- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3 W

-

Dimension(L*W*H):

-

2340x2305x1980

-

Weight:

-

6000 KG

-

Production Capacity:

-

500-1000 Sheets/Min

-

Product name:

-

Non Woven Fabric Soft Cotton Face Tissue Floding Machine

-

Application:

-

Non Woven Soft Cotton Face Tissue Towel Folding Processing

-

Keywords:

-

Soft Cotton Face Tissue Towel Folding Machine

-

Machine Type:

-

Automatic V-shape Fodling Processing Machine

-

Technology:

-

PLC + HMI, VFD System+Pneumatic System, Electric Optical Sensing

-

Material & Structure:

-

55mm Steel Wall Plate Structure

-

Capacity:

-

500-1000Sheets/min

-

Control panel:

-

PLC Touch Screen

-

Related machine:

-

Non Woven Soft Cotton Face Tissue Floding,Cutting,Packing Machine

-

Advantage:

-

Competent to 30-100 Grammage

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SPR

-

Power:

-

3 W

-

Dimension(L*W*H):

-

2340x2305x1980

-

Weight:

-

6000 KG

-

Production Capacity:

-

500-1000 Sheets/Min

-

Product name:

-

Non Woven Fabric Soft Cotton Face Tissue Floding Machine

-

Application:

-

Non Woven Soft Cotton Face Tissue Towel Folding Processing

-

Keywords:

-

Soft Cotton Face Tissue Towel Folding Machine

-

Machine Type:

-

Automatic V-shape Fodling Processing Machine

-

Technology:

-

PLC + HMI, VFD System+Pneumatic System, Electric Optical Sensing

-

Material & Structure:

-

55mm Steel Wall Plate Structure

-

Capacity:

-

500-1000Sheets/min

-

Control panel:

-

PLC Touch Screen

-

Related machine:

-

Non Woven Soft Cotton Face Tissue Floding,Cutting,Packing Machine

-

Advantage:

-

Competent to 30-100 Grammage

PRODUCT DESCRIPTION

SPR TECH

Focus on Disposable Non Woven Fabric Soft Cotton Towel / Tissue Folding, Cutting, Rewinding, Packing Production Processing Machine Equipment Line Solution.

SPR-5T/6T Non-woven Fabric Soft Cotton Towel/Tissue Folding Machine

is suitable for

the V-shape, Interleaf Folding Non-woven Fabric Soft Cotton Towel / Tissue, Face Clean Towel, Soft Cotton Towel, Face Wipe, Tissue, Wash Towel

etc.

Non-woven Flexible Material manufacturing and processing

. It can produce and process Soft Cotton Products in different package by combine with

Non-woven Fabric Soft Cotton Tissue / Towel Cutting Machine, Automatic Soft Cotton Tissue Sheet Separating Machine, Automatic Bag / Box Packing Machine.

SPR-5T/11T Non-woven Fabric Soft Cotton Towel/Tissue Folding Machine

Smooth cutting, Nice trims, Capable for variety of Spunlace Non Woven Fabric Soft Cotton

Cloth such as Pearl Line, EF Line, Plain Line, Anilox, Cleaning Cloth etc. , which from 30-100 grammage.

Cloth such as Pearl Line, EF Line, Plain Line, Anilox, Cleaning Cloth etc. , which from 30-100 grammage.

|

Specifications:

|

|

|

||

|

Model

|

SPR-5T

|

SPR-6T

|

||

|

Max. Width of Raw Material

|

1100MM

|

1250MM

|

||

|

Vacuum Pump System

|

18.5KW

|

18.5KW

|

||

|

Machine power

|

3 KW

|

3KW

|

||

|

Weight

|

5500 KG

|

6000KG

|

||

|

Folding speed

|

500-1000Sheets/min

|

500-1000Sheets/min

|

||

|

Max. Inner Diameters of Roller Core

|

∅76.2mm; other specifications please specify

|

∅76.2mm; other specifications please specify

|

||

|

Max. Diameter of Fabric Roll

|

∅1500mm; other specifications please specify

|

∅1500mm; other specifications please specify

|

||

Key Features

SPR-11T Non-woven Fabric Soft Cotton Towel/Tissue Folding Machine

Key Features and Performance

1) Real-time operation monitoring by using of PLC microcomputer control, HMI, Frequency Conversion-speed Control System, and Rotating Arm Multi-functional Touch Screen displayer.

2) Auto stop Function to avoid the blades damaged by using of Material feeding protection devices.

3) Upper Cutter adopts spiral cutter. It is competent to various non-woven fabric soft cotton towel / Tissue in different grammage and lines. Lower noise. And it can assure the cutting efficiency and avoid the blade damaged and it is easy to bring in the materials and to adjust.

4) Dual VFD (Variable Frequency Drives)system and Independent movable arcual rubber unwinding roller for Front and Rare material feeding to avoid folding surface wrinkled. Better tension control and Better folding results and higher productivity.

5) High speed operation more stable with Wall plate structure; Higher drive accuracy by Timing belts and flat belt drive.

Maintenance free.

6) Separate type material lifting loading structure and dual VFD system to avoid the deformation. It makes the non-woven soft cotton materials loading easier and tension control better and labour-saving.

7) Well match with the automatic cutting machine and packing machine to build a complete non-woven towel / tissue processing machine equipment line.

1) Real-time operation monitoring by using of PLC microcomputer control, HMI, Frequency Conversion-speed Control System, and Rotating Arm Multi-functional Touch Screen displayer.

2) Auto stop Function to avoid the blades damaged by using of Material feeding protection devices.

