- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V/440V

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

1500 kg

-

Raw material:

-

Fly Ash Cement Sand Concrete

-

Block Type:

-

Hollow Concrete Brick Machine

-

Color:

-

Customer's Demand

-

Molding cycle:

-

24s

-

Advantage:

-

High Efficiency

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

Cement,crushed stone,sand

-

Production Capacity (Pieces/8 hours):

-

5760 pcs/8hours, 12000 pcs/8hours, Other

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V/440V

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

1500 kg

-

Raw material:

-

Fly Ash Cement Sand Concrete

-

Block Type:

-

Hollow Concrete Brick Machine

-

Color:

-

Customer's Demand

-

Molding cycle:

-

24s

-

Advantage:

-

High Efficiency

Product Overview

Semi Automatic QT4-24 Concrete Fly Ash Hollow Solid Block Make Machine Brick Making Machinery Factory Price

GRZ4-24 Cement Concrete Brick Making Machine, an efficient and intelligent brick-making powerhouse. With automated production, high efficiency, and versatility for various concrete brick types. Sturdy and durable, environmentally friendly and energy-efficient. Choose

GRZ4-24

for intelligent efficiency, helping you build the future.

FEATURES AT A GLANCE

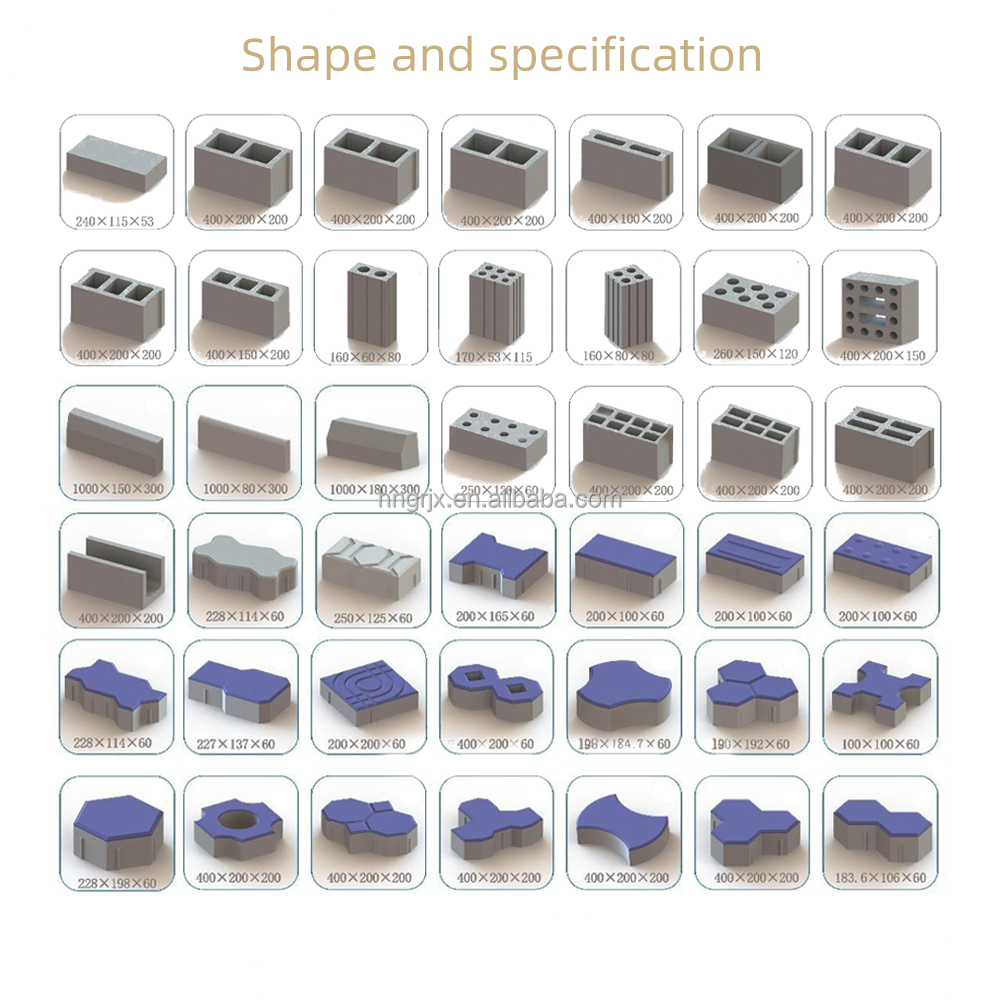

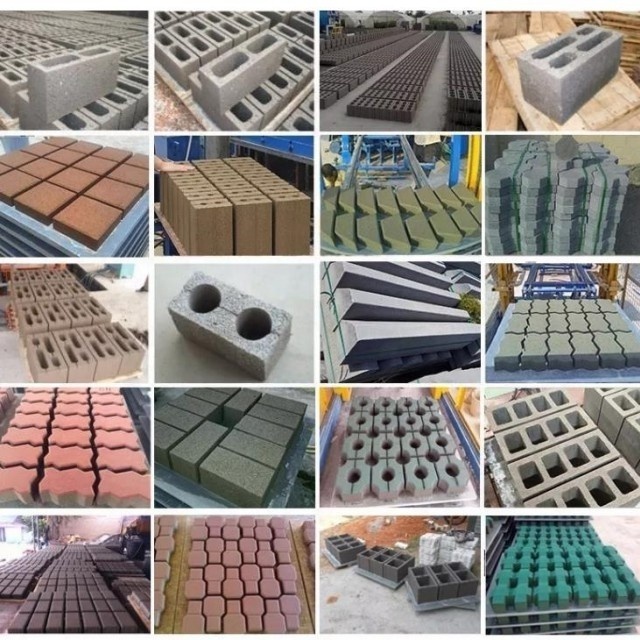

We support the customization of the size and pattern of the mechanical bricks

GRZ4-2B

cement concrete brick making machine leading efficient intelligent brick making technology. Our brick making machines use advanced intelligent technology to provide you with excellent brick manufacturing solutions.

GRZ4-2B

not only has efficient production capacity, but also performs well in the manufacture of cement concrete bricks.

Please inform us of your thoughts on the size and pattern when you contact us again, because we have corresponding molds.

Details Images

Features

Manual assisted control:

The operator is involved, but the control is easier than manual brick making.

Production efficiency:

Compared with manual, the production efficiency is improved, and each brick making cycle is faster.

Relatively low cost:

Compared to fully automatic equipment, the price is more economical, suitable for small and medium-sized manufacturers.

Easy to operate:

the operator training is short and easy to use.

Suitable for small-scale production:

