- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SANJIN BRAND

-

Voltage:

-

380V 50hz or Customized

-

Dimension(L*W*H):

-

2300*1100*2000mm

-

Motor Power (Kw):

-

55+3+1.5+1.5+0.37kw

-

Power (kW):

-

61.37kw

-

Weight (KG):

-

4700 KG

-

Marketing Type:

-

Hot Product 2021

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Product name:

-

Pet fish feed pellet machine

-

Keywords:

-

biomass pellets making machine

-

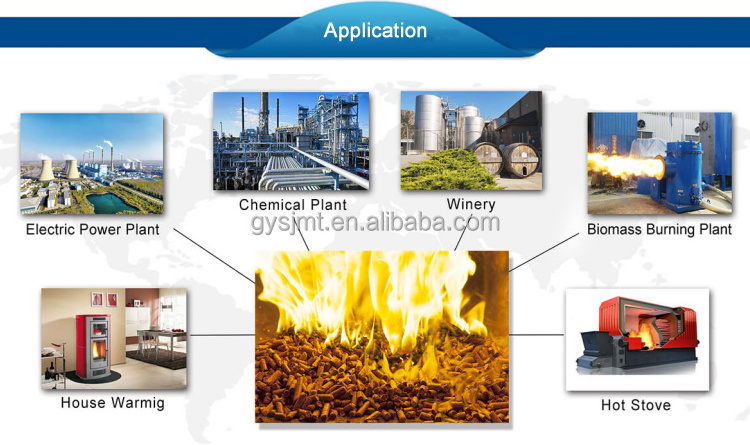

Application:

-

Make Biomass Pellets

-

Usage:

-

Making Wood Pellets Animal Feed Pellets

-

Capacity:

-

800-1000kg/h

-

Color:

-

Clients' Requirement

-

Spare parts:

-

Ring Die+ Rollers

-

Ideal moisture:

-

Biomass Pellet 10-15%

-

Pellet size:

-

4-12mm Diameter

Quick Details

-

Pellet Diameter (mm):

-

4 - 12

-

Output (kg/h):

-

800 - 1000 kg/h

-

Place of Origin:

-

Henan, China

-

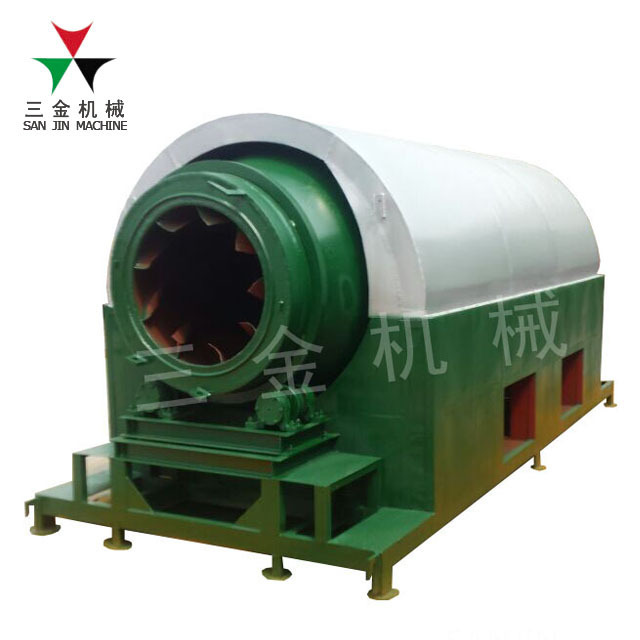

Brand Name:

-

SANJIN BRAND

-

Voltage:

-

380V 50hz or Customized

-

Dimension(L*W*H):

-

2300*1100*2000mm

-

Motor Power (Kw):

-

55+3+1.5+1.5+0.37kw

-

Power (kW):

-

61.37kw

-

Weight (KG):

-

4700 KG

-

Marketing Type:

-

Hot Product 2021

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Product name:

-

Pet fish feed pellet machine

-

Keywords:

-

biomass pellets making machine

-

Application:

-

Make Biomass Pellets

-

Usage:

-

Making Wood Pellets Animal Feed Pellets

-

Capacity:

-

800-1000kg/h

-

Color:

-

Clients' Requirement

-

Spare parts:

-

Ring Die+ Rollers

-

Ideal moisture:

-

Biomass Pellet 10-15%

-

Pellet size:

-

4-12mm Diameter

Related products

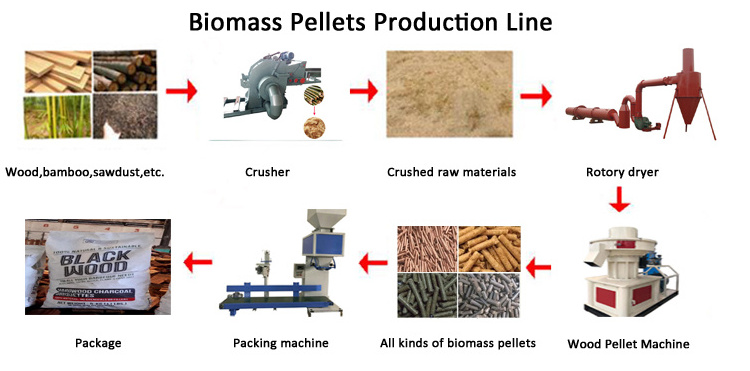

Product Description

Professional Manufacturer Hops Alfalfa Sawdust Wood Biomass Pellet Making Machine

Introduction:

Wood machine pellet is a kind of molding equipment which can compresses agricultural and forestry biomass(disperse finely divided,non-shaped)into a rod-shaped and granular shape under the action of a certain temperature and pressure.Biomass granules can use biomass and other wastes such as wood chips, straw, rice husks and bark as raw materials, and solidify them into high-density granule fuels through pretreatment and processing. It is an ideal fuel to replace kerosene. It can not only save energy but also reduce soot emissions, but also economic and social benefits. It is an efficient and clean renewable energysource.

