Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China, Jiangsu, China

-

Brand Name:

-

qiangsheng

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

25000*1200*1800MM

-

Power (kW):

-

75

-

Weight:

-

30000 KG

-

Name:

-

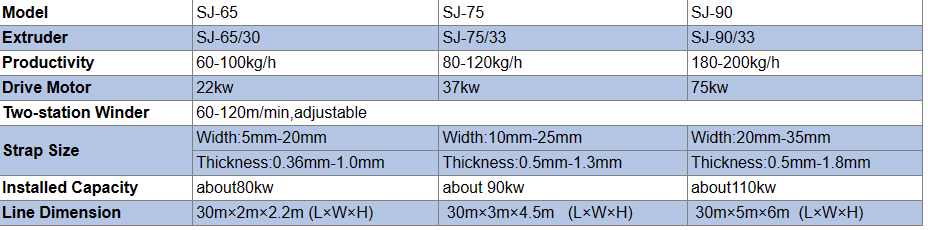

PP/PET Strap Band Packing Belt Production Line

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Temperature Control:

-

Omron Brand

-

Control:

-

Siemens PLC+Touch Screen

-

model:

-

pvc Pipe

-

Raw material:

-

pvc

-

After Warranty Service:

-

Video technical support, Online support, Spare parts...

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

156:1

-

Screw Speed (rpm):

-

80 rpm

-

Place of Origin:

-

Jiangsu, China, Jiangsu, China

-

Brand Name:

-

qiangsheng

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

25000*1200*1800MM

-

Power (kW):

-

75

-

Weight:

-

30000 KG

-

Name:

-

PP/PET Strap Band Packing Belt Production Line

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Temperature Control:

-

Omron Brand

-

Control:

-

Siemens PLC+Touch Screen

-

model:

-

pvc Pipe

-

Raw material:

-

pvc

-

After Warranty Service:

-

Video technical support, Online support, Spare parts...

Video Description

Product Description

PVC Shutter Windows Production Line

Production of raw materials can be used to produce packaging belts with recycled materials or mixed new materials. It is also possible to add calcium carbonate according to customer conditions to reduce production costs, increase product profit, and market competitiveness.

The screw and the cylinder of SJ-PP type automatic or manual PP plastic strapping band making machine adopt excellent quality alloy steel done nitrogen treatment, which leads to long using life, good abrasion resistant and high output of extruding. This machine has advantages of auto temperature control, economical power consumption, high output and easy operation. It use PE powder, which is mainly Ι&ΙΙ grade recycing material, as it is main material. It does not need to fry or mix the raw material, but

use it directly, during the process of producting the granules; it uses mineral powder instead of expensive master batch to produce auto strapping band, which improves the quality of the products and reduce the production cost. The machine has printing device. Double lines, four lins, six lines, eight lines.

The screw and the cylinder of SJ-PP type automatic or manual PP plastic strapping band making machine adopt excellent quality alloy steel done nitrogen treatment, which leads to long using life, good abrasion resistant and high output of extruding. This machine has advantages of auto temperature control, economical power consumption, high output and easy operation. It use PE powder, which is mainly Ι&ΙΙ grade recycing material, as it is main material. It does not need to fry or mix the raw material, but

use it directly, during the process of producting the granules; it uses mineral powder instead of expensive master batch to produce auto strapping band, which improves the quality of the products and reduce the production cost. The machine has printing device. Double lines, four lins, six lines, eight lines.

Features of PP PET Packing Belts Production Line:

1. Production of raw materials can be used to produce packaging belts with recycled materials or mixed new materials. It is also possible to add calcium carbonate according to customer conditions to reduce production costs, increase product profit, and market competitiveness.

2. The output is high, and the finished line speed can reach 260m/min.

3. The appearance of the whole machine has been optimized, beautiful and high-grade, durable and durable.

4. High-precision die parts make the product forming quality stable, width and thickness fluctuations are far less than the

national standard; unique network changing device greatly reduces the network changing time.

5. High-precision high-quality screw, using well-known brand, unique parameter design, with the advantages of large extrusion, good plasticization, high hardness and high wear resistance.

