- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DOYAN

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

160X130X110CM

-

Weight:

-

360 kg

-

Marketing Type:

-

Hot Product 2024

-

PLC Brand:

-

no

-

Product name:

-

ROLLING PLATFORM DIE CUTTING MACHINE

-

Function:

-

Cutting Sheet

-

After-sales Service Provided:

-

Online Support

-

Application:

-

Printing Company

-

Cutting materials:

-

Multiple Materials

-

Name:

-

Flatbed Die Cutting Machine

-

Keyword:

-

Multi Sheet Cutter

Quick Details

-

Type:

-

cutting machine

-

Production Capacity:

-

50 m/min

-

Max. workable width:

-

1.2MM

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DOYAN

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

160X130X110CM

-

Weight:

-

360 kg

-

Marketing Type:

-

Hot Product 2024

-

PLC Brand:

-

no

-

Product name:

-

ROLLING PLATFORM DIE CUTTING MACHINE

-

Function:

-

Cutting Sheet

-

After-sales Service Provided:

-

Online Support

-

Application:

-

Printing Company

-

Cutting materials:

-

Multiple Materials

-

Name:

-

Flatbed Die Cutting Machine

-

Keyword:

-

Multi Sheet Cutter

Product Paramenters

|

cutting speed

|

1-800mm/s

|

|

Cutting thickness

|

<1.2mm

|

|

cutting pressure

|

1000g

|

|

cutting material

|

Crystal label Heat press

|

|

cutting method

|

Physical semi-cutting and full-cutting dry glue magnetic stickers, etc. (plates need to be equipped with vibration rigs)

|

|

Pen Type/Knife Type

|

Double pole structure

|

|

a fixed way

|

Double-sided tape paste/vacuum adsorption

|

|

drive mode

|

High speed servo drive

|

|

mechanical resolution

|

0.05mm

|

|

transmission interface

|

USB, U disk offline, network port (WIFI optional)

|

|

Compatible software format

|

SignMaster/Ai/AutoCAD/Coraldraw, compatible cutting plotter output software

|

|

screen size

|

touch display

|

|

Working voltage/power

|

AC 220V±10%/50Hz

|

|

cutting area

|

600mm*900mm (segmented automatic material pulling)

|

|

Machine size

|

1460mm*1300mm*1000mm

|

|

Package Size

|

1600mm*1300mm*1100mm

|

|

Machine net weight

|

220kg

|

|

Machine gross weight

|

240kg

|

Manufacturing Technique

1、Using servo motors to drive imported linear guide rail transmission mode, combined with intelligent Al algorithms, to bring you a better operating experience for your irregular cutting.

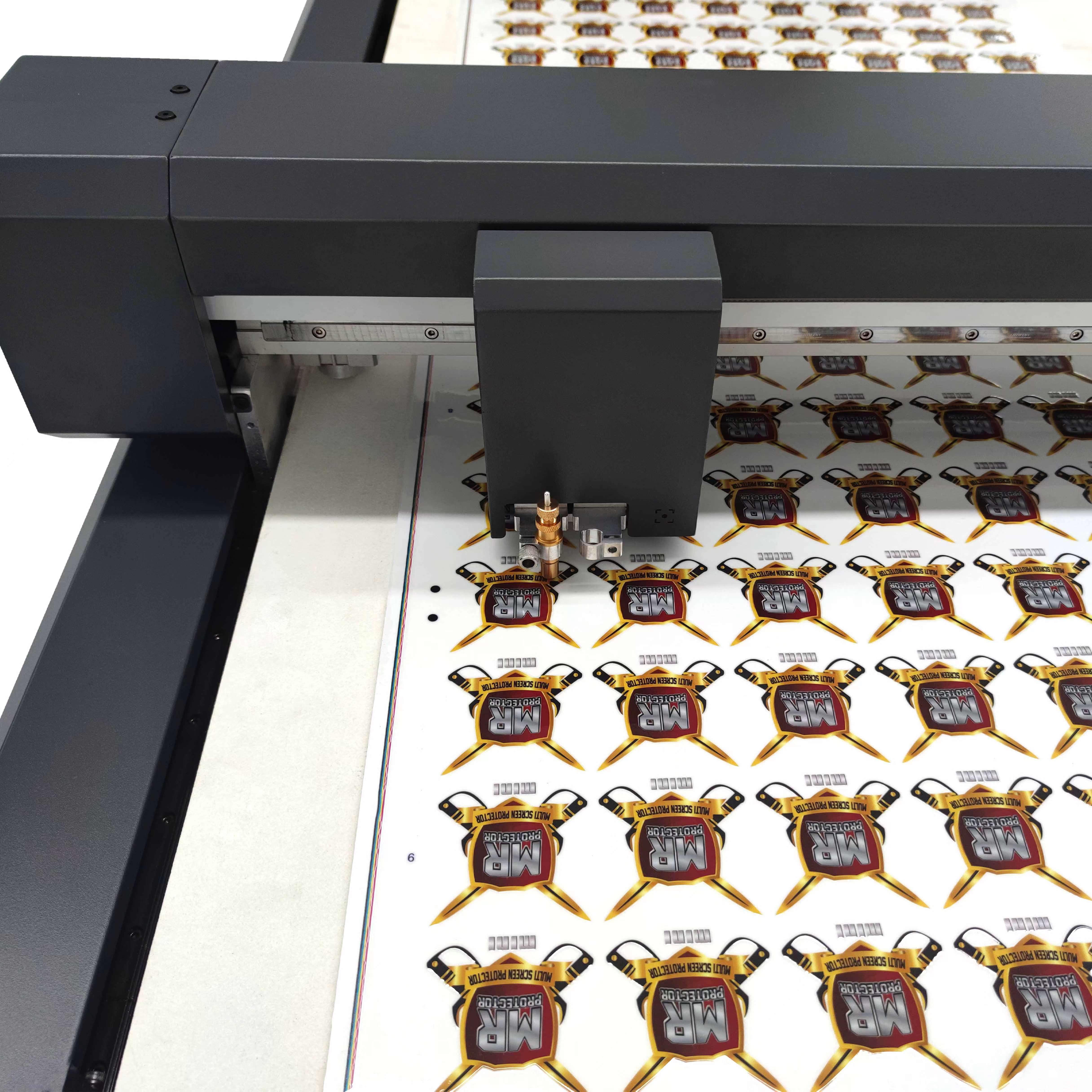

2、The camera positioning real-time tracking system is precise and sensitive, quickly identifying and cutting various complex irregular patterns.

3、Automatic contour extraction and edge cutting no longer require professional computer operators, greatly reducing the entry threshold for equipment operators.

4、The patented platform structure design, multi zone vacuum adsorption design, low noise, strong suction, helps you easily control the adsorption of small samples.

5、LCD high-definition touch screen makes the field of view more beautiful and the control more convenient.

6、Comprehensively expand various transmission interfaces, USB, USB flash drives, Ethernet ports, and create efficient cutting experiences for different scenarios.

7、The automatic feeding device easily achieves perfect docking for long format cutting processing, and with the support of the camera positioning and real-time tracking system, achieves precise and stable contour cutting.

8、The independently developed advanced high-end multi axis high-speed servo motion control system produces stunning works with precise cutting, smooth curves, and high energy strength.

9、A streamlined sheet metal body designed with dedication and ubiquitous texture, living alone in the beauty of technology.

Hot Searches