Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

1200 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WingsPlastic

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

8000mm 2000mm 2500mm

-

Power (kW):

-

80

-

Weight:

-

10000 KG

-

Motor:

-

China Top Brand

-

Inverter:

-

Delta Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

Siemens Contactor

-

switch:

-

CHNT

-

Marketing Type:

-

New Product 2020

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

65 mm

-

Screw Speed (rpm):

-

1200 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WingsPlastic

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

8000mm 2000mm 2500mm

-

Power (kW):

-

80

-

Weight:

-

10000 KG

-

Motor:

-

China Top Brand

-

Inverter:

-

Delta Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

Siemens Contactor

-

switch:

-

CHNT

-

Marketing Type:

-

New Product 2020

Product Description

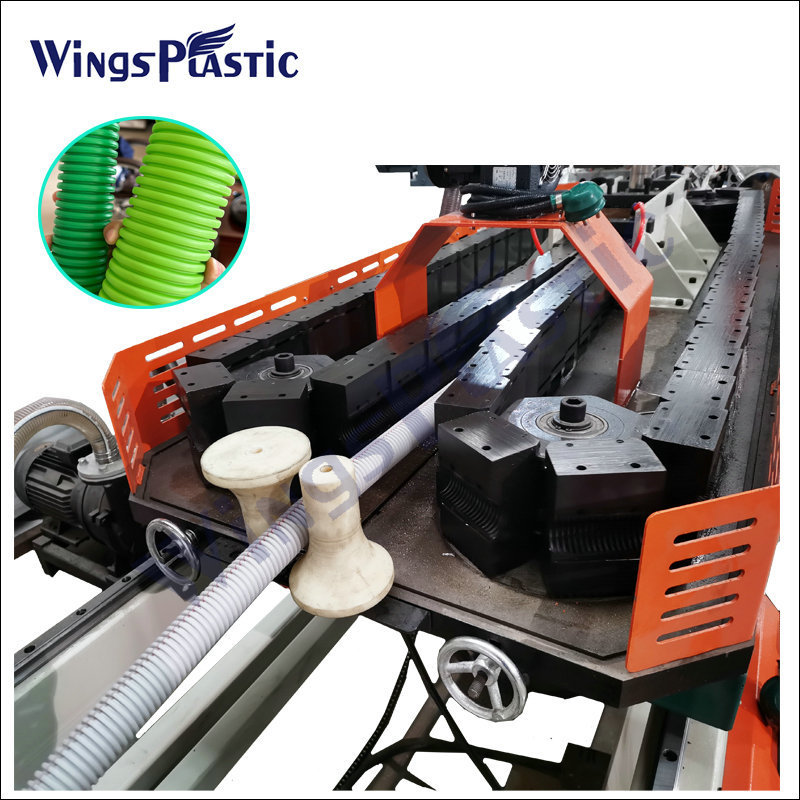

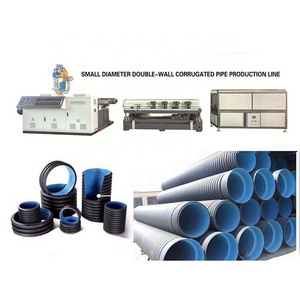

Automatic Plastic 40-110mm DWC Pipe making machine hdpe double wall corrugated pipe machine production line

1.

DWC Pipe making machine

2.

hdpe double wall corrugated pipe machine

3.

hdpe double wall corrugated pipe production line

Qingdao Wings Plastic Technology Co., Ltd. is a professional manufacturer of plastic pipe machine, located in Jiaozhou City, Qingdao, one of the concentrated areas of plastic machinery industry in China.

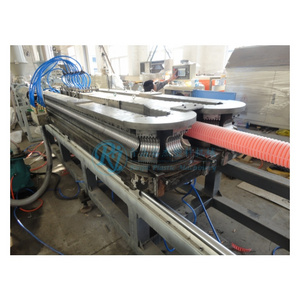

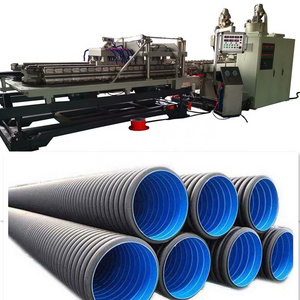

Double-wall corrugated pipe production line adopts the direct extrusion molding process, high efficiency production , reliable quality. Due to its excellent wall structure design, the pipe have lightest weight , and the pipe cost greatly reduced, a large number alternatives of traditional concrete pipe and cast iron pipe.

Qingdao Wings Plastic Technology Co., LTD., specializing in the production of HDPE double-wall corrugated pipe production line,PVC double-wall corrugated pipe production line.

Equipment operation is stable, automatic production, saving labor, efficient extrusion.

Extruder:

1, Double extruder, advanced screw design, assure the high speed extrusion of double-wall corrugated pipe;

2, A temperature control system, reliable guarantee to produce high quality PVC double-wall corrugated pipe and HDPE double-wall corrugated pipe.

