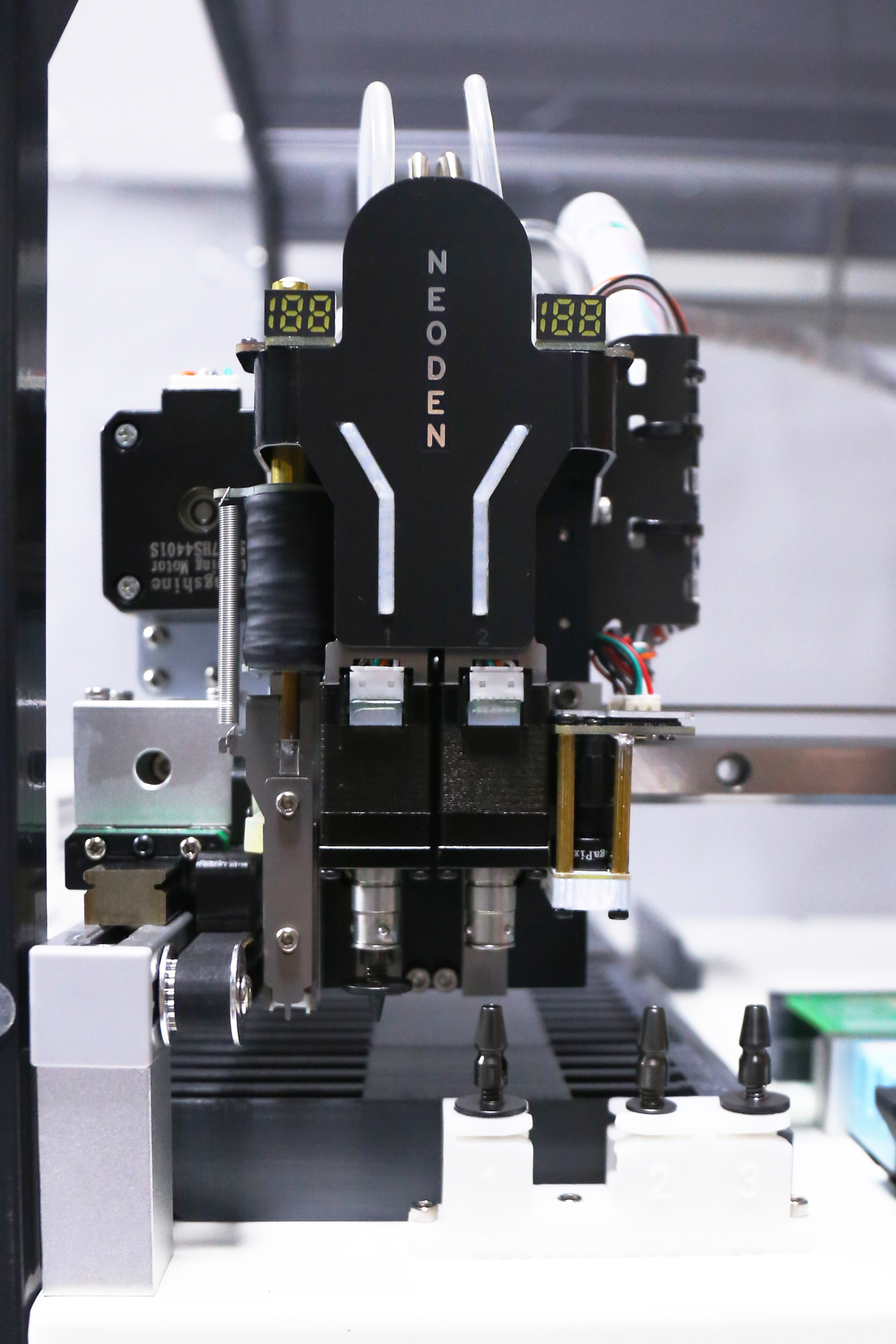

Automatic nozzle changer

help realizing nozzles changed flexibly.

