- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

8000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

110-480V Customized

-

Power:

-

52KW

-

Product Type:

-

snack

-

Name:

-

Food Snacks Production Line

-

After-sales Service Provided:

-

Field Installation Commissioning Training

-

Usage:

-

Food Industry Equipment

-

Type:

-

Fully Automatic

-

Material:

-

304 Stainless Steel

-

Raw material:

-

potatoes,eggplant,etc

-

Function:

-

Multifunctional

-

Capacity:

-

100-2000KG/H

-

Suitable for:

-

Food Processing Plants

-

Package:

-

Wooden Case

Quick Details

-

Machinery Capacity:

-

100-500kg/h

-

Brand Name:

-

LINYANG

-

Dimension(L*W*H):

-

17*1.5*2.2M

-

Weight:

-

8000 KG

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

110-480V Customized

-

Power:

-

52KW

-

Product Type:

-

snack

-

Name:

-

Food Snacks Production Line

-

After-sales Service Provided:

-

Field Installation Commissioning Training

-

Usage:

-

Food Industry Equipment

-

Type:

-

Fully Automatic

-

Material:

-

304 Stainless Steel

-

Raw material:

-

potatoes,eggplant,etc

-

Function:

-

Multifunctional

-

Capacity:

-

100-2000KG/H

-

Suitable for:

-

Food Processing Plants

-

Package:

-

Wooden Case

Product Description

Parameter

|

No.

|

Name

|

Size

|

Heating method

|

|

1

|

Conveyor

|

2500*600*1500mm

|

electric

|

|

2

|

Washing and peeling machine

|

2300*1000*1600mm

|

electric

|

|

3

|

Picking line

|

4000*800*750mm

|

electric

|

|

4.