Features:

*1. The mold is vertical and vertical feeding; the mold is stationary, the pressure roller rotates; the material is centrifuged, the material distribution is uniform;

*2. 360 degree output high efficiency and energy saving; automatic lubrication system high pressure filtration, clean and smooth; independent frequency conversion, to ensure pellet molding.

*3. The pelletized fuel after molding has a large specific gravity, is small in volume and resistant to combustion, and is convenient for storage and transportation. The volume after molding is 1/30 of the volume of the raw material, the specific gravity is 10-15 times of the raw material, and the calorific value can reach 3400-6000 kcal.

*4. Material and Finished Production:

wood machine pellet is suitable for all kinds of crop straw, wood chips, bamboo chips, rice husks, branches, bark, peanut melon shell, bagasse, Chinese medicine residue, sage and other raw materials, water content 10-30 % can be processed.

*1. The mold is vertical and vertical feeding; the mold is stationary, the pressure roller rotates; the material is centrifuged, the material distribution is uniform;

*2. 360 degree output high efficiency and energy saving; automatic lubrication system high pressure filtration, clean and smooth; independent frequency conversion, to ensure pellet molding.

*3. The pelletized fuel after molding has a large specific gravity, is small in volume and resistant to combustion, and is convenient for storage and transportation. The volume after molding is 1/30 of the volume of the raw material, the specific gravity is 10-15 times of the raw material, and the calorific value can reach 3400-6000 kcal.

*4. Material and Finished Production:

wood machine pellet is suitable for all kinds of crop straw, wood chips, bamboo chips, rice husks, branches, bark, peanut melon shell, bagasse, Chinese medicine residue, sage and other raw materials, water content 10-30 % can be processed.

Working Principle:

*1 The wood machine pellet uses the principle of interaction between the pressing force between the annular die and the pressing wheel and the frictional force of the die hole to make the material form.

*2 There is no need to add any additives and binders during the processing of the materials. The wood materials have softening characteristics. When the temperature reaches a certain value, the softening and bonding strength are enhanced under a certain pressure to make the molecular clusters dislocation, deformation and extension. The adjacent biomass particles are recombined and pressed into shape.

*1 The wood machine pellet uses the principle of interaction between the pressing force between the annular die and the pressing wheel and the frictional force of the die hole to make the material form.

*2 There is no need to add any additives and binders during the processing of the materials. The wood materials have softening characteristics. When the temperature reaches a certain value, the softening and bonding strength are enhanced under a certain pressure to make the molecular clusters dislocation, deformation and extension. The adjacent biomass particles are recombined and pressed into shape.

Wood pellet Machine Use Raw Material:

1. Wood waste, scobs, branch, palm tree, sugarcane residue, sawdust, medical slag, hay, discarded edible fungus.

2. Bean stalk, wheat stalk, corn stalk, cotton stalks, sunflower stalks, mustard stalk, rice stalks, coffee husk, cotton shell, peanut shell, rice shell, coconut shell.

3. Livestock and poultry's waste, tea waste, tea waste, forestry wastes, forestry wastes, wood chips and many other organic waste resources.

1. Wood waste, scobs, branch, palm tree, sugarcane residue, sawdust, medical slag, hay, discarded edible fungus.

2. Bean stalk, wheat stalk, corn stalk, cotton stalks, sunflower stalks, mustard stalk, rice stalks, coffee husk, cotton shell, peanut shell, rice shell, coconut shell.

3. Livestock and poultry's waste, tea waste, tea waste, forestry wastes, forestry wastes, wood chips and many other organic waste resources.

Specification

|

Model

|

HY-450

|

HY-560

|

HY-600

|

HY-700

|

||||

|

Power

|

55+3+1.5+1.5+0.37kw

|

90+3+1.5+1.5+0.37kw

|

110+3+1.5+1.5+0.37kw

|

132+3+1.5+1.5+0.37kw

|

||||

|

Inner Dia of ring die

|

450mm

|

550mm

|

600mm

|

700mm

|

||||

|

Capacity

|

800-1000kg/h

|

1500-2000kg/h

|

2000-2500kg/h

|

2500-3000kg/h

|

||||

|

Dimension

|

2200*1100*2000mm

|

2350*1300*2300mm

|

2600*1300*2400mm

|

2900*1300*2400mm

|

||||

|

Weight

|

4.7t

|

5.8t

|

6.9t

|

9t

|

||||

|

Diameter of Pellets (MM):

6-12mm

|

|

|

|

|

||||

|

Temperature of Pellets (°C):

80-100

|

|

|

|

|

||||

|

Moisture of Feed Materials (%):

15-20

|

|

|

|

|

||||

Details Images

Final product

Packing & Delivery

Hot Searches