- Product Details

- {{item.text}}

Quick Details

-

Model:

-

DT 125

-

Certification:

-

ACCEPTABLE

Quick Details

-

Displacement (ml):

-

125CC

-

Place of Origin:

-

China

-

Warranty:

-

1 YEAR

-

Model:

-

DT 125

-

Certification:

-

ACCEPTABLE

Company Introduction

Founded in 1998, Shandong Zhenting Jinggong Piston Co.,Ltd. is an excellent large-scale private enterprise specializing in the production of piston, piston pin and circlip for automobile, motorcycle, general gasoline engine, diesel engine, compressor and air conditioning engine, with an annual production capacity of 70 million kits. The production and sales are far ahead in the industry.

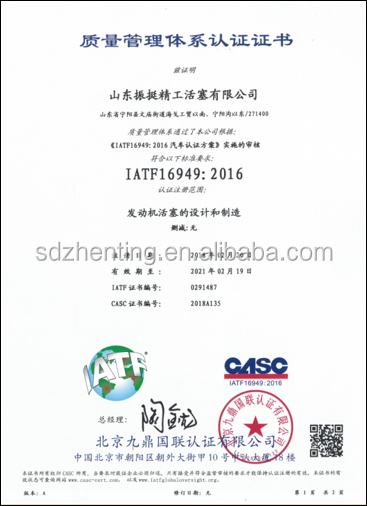

Certifications

Workshop Overview

👆 Mould Workshop

Using the advanced mold producing machine(CNC), we can produce all kinds of casting, die-casting and forging molds. We have the advantage of high mold production efficiency and stable quality.

Our molds are 100% self-made.

👆 Melting Workshop

Our combined smelting furnace is consist of smelting furnace and alloy holding furnace.

- Highly increase the Aluminium smelting efficiency.

- Using natural gas as fuel, r

ealize environmental protection and energy saving.

- Speed up the circulation time of Aluminium liquid, shorten the storage time in the furnace, which make hydrogen content reduced and further improve the casting quality.

👆 Casting Workshop

To meet the industry needs, with advanced foundry production equipment, we can produce all kinds of casting, die casting, forging pistons for automobile, motorcycle, general gasoline engine, diesel engine and various internal combustion engine, air compressor and etc.. The gravity casting and die casting machines are increased to 140 sets and 3 sets respectively. Now the annual production capacity is more than 70,000,000 pcs.

👆 Continuous Heat Treatment Furnace

opens to the workpiece totally emerges into the water ≤ 20 seconds), which can guarantee the quenching quality effectively and increase the uniformity of product. The product hardness of the same batch does not exceed 3 HRB units, which can fully guarantee the blank quality.

👆 Machining Workshop

The piston machining lines are a semi-automatic and flexible piston production lines, which can produce various kinds of piston with valve pocket, pressure reducing chamber, special pin hole and complex peripheral structure, with design annual production capacity of 70,000,000pcs. They have the characteristics of wide processing range, short production preparation cycle, high production efficiency and etc..

👆 Surface Treatment Workshop

Using automatic surface treatment production line, the factory has the characteristics such as high efficiency, stable quality, environmental protection, with design annual production capacity of 30 million.

👆 Piston Pin Workshop

With advanced production equipment, we realized the automatic processing, including machining, heat treatment, packing. Run on two shift and the capacity of piston pin workshop is 70 million per year, with wide processing range, high production efficiency, high product precision.

👆 Inspection Workshop

100% visual inspection for important dimensions.

👆 Warehouse and Delivery

4000㎡of finished parts storage warehouse ensures 10 days of safety stock for regular products. Self-owned transport fleet guarantees the efficiency and quality of product transportation.

Expo

Global Marketing

We do the promotion of globalized market, to be the global supplier of customers!

Hot Searches