6. Configure special hardened gear reducer, high speed wear and long service life.

7. Unique design of correcting device to control product skewness.

8. Unique oven loop heating system, the internal reciprocating winding method, fully utilizing thermal energy to greatly reduce power loss.

9. Unique stretching process, with good rigidity and stable width.

10. Unique loop cooling system, multiple sets of guide roller, which makes the strap cooling and shrinking more complete, the product is more stable and the size is more accurate.

11. Five-roll traction system, the traction is stable, the equipment runs smoothly, the failure rate is reduced, and the

maintenance cost is reduced by 60%.

12. High-precision special embossing and pressing device, adjustable pressure, clear and beautiful embossing, improved product quality, comparable to Europe, America, Japan and South Korea.

13. Constant force winding system, unique design parameters, in line with high output, excellent tape winding effect, flat and beautiful section.

14. Wheel and shaft parts are made of high-strength alloy steel. The gears are processed by carburizing, quenching and grinding, and the equipment failure rate is reduced by 60%.

15. Using computer programming control system, automatic memory strapping production specification data, easy to operate, easy to debug.

16. The PP production line has four belts, and the stable production volume reaches 5-6 tons per day! The latest product PP production line has six belts, which is the first in the industry.

17. Optional no-stop automatic screen changer! Maximize benefits.

Product details show

|

|

|

|

|

|

The company's main products(Click Text)

Our Company

Zhangjiagang City Qiangsheng Plastic Machinery

Zhangjiagang City Qiangsheng Plastic Machinery Co.,Ltd.is located in Jingfeng town Sanxing Industry park, Zhangjiagang City. It is one of the professional manufacturers of plastic machinery.The enterprise pays attention to technological improvement, actively introduces domestic and foreign advanced technology,improves old products and develops new ones. Its main products:double-screw extruder, single-screw extruder, sets of extruding production lines and auxiliary equipment, such as, PE, PP, PVC, PP-R plastic pipe production line,plastic profile production line, plastic granutating line, plastic recycling line and others. The products are sold well twenty-nine provinces, cities and autonomous regions and are exexported to Russia, Africa, Middle East, east Europe, South America and Southeast Asia. "quality first,customer first“is the aim of our company. We sincerely welcome new and old customers to our enterprise and talk about business with us.

Packaging and Shipping

FAQ

Q1:What about the payment terms?

A1:Always 30% down payment as deposit,70% balance pay before shipping.

Q2:What about the payment way?

A2:TT,L/C at sight or Made in China trade assurance.

Q3:If you will send engineer coming to our factory to install and test the machines?

A3:Yes,Every set of machine we will send professional engineer to your factory and help installation and test the machines for

you.

Q4:If you have CE,SGS,ISO certificate?

A4:Yes,except these,if you also need other certificates,we also can help to apply.

Q5:If we buy your machines, can you offer us wear-out spare pats?

A5:Yes,We provide our high quality machine 1 years' guarantee,and we will also offer you 1 years wear-out spare parts for free.

Once your machines broken or doesn't work within 1 years and you can't solve it, firstly, we will try to help you to find problems

from your words description by phone or other communication tools. Secondly, if the phone solutions still not work, our engineers

will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

Q6:What is the voltage?

A6 380V 50hz 3 phase or any other voltage according to client's requirement.

A1:Always 30% down payment as deposit,70% balance pay before shipping.

Q2:What about the payment way?

A2:TT,L/C at sight or Made in China trade assurance.

Q3:If you will send engineer coming to our factory to install and test the machines?

A3:Yes,Every set of machine we will send professional engineer to your factory and help installation and test the machines for

you.

Q4:If you have CE,SGS,ISO certificate?

A4:Yes,except these,if you also need other certificates,we also can help to apply.

Q5:If we buy your machines, can you offer us wear-out spare pats?

A5:Yes,We provide our high quality machine 1 years' guarantee,and we will also offer you 1 years wear-out spare parts for free.

Once your machines broken or doesn't work within 1 years and you can't solve it, firstly, we will try to help you to find problems

from your words description by phone or other communication tools. Secondly, if the phone solutions still not work, our engineers

will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

Q6:What is the voltage?

A6 380V 50hz 3 phase or any other voltage according to client's requirement.

Hot Searches