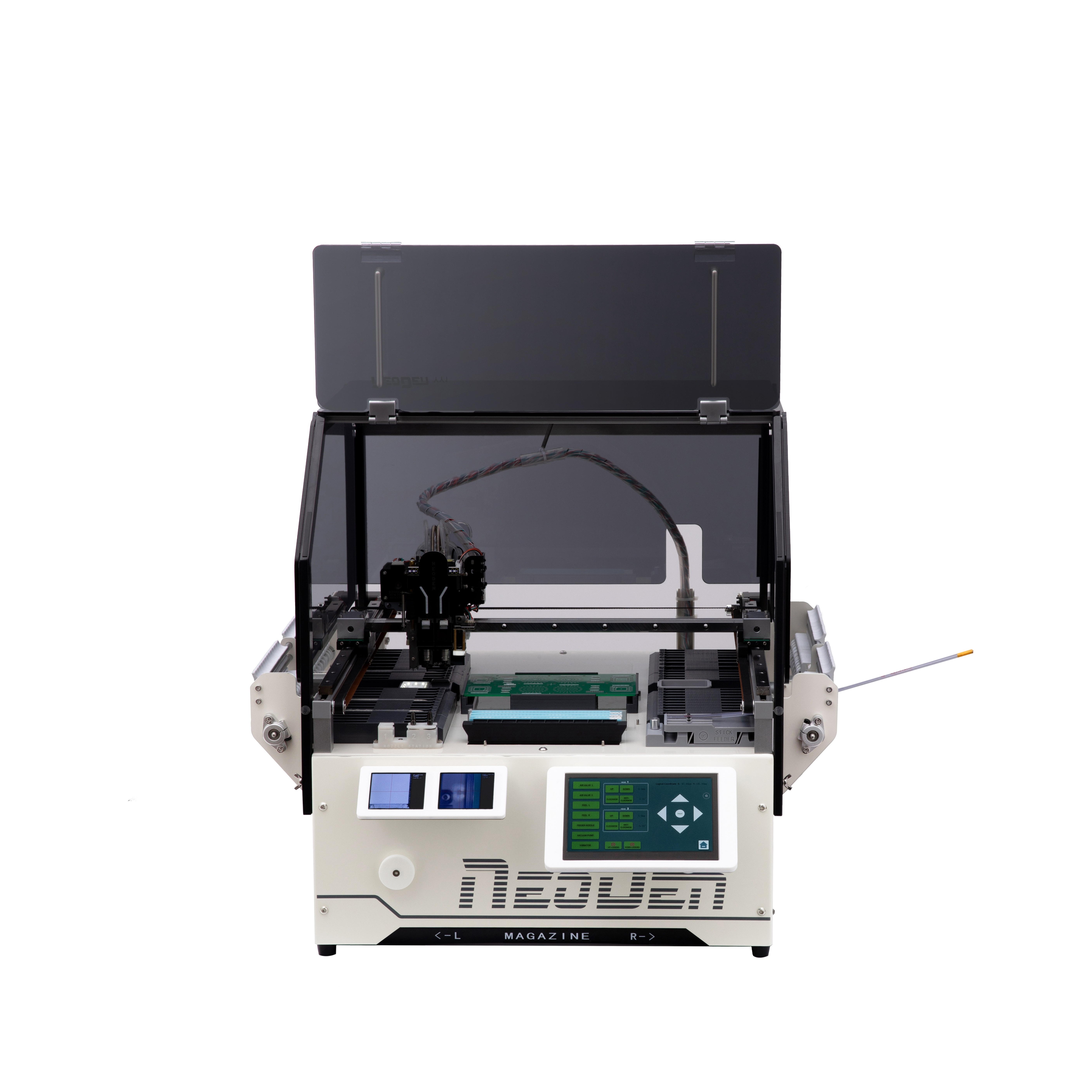

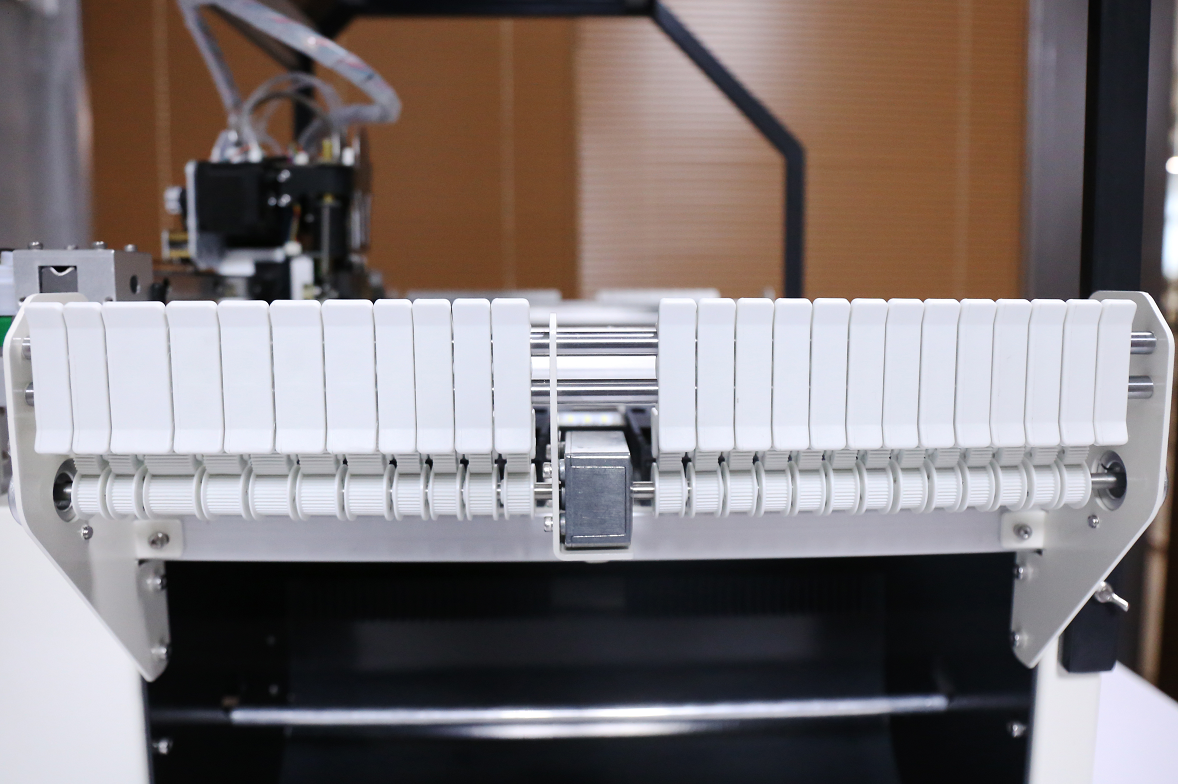

