- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Power:

-

3.5kW

-

Dimension(L*W*H):

-

1200width x 1500 height x 2920 depth

-

Weight (KG):

-

1000

-

Filters:

-

12pcs(polyester)

-

Fan motor power:

-

5.5Kw

-

Fan motor:

-

1pc

Quick Details

-

Machine Type:

-

powder coating booth, Spray Booths

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

COLO

-

Voltage:

-

380V/220V

-

Power:

-

3.5kW

-

Dimension(L*W*H):

-

1200width x 1500 height x 2920 depth

-

Weight (KG):

-

1000

-

Filters:

-

12pcs(polyester)

-

Fan motor power:

-

5.5Kw

-

Fan motor:

-

1pc

Product Description

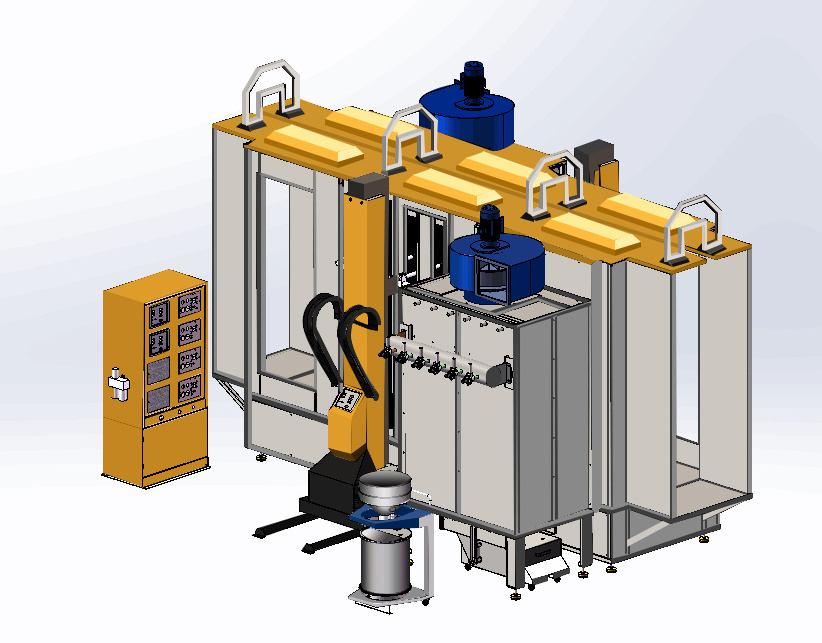

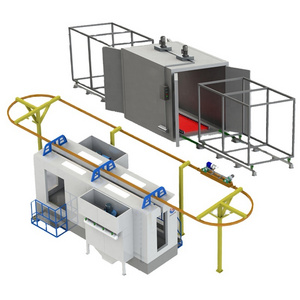

Automatic Powder Coating Spray Booth System

Our automatic powder coating booths are designed to increase your productivity, product quality and profitability in automatic powder application lines

All our powder coating booths are configured with high efficiency powder recovery system ensures great powder utilization that saves your cost.

This is the COLO 2020 Hot Sale

Automatic Powder Coating Booth

for Production lIne.

COLO Automatic powder coating Booth Features

1. Parts are pass thru the spray booth,hang on the conveyor system

2. With 2 stations for automatic powder coating reciprocator, as well as 2 openning stations for staff for manual coating.

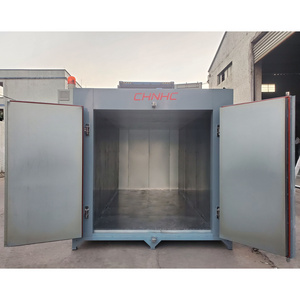

3. Booth material is duable powder-coated steel, durable, anti-static

1. Parts are pass thru the spray booth,hang on the conveyor system

2. With 2 stations for automatic powder coating reciprocator, as well as 2 openning stations for staff for manual coating.

3. Booth material is duable powder-coated steel, durable, anti-static

4. Widely applicated

for mass production

in automatic powder coating line with single color.

5,

Made with premium components and shipping factory-direct, high quality powder booth with good price!

6, Size and special configurations can be customizes by COLO 10 yrs+ engineers

Technical Data

|

Model

|

COLO-0825

|

|

Booth Type

|

drive-thru

|

|

Inner size (mm)

|

800 width x 2000 height x 4000 depth

|

|

Overall Dimension (mm)

|

1200 width x 2580 height x5000 depth

|

|

Weight

|

1100kg

|

|

Power Supply

|

5.5kw

|

|

Filters

|

12pcs (polyester)

|

|

Filter hang type

|

easy for change

|

|

Filter cleaning system

|

Pneumatic

|

|

12 month

|

12 month

|

Detailed Pictures

Powder Collector Modules

There are Cartridge modules attached directly to the powder booth at both sides, which are compact and requires less factory space..

Catridge Filters

Our cartridge filters are made of high precision filters, which ensures 100% separation of powders from air. Only dust free air exhausted.

PLC Control

Filter cleaning, fan working, all controlled by PLC, giving you easy and reliable operation process.

Fan

A powerful centrifugal fan sucks the air from the cabin, dragging the remaining powder paint from the application

towards primary filters.

towards primary filters.

Pulse jet cleaning

Filter Cleaning are through pulse-jet controlled by soleniod valves. This pulse-jet cleaing extent filter's life.

Powder Collector Hopper

The filtered powder is then discharged into a hopper trolley beneath the unit which can be manually rolled away for fully emptying, or connected with powder feed center for automatic recycling.

Application

Automatic Powder Coating Booth Applications - Customer Case in Latvia

Perfectly synchronized with conveyor, reciprocator, automatic powder coating guns, centralized powder feed center. Ideal for automatic application of powder coating aluminum profiles, furniture products, metal doors, fence, iron gates, automotive parts, etc.

We have professional technical team design powder coating booths and systems as customer required!

Related Products

Hot Searches