|

conveyor

|

2500*600*135mm

|

electric

|

|

5

|

Slicer

|

1070*560*900mm

|

electric

|

|

6

|

Rinsing machine

|

2500*1000*900mm

|

electric

|

|

7

|

Blanching machine

|

5500*1000*1350mm

|

electric/diesel /gas or others

|

|

8

|

Air-cooled dehydrator

|

4000*1000*1150mm

|

electric

|

|

9

|

Frying machine

|

5000*1000*2100mm

|

electric/diesel /gas or others

|

|

10

|

Vibration screen

|

2000*800*900mm

|

electric

|

|

11

|

Air-cooled deoling

|

4000*1000*1150mm

|

electric

|

|

12

|

IQF

|

9600*4000*2900mm

|

Freon

|

|

13

|

Conveyor

|

2000*800*1000mm

|

electric

|

|

14

|

Packing machine 520

|

5218*3610*3650mm

|

electric

|

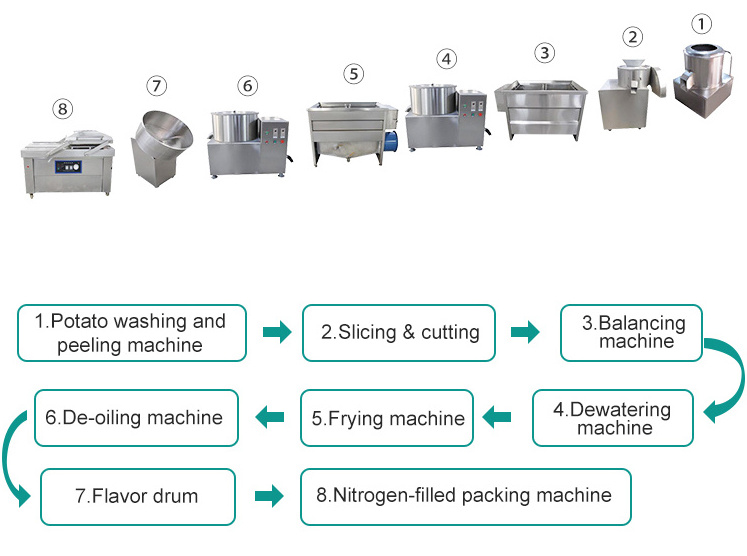

Operation Process

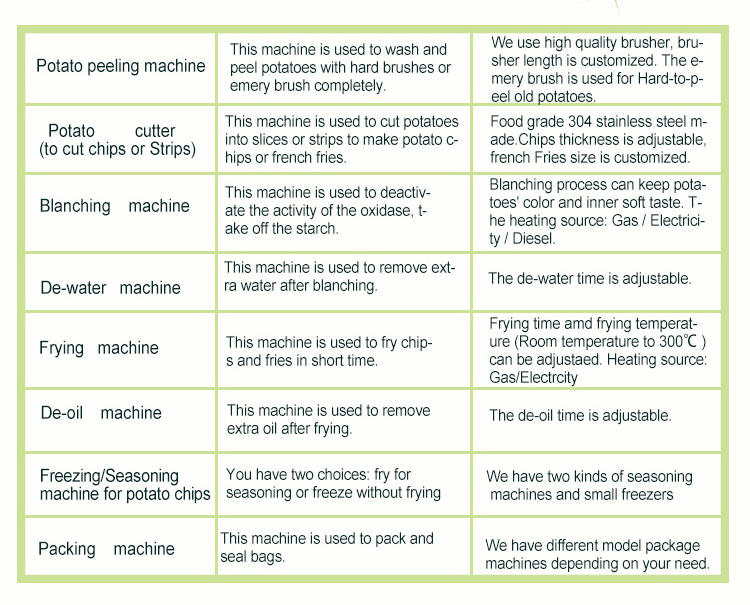

Equipment and components

1. Hoister with water spray

It is used to preclean potato,soften the potato skin, then hoist potatoes into washing and peeling machine.

2. Washing and peeling machine

This machine is used to peeling potatoes with hard brush and emery brush; Uneven and corrugated brush can peel the potatoes completely.

3. Inspecting table

This machine is used to pick out potato eyes and dark parts on potatoes by manually. There will be waste material holes and unpeeled potatoes return system.

4. Hoister with water spray

This machine is used to preclean potato, soften the potato skin, then hoist potatoes into washing and peeling machine.

5. Potato cutter

This machine is used to cut potato into sticks, french fries quality depends on fries length and shape, so cutting machine is very important.

6. Rinsing machine

This machine used to washing potato starch and protect potato from oxidation, keep its original color.

7. Blanching machine

This machine is used to deactivate the activity of the oxidase, take off the starch, separate out the reducing sugar, also after blanching,it will get inner soft taste of french fries.

8. Vibrating machine to de-water

Used to remove water.Also have many holes at the end of machine to leak out small part and waste part potato.

9. Electric dryer

Remove water, drying fries

10. Continuous frying machine

This machine is used to unified fry sticks in short time.

11. Vibrating de-oil machine

This machine is used to de-oil with the vibrating.

12. Cooling line

Use fan to blow off the water on stick surface, then deliver sticks into the freezer.

13. Conveyor

Used between cooling line and quick-freezing machine.

14. Fluidized-type freezer

It is used to quick freezing the french fries in short time, fries center temperature at -18 ℃, Can the maximum keep the original flavor and product quality.

15. Conveyor

Used between quick-freezing machine and packing machine.

16. Automatic weighing and packing machine

It is used to pack the french fries automatically, including bucket Elevator.

1. Hoister with water spray

It is used to preclean potato,soften the potato skin, then hoist potatoes into washing and peeling machine.

2. Washing and peeling machine

This machine is used to peeling potatoes with hard brush and emery brush; Uneven and corrugated brush can peel the potatoes completely.

3. Inspecting table

This machine is used to pick out potato eyes and dark parts on potatoes by manually. There will be waste material holes and unpeeled potatoes return system.

4. Hoister with water spray

This machine is used to preclean potato, soften the potato skin, then hoist potatoes into washing and peeling machine.

5. Potato cutter

This machine is used to cut potato into sticks, french fries quality depends on fries length and shape, so cutting machine is very important.

6. Rinsing machine

This machine used to washing potato starch and protect potato from oxidation, keep its original color.

7. Blanching machine

This machine is used to deactivate the activity of the oxidase, take off the starch, separate out the reducing sugar, also after blanching,it will get inner soft taste of french fries.

8. Vibrating machine to de-water

Used to remove water.Also have many holes at the end of machine to leak out small part and waste part potato.

9. Electric dryer

Remove water, drying fries

10. Continuous frying machine

This machine is used to unified fry sticks in short time.

11. Vibrating de-oil machine

This machine is used to de-oil with the vibrating.

12. Cooling line

Use fan to blow off the water on stick surface, then deliver sticks into the freezer.

13. Conveyor

Used between cooling line and quick-freezing machine.

14. Fluidized-type freezer

It is used to quick freezing the french fries in short time, fries center temperature at -18 ℃, Can the maximum keep the original flavor and product quality.

15. Conveyor

Used between quick-freezing machine and packing machine.

16. Automatic weighing and packing machine

It is used to pack the french fries automatically, including bucket Elevator.

Operation

Packing And Delivery

Hot Searches