Double-wall corrugated pipe production line adopts the direct extrusion molding process, high efficiency production , reliable quality. Due to its excellent wall structure design, the pipe have lightest weight , and the pipe cost greatly reduced, a large number alternatives of traditional concrete pipe and cast iron pipe.

Qingdao Wings Plastic Technology Co., LTD., specializing in the production of HDPE double-wall corrugated pipe production line,PVC double-wall corrugated pipe production line.

Equipment operation is stable, automatic production, saving labor, efficient extrusion.

Extruder:

1, Double extruder, advanced screw design, assure the high speed extrusion of double-wall corrugated pipe;

2, A temperature control system, reliable guarantee to produce high quality PVC double-wall corrugated pipe and HDPE double-wall corrugated pipe.

Specification

|

Suitable Pipe Diameter

|

Model Extruder

|

Output

|

Motor Power

|

Production Speed

|

|

40-110mm

|

SJ 65/33 and SJ 50/30

|

180kg/h

|

30kw and 15kw

|

1-6m/min

|

|

75-200mm

|

SJ 75/33 and SJ 65/33

|

400-450kg/h

|

75kw and 45kw

|

1-8m/min

|

Details Images

Single Screw Extruder

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality PIPE extrusion.

Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barrel>940, the surface of screw is chromeplated Feeding bush with water cooling system

Extrusion Die

Material :40Cr , the surface of die is chromeplated, anti-corrosive

Two layer with aluminum cooling sleeve

High Speed Forming Machine

Gear driven system with high precision modules and tracks. The track is water cooling system, it could meets 4-6m/min working speed.It is added water cooling and fan cooling two system.

Mould Block

Materials of moulds block:40Cr

The moulds are made by CNC system, it is high precison and long service life.

We could add the vacuum system for option

Automatic Coiler

No of wheel: two wheel or one wheel according customer request.Useing

torque motor

system, it is automatic adjustment of winding speed.

Control Box

Temperature controller: OMRON

Contactor and replay: SIEMENS

Inverter: ABB or Delta Character

High precise temperature control.

Configurable alarm strategy.

All of the production data can be displayed electrical panel.

Very easy operation.

Running stability

Final Product & Application

Advantage of Double Corrugated Pipe Machine

1) Extremely strong resistance to chemical corrosion and erosion.2) Good flexibility and strong impact resistance

3) Cold resistance and aging resistance. The connection is simple, safe and reliable.

4) Light weight and convenient construction.

5)Strong wear resistance. The service life is more than 50 years, and it is maintenance-free during the service life.

6) Superior drainage performance. It is hygienic and can be recycled and used.

If you want to know more about Plastic Pipe Extrusion Line, inquiry us now!

1) Extremely strong resistance to chemical corrosion and erosion.2) Good flexibility and strong impact resistance

3) Cold resistance and aging resistance. The connection is simple, safe and reliable.

4) Light weight and convenient construction.

5)Strong wear resistance. The service life is more than 50 years, and it is maintenance-free during the service life.

6) Superior drainage performance. It is hygienic and can be recycled and used.

If you want to know more about Plastic Pipe Extrusion Line, inquiry us now!

Company Introduction

Qingdao Wings Plastic Technology Co, Ltd, is the professional manufacturer and exporter of the plastic extrusion line, our company passed the ISO 9001- 2008 international quality system certification and all products have acquired CE certificate of EU. For years, the company has leading technology for plastic extrusion system in the world market, such as high speed corrugated pipe extrusion line, plastic PET PP strap production line, plastic pipe extrusion line, plastic sheet / floor mat extrusion line. Our extrusion line has high technology content and practicability, it is popular in domestic market and exported to more than twenty countries including: USA, India, Brazil, Turkey, Pakistan, Egypt, Ukraine,Namibia,Paraguay etc.

Company focus on the plastic extrusion line manufacturing over years, top quality top service.

We focus on the quality control, and hope to build a long time business rlationship with customers.

Our Service

Service Before Sale

1. 24 hours online. Your inquiry will be quick reply by email. Also can go through all questions with you

by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction,details pictures and working video to show machine

Service On Sale

1. Test every machine and inspect the machine seriously.

2.Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is

ok.

3.Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free. If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your

airport, Or logistic to the warehouse which you request. We will tell you the tracking number after delivery.

Service After Sale

1. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to

help you solve the problem, or dispatch worker to your factory. All the symbols on the equipment should be in English. Seller

is responsible to provide general layout plan, electric plan, installation direction, and manual book in English to Buyer on

time.

Wings will provide long-term technical guide.

by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction,details pictures and working video to show machine

Service On Sale

1. Test every machine and inspect the machine seriously.

2.Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is

ok.

3.Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free. If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your

airport, Or logistic to the warehouse which you request. We will tell you the tracking number after delivery.

Service After Sale

1. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to

help you solve the problem, or dispatch worker to your factory. All the symbols on the equipment should be in English. Seller

is responsible to provide general layout plan, electric plan, installation direction, and manual book in English to Buyer on

time.

Wings will provide long-term technical guide.

Recommend Products

Hot Searches