- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

180 mm

-

Dimension:

-

3200*1600*2600

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ALDM

-

Weight (KG):

-

8000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

CNC Press Brake

-

Application:

-

Sheet Metal Bending

-

Voltage:

-

220V/380V/415V/440V/customized

-

Electronics:

-

Schneider, France

-

Main power:

-

Siemens, Germany

-

Gasket ring:

-

VALQUA, Japan

-

Valve:

-

Rexroth, Germany

-

Material:

-

Metal Steel Sheet

-

After-sales Service Provided:

-

Video technical support, Spare parts, Field maintenance repair service

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

180 mm

-

Dimension:

-

3200*1600*2600

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ALDM

-

Weight (KG):

-

8000

-

Motor Power (kw):

-

7.5 kw

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

CNC Press Brake

-

Application:

-

Sheet Metal Bending

-

Voltage:

-

220V/380V/415V/440V/customized

-

Electronics:

-

Schneider, France

-

Main power:

-

Siemens, Germany

-

Gasket ring:

-

VALQUA, Japan

-

Valve:

-

Rexroth, Germany

-

Material:

-

Metal Steel Sheet

-

After-sales Service Provided:

-

Video technical support, Spare parts, Field maintenance repair service

Main feature

1. The frame is steel structure, left and right vertical plate, table and pressure plate welded into a unitary structure, after

welding to eliminate internal stress by tempering, exceptional rigidity, high stability.

bending machine cnc press brake bending machine mini press brake machine

2. Important parts of the frame, sliders, etc. are used ANSYS finite element analysis software to ensure machine reliability.

bending machine cnc press brake bending machine mini press brake machine

3. Hydraulic drive, cylinder on both end of machine, disposed on the slider to drive it work directly.

press brake hydraulic press rake cnc press brake

4. Torsion axis synchronization for slide synchronous mechanism.

5. Adopt a mechanical stopper mechanism, stable and reliable.

6. Back Gauge size and slide stroke controlled by CNC system, back gauge with high precision ball screw, stable operation and precise positioning.

7. The CNC system adopts frequency conversion control technology, with multi-step programming function, simple and easy to operate.

8. Inclined wedge deflection on the compensation mechanism, in order to guarantee access to high bending accuracy

9. Safety barrier device all around the machinery, electrical cabinets equipped with Open door cut-off function, emergency stop button around front and back, protective cover foot switch to ensure safe working.

Techical parameters

|

Item

|

Optional model

|

Manufacturer

|

|

CNC system

|

DA-41s/E200P/E300P

|

Delem/ESA

|

|

Hydraulic system

|

Pressure valve

|

HOERBIGER/BOSCH

|

|

Number of backgauge shafts

|

Single axis / dual axis

|

ALDM

|

|

Oil pump

|

Single-stage oil pump

|

ALDM

|

|

Main power system

|

AC motor

|

Simens/NW

|

|

Front support

|

Simple fixed type / single track movable type / double track movable type

|

ALDM

|

|

Security

|

Side (guardrail) + rear (guardrail) / side (guardrail + light curtain protection) + rear (guardrail)

|

ALDM

|

|

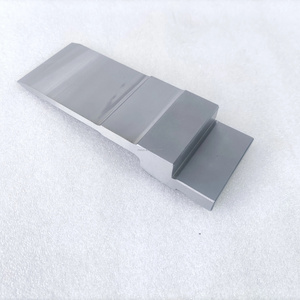

Deflection compensation

|

Electrical deflection compensation/manual mechanical deflection compensation

|

ALDM

|

|

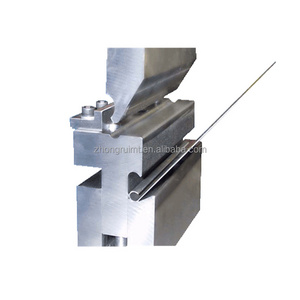

Mold clamping

|

Hand pressure type upper mold clamping

|

ALDM

|

|

Electric

|

Schneider Relay

|

Schneider

|

|

Foot switch

|

Korea Kaikun vertical switch

|

Kaikun

|

|

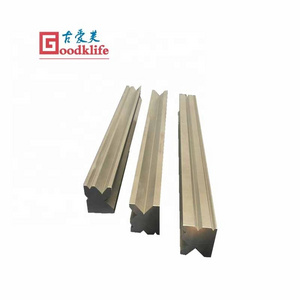

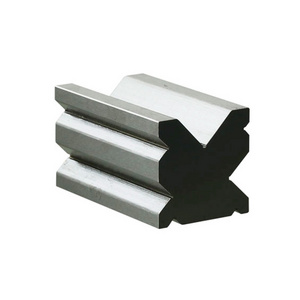

Die

|

Multi-V die/Dual V co-core die

|

ALDM

|

Details Images

Back

Electrical box

Motor

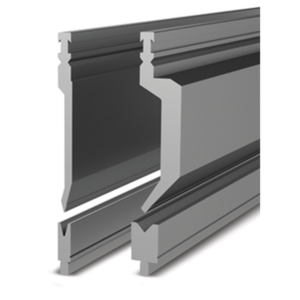

Mould

Foot switch

CNC system (optional)

Our services

Pre-sales Service

1. Inquiry and consulting support

2. Sample testing support

3. Recommend the most suitable machine according to customer's purpose

4. Factory visiting welcomed

After-sales Service

1. Training how to install the machine

2. Training how to use the machine

3. Warranty 1 year

4. Engineers available to service machinery oversea

Hot Searches