adopted by low temperature curing technique, It’s mainly used outside coating on the cured silicone rubber surfaces, cured at high temperature (190~220℃).Characterized by smooth feeling, friction resisting, dust proof, well covering strength and adhesion strength. The finished product is like silicone rubber keypads ,adult products , Photocopier , home appliance like remote controllers.

Product specifications:

Typical Data

|

Appearance |

Shallow transparent flowing liquid |

|

Solid Contents |

≥55% |

|

Viscosity |

≥10000mPa.s |

Processing methods:

1. Engage the ready silicone rubber in second cure (190℃-200℃, 8-10minutes ), wash clean the surfaces

2. Add 3% of platinum catalyst into the silicone resin for mixture and dilute with solvent(white gas) six times ,try small quantity first followed by mass input of the solvent when diluting the silicone resin.

3. Please filtrate with 300-400 mesh filter screen for twice before uploading in the spraying gun

4. Leave alone the ready silicone resin for 3-8minutes in the dust-free plant before the spraying process.

Baking method

Baking Condition(190-200℃) 8 – 10 min

|

Processing |

Spray |

|

Spraying Viscosity (Iwata2#Cup,25℃). |

8-10 |

|

Spraying Distance cm |

20-25 |

|

Spray Mouth Diameter mm |

0.8/1.0 |

|

Spraying Pressure mPa |

0.2-0.3 |

|

Baking Condition(190-200℃)min |

8-10 |

Attentions:

1.The opened product should be mixed evenly, while processing the ink , the platinum catalyst should be added before diluting the ink .

2. The spray should be done in a suitable environment ,better in dust-free plant , the temperature is controlled at 20-30℃, humidity at 55~75%.

3. The silicone rubber should be forwarded to second cure above 150℃/10-30 minutes , otherwise will cause poor cure of the paints on the silicone rubber surfaces.

4. The temperature is elevated slowly during the curing stage , Immediate baking after spraying process will result in poor shineness.

5. The mixed silicone resin is to be consumed in 12 hours , sealed low temperature reservation can prolong the activation time.

Applications:

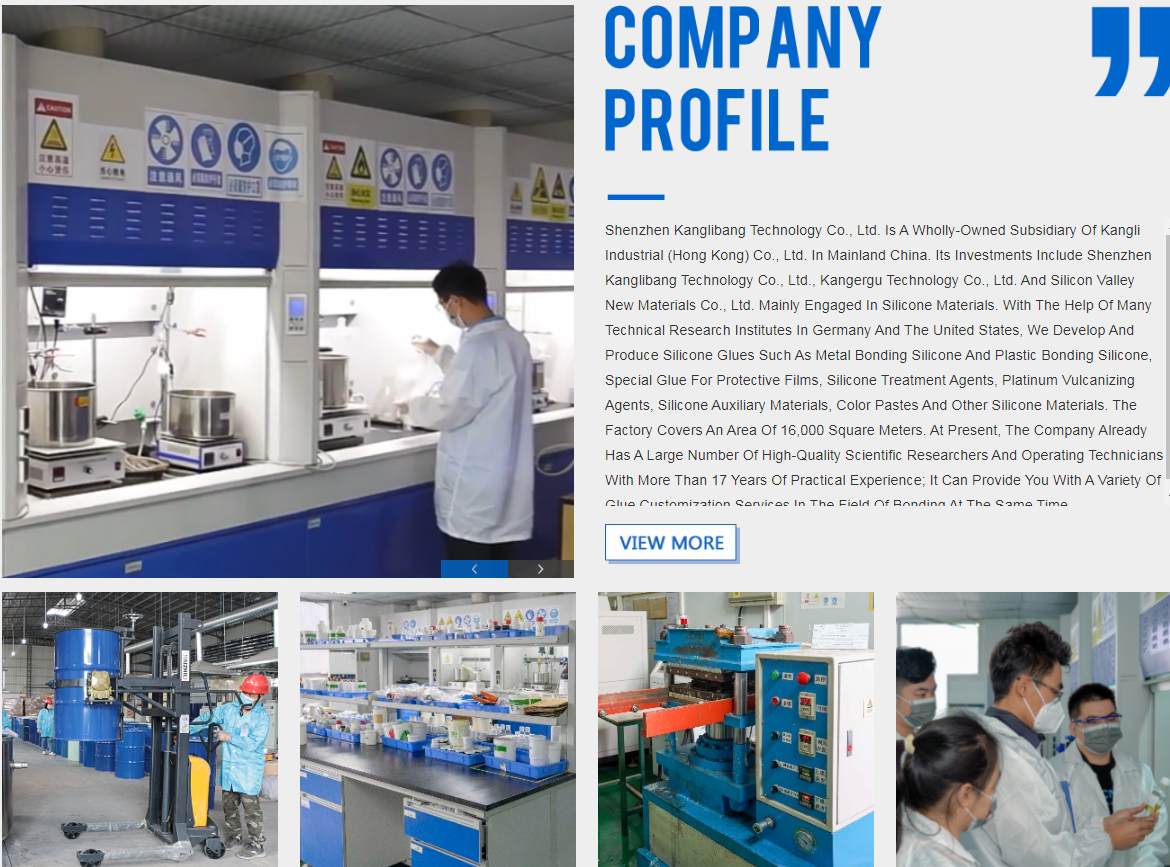

About Us

About Us