3) Upper Cutter adopts spiral cutter. It is competent to various non-woven fabric soft cotton towel / Tissue in different grammage and lines. Lower noise. And it can assure the cutting efficiency and avoid the blade damaged and it is easy to bring in the materials and to adjust.

4) Dual VFD (Variable Frequency Drives)system and Independent movable arcual rubber unwinding roller for Front and Rare material feeding to avoid folding surface wrinkled. Better tension control and Better folding results and higher productivity.

5) High speed operation more stable with Wall plate structure; Higher drive accuracy by Timing belts and flat belt drive.

Maintenance free.

6) Separate type material lifting loading structure and dual VFD system to avoid the deformation. It makes the non-woven soft cotton materials loading easier and tension control better and labour-saving.

7) Well match with the automatic cutting machine and packing machine to build a complete non-woven towel / tissue processing machine equipment line.

1, Independent movable arcual rubber unwinding roller

Independent movable arcual rubber unwinding roller for Front and Rare material feeding to

avoid folding surface wrinkled. Better tension control and Better folding results and higher productivity.

avoid folding surface wrinkled. Better tension control and Better folding results and higher productivity.

2, Unique and Efficient Spiral Cutter

Upper Cutter adopts spiral cutter. It is competent to various non-woven fabric soft cotton towel / Tissue in different grammage and lines. Lower noise. And it can assure the cutting efficiency and avoid the blade damaged and it is easy to bring in the materials and to adjust.

3, Material Shortage Warning and Auto-stop Devices

It will warn to reload

and auto-stop when Mast Roll used up. No need the workers to watch and bring the fabric in again. Greatly Improve the

productivity.

and auto-stop when Mast Roll used up. No need the workers to watch and bring the fabric in again. Greatly Improve the

productivity.

4, Synchronized Unwinding System

To coordinate the 2 non-woven soft cotton fabric rolls synchronized. Not to stretch the fabric and not to change the tension of the rolls. It makes

the products natural and soft.

the products natural and soft.

Finished Products

Finished Products, Usage and More ...

Smooth cutting, Nice trims, Capable for variety of Spunlace Non Woven Fabric Soft Cotton Cloth such as Pearl Line, EF Line, Plain Line, Anilox, Cleaning Cloth etc. , which from 30-100 grammage.

Disposable Non woven Soft Cotton Face Clean Tissue Towel, Face Wipe, Facial Tissue Towel

Face cleaning with Dry

and Wet use, Makeup removing, Baby Care, Daily Cleaning, etc

and Wet use, Makeup removing, Baby Care, Daily Cleaning, etc

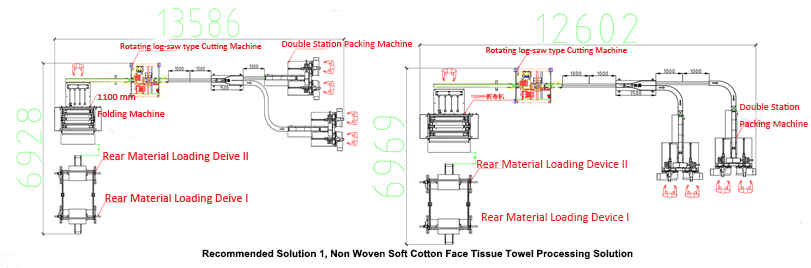

Recommended Soft Cotton Tissue Towel Processing Machine Solution Line:

Recommended Soft Cotton Tissue Towel Processing Solution Line 4

Recommended Soft Cotton Tissue Towel Processing Solution Line 3

Recommended Soft Cotton Tissue Towel Processing Solution Line 3

MORE PRODUCTS

OUR ADVANTAGE

ABOUT US

CERTIFICATE

PACKING & TRANSPORT

Package

:

• Wrapped with plastic film.

• Packed with plywood tray or plywood case, it depends on the machine model.

Delivery Terms & Leading time:

• FOB, FCA, C&F, CIF etc.

• 35~55 dys After downpayment

• Wrapped with plastic film.

• Packed with plywood tray or plywood case, it depends on the machine model.

Delivery Terms & Leading time:

• FOB, FCA, C&F, CIF etc.

• 35~55 dys After downpayment

FAQ

Q1.How does your factory do regarding quality control ?

A1: We control the quality from very beginning.All products process to be detailed. There is also independent QC team who has full time control the production quality.

Q2.Do you offer guarantee for the machine?

A2: Yes, we offer 12 months guarantee for the machine.

Q3.Can you offer the OEM for us?

A3: We welcome you to be OEM client and we are willing to discuss all the details and requirements with you before we issue a formal plan.

Q4. Do you provide finished products sample?

A4: Yes, we can provide you with finished soft cotton tissue towel samples free of charge. But do not pay the freight.

Q5.Why choose us?

A5: Professional and 20 years industrial experience and Technologies accumulation; We have been concentrating on non-woven soft cotton processing machine equipment 11years and it has more than 100 experienced workers and covers a area of nearly 20,000m2. Our equipment are competent to various specs, such as Anilox, EF Line, Pearl Line, Plain different grammage non - woven fabric. International leading non-woven fabric folding, cutting, and packing technology; Customer Oriented From Product plan, Productivity plan,Manufacturing process, and cost control etc. We focus on the Non-woven soft cotton efficiency production line solution. Now, we serve more than 100 manufacturing enterprises.

Q6. Does Your Packing Machine can only pack Soft Cotton Tissue?

No, Besides the Soft Cotton Tissue Towel ,Our Automatic Packing Machine Production Line can also for the Packing Production of the Face Tissues, Face Wash Towel, Face Clean Towel, Sanitary Napkin / Pad, Tissue Paper, Wet Tissue, Wet Wipe, Facial Tissue etc.

Hot Searches