For small-scale production, it is a practical and economical choice.

Flexibility:

Adapt to different types and sizes of brick production needs.

Efficient use of resources:

More efficient use of raw materials and less waste.

Customizability:

Some models are customizable and can be adjusted according to customer needs.

|

name of parameter

|

detailed parameters

|

|

Dimensions

|

2000*2100*1850mm

|

|

Molding cycle

|

24 seconds/time

|

|

Total power

|

14KW

|

|

Weight

|

1.8/tons

|

|

Production (8 hours)

|

about 3,500 hollow bricks, about 35,000 standard bricks

|

|

Die size

|

850*550mm

|

|

name of parameter

|

detailed parameters

|

|

Output capacity

|

350L

|

|

Weight

|

400KG

|

|

Dimension

|

1400X1300X1250mm

|

|

Power

|

7.5kw

|

|

name of parameter

|

detailed parameters

|

|

Motor power

|

0.75kw

|

|

Length

|

3200mm

|

|

Weight

|

300kg

|

|

Dimension

|

3300*800*700mm

|

Paking & Delivery

All the wear out spare parts are packed by plastic films and wooden boxes.

FCL: Shipping by standard exporting container.

LCL: Poly wood case.

Why Choose Us

We have sufficient supply and rich field experience

Pre-Sale Service:

1.We offer various pre-sales services to help customers plan their investments and manufacturing with reduced costs.

2.After assessing customers' goods and sizes, we recommend the most suitable machines.

3.We suggest machines based on customers' usage and budget.

In-Sale Service:

1.We provide step-by-step manufacturing photos for customers to review. Packing and

shipping are arranged according to customers' needs.

2.Machines are tested, and videos are provided for customer inspection.

After-Sale Service:

1.We guarantee machine quality for one year.

2.Free training and timely technical support are provided to address any questions or concerns.

2.After assessing customers' goods and sizes, we recommend the most suitable machines.

3.We suggest machines based on customers' usage and budget.

In-Sale Service:

1.We provide step-by-step manufacturing photos for customers to review. Packing and

shipping are arranged according to customers' needs.

2.Machines are tested, and videos are provided for customer inspection.

After-Sale Service:

1.We guarantee machine quality for one year.

2.Free training and timely technical support are provided to address any questions or concerns.

We have sufficient and high quality machines and have rich field experience

Hot Searches