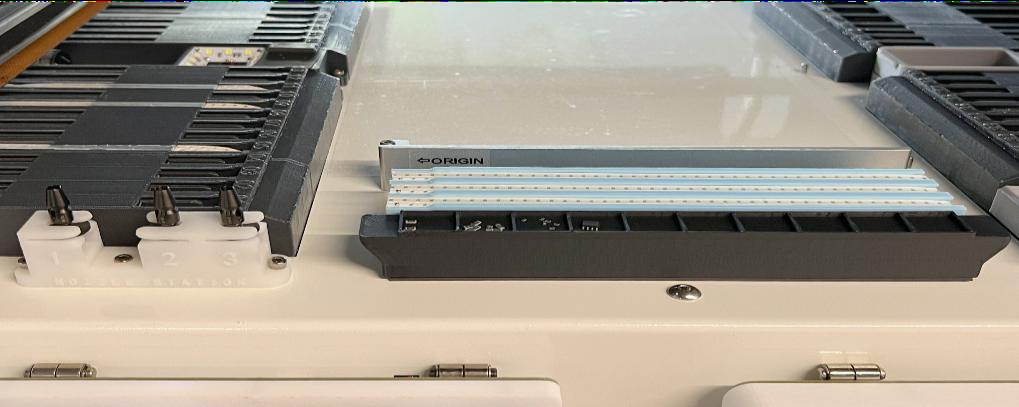

Supports bulk component feeder, strip feeder and IC tray feeder.