- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

30 KG

-

Product name:

-

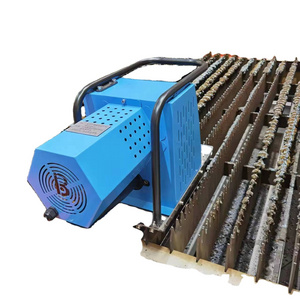

Laser Sword Grid Slag Remover

-

Brand:

-

ADM

-

Keyword:

-

Laser Sword Grid Slag Remover

-

Application:

-

Laser Cuttng

-

Laser type:

-

Fibre Laser

-

Used for:

-

Fiber Laser Marking Cutting Machine

-

MOQ:

-

1set

-

Max Power:

-

30000w

-

Package Type:

-

Plywood Package

-

Voltage:

-

220/380V

Quick Details

-

Place of Origin:

-

China

-

Spare Parts Type:

-

ADM

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

30 KG

-

Product name:

-

Laser Sword Grid Slag Remover

-

Brand:

-

ADM

-

Keyword:

-

Laser Sword Grid Slag Remover

-

Application:

-

Laser Cuttng

-

Laser type:

-

Fibre Laser

-

Used for:

-

Fiber Laser Marking Cutting Machine

-

MOQ:

-

1set

-

Max Power:

-

30000w

-

Package Type:

-

Plywood Package

-

Voltage:

-

220/380V

1.Instructions for safe use of slag remover

1. Keep the workplace tidy: operating machines in a messy workplace is prone to accidental injuries

2. Pay attention to the environment of the workplace: do not work in a dark environment, do not expose the sword gate slag remover to rain and moisture, do not use the machine in an explosive place where there is flammable gas or flammable liquid, because the equipment motor rotates normally and sparks, Sparks may cause fire.

3. The operator should do a good job of self-protection, such as eye protection, ear protection, gloves, and safety shoes.

4. Children should stay away from the workplace, and idlers should not pull the power cord arbitrarily.

5. Take care of the power cord. Do not use the power cord to pull the tool, and do not use the power cord to force the plug down. The power cord should be kept away from heat and oil, and avoid contact with sharp edges.

6. In order to prevent the equipment from starting suddenly, make sure that the switch is in the off position before inserting the plug into the power socket, and remove irrelevant debris such as wrenches andscrewdrivers.

7. Sometimes extension cords are needed for indoor and outdoor operations, and professionally specified extension cords should be used. Must be a three-core power cord, and reliable grounding protection

8. The power must be cut off when the equipment is not in use, before maintenance or when changing tools

9. Keep properly the machines and tools that are not in use temporarily. They should be placed in a dry and high place out of reach of children.

2. Pay attention to the environment of the workplace: do not work in a dark environment, do not expose the sword gate slag remover to rain and moisture, do not use the machine in an explosive place where there is flammable gas or flammable liquid, because the equipment motor rotates normally and sparks, Sparks may cause fire.

3. The operator should do a good job of self-protection, such as eye protection, ear protection, gloves, and safety shoes.

4. Children should stay away from the workplace, and idlers should not pull the power cord arbitrarily.

5. Take care of the power cord. Do not use the power cord to pull the tool, and do not use the power cord to force the plug down. The power cord should be kept away from heat and oil, and avoid contact with sharp edges.

6. In order to prevent the equipment from starting suddenly, make sure that the switch is in the off position before inserting the plug into the power socket, and remove irrelevant debris such as wrenches andscrewdrivers.

7. Sometimes extension cords are needed for indoor and outdoor operations, and professionally specified extension cords should be used. Must be a three-core power cord, and reliable grounding protection

8. The power must be cut off when the equipment is not in use, before maintenance or when changing tools

9. Keep properly the machines and tools that are not in use temporarily. They should be placed in a dry and high place out of reach of children.

Hot Searches