- Product Details

- {{item.text}}

Quick Details

-

MF:

-

[C6H7O2(OH)2CH2COONa]n

-

EINECS No.:

-

205-488-0

-

Place of Origin:

-

China

-

Type:

-

fluid loss controller and tackifier

-

Model Number:

-

drilling grade

-

Appearance:

-

white powder

-

purity:

-

55-72% or OEM

-

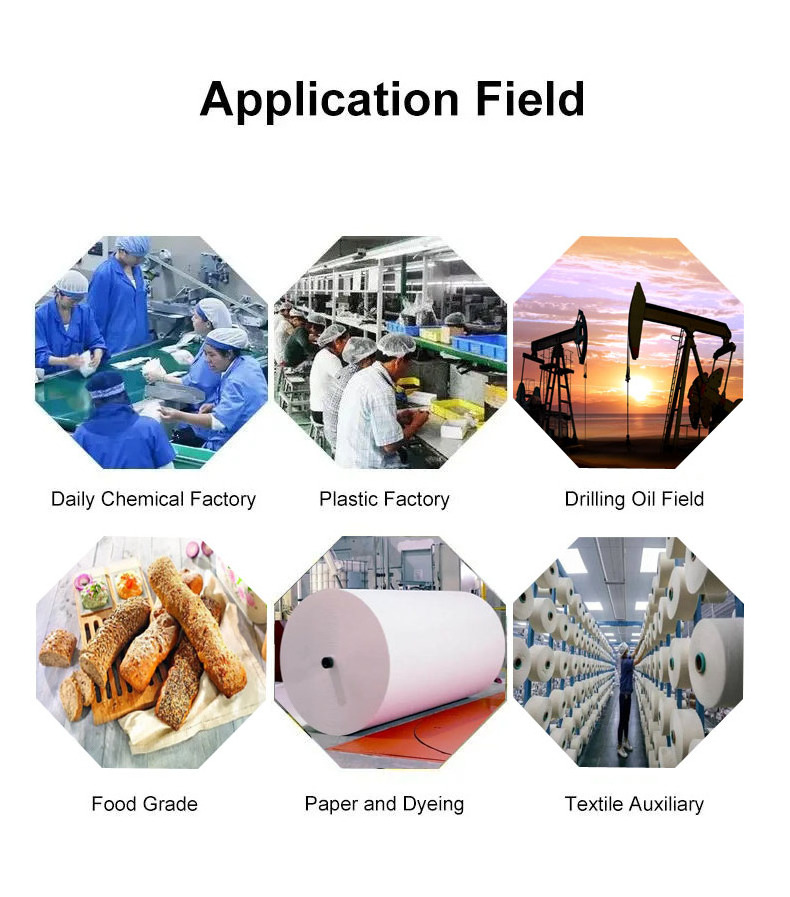

Application:

-

detergent grade

-

PH value:

-

6.0-8.5

-

degree of substitute:

-

0.65-0.80

-

Certificate:

-

ISO REACH

-

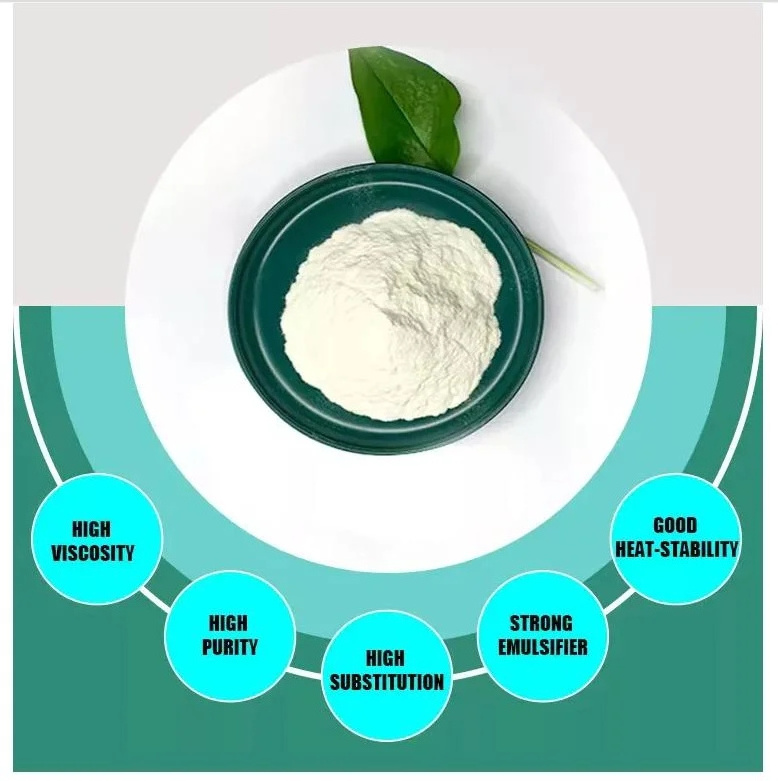

Function:

-

stabilizers and thickener

-

Material:

-

Cotton

-

Viscosity:

-

as client's requirement

-

Package:

-

25kg/bag

Quick Details

-

CAS No.:

-

9004-32-4

-

Purity:

-

≥95%

-

Other Names:

-

sodium cmc

-

MF:

-

[C6H7O2(OH)2CH2COONa]n

-

EINECS No.:

-

205-488-0

-

Place of Origin:

-

China

-

Type:

-

fluid loss controller and tackifier

-

Model Number:

-

drilling grade

-

Appearance:

-

white powder

-

purity:

-

55-72% or OEM

-

Application:

-

detergent grade

-

PH value:

-

6.0-8.5

-

degree of substitute:

-

0.65-0.80

-

Certificate:

-

ISO REACH

-

Function:

-

stabilizers and thickener

-

Material:

-

Cotton

-

Viscosity:

-

as client's requirement

-

Package:

-

25kg/bag

Product Description

Sodium Carboxymethyl Cellulose (also referred as CMC and Carboxy Methyl Cellulose) can briefly be described as an anionic

water-soluble polymer produced from naturally occurring cellulose by etherification, substituting the hydroxyl groups with

carboxymethyl groups on the cellulose chain.Being readily dissolved in hot or cold water, Sodium Carboxymethyl Cellulose CMC can

be produced in different chemical and physical properties.

water-soluble polymer produced from naturally occurring cellulose by etherification, substituting the hydroxyl groups with

carboxymethyl groups on the cellulose chain.Being readily dissolved in hot or cold water, Sodium Carboxymethyl Cellulose CMC can

be produced in different chemical and physical properties.

Specification

|

Item

|

Specification

|

|

Physical Form

|

White to off-white powder

|

|

Viscosity (1% mPa.S)

|

1500-4000

|

|

D.S

|

0.7-0.9

|

|

Purity, %

|

99.5min

|

|

pH Value 1%

|

6.5-8.5

|

|

Moisture Content, %

|

8.0max

|

|

Particle Size

|

Min.95% through 80mesh

|

|

Heavy Metals (As Pb), ppm

|

10max

|

|

Lead, ppm

|

3max

|

|

Arsenic,ppm

|

3max

|

|

Total plate count

|

500/g max

|

|

Yeast & Moulds

|

200/g max

|

|

E.Coli

|

Nil/g

|

|

Coliform bacteria

|

Nil/g

|

|

Salmonella

|

Nil/25 g

|

|

item

|

value

|

|

Classification

|

Chemical Auxiliary Agent

|

|

CAS No.

|

9004-32-4

|

|

Other Names

|

carboxyl methyl cellose

|

|

MF

|

(C6H10O6)n(C2H2O2Na)x

|

|

EINECS No.

|

265-995-8

|

|

Purity

|

99.5% min

|

|

Place of Origin

|

China

|

|

Type

|

CMC

|

|

Usage

|

Coating Auxiliary Agents, Leather Auxiliary Agents, Paper Chemicals, Petroleum Additives, Plastic Auxiliary Agents, Rubber Auxiliary Agents, Surfactants, Textile Auxiliary Agents, Water Treatment Chemicals

|

|

Model Number

|

food grade

|

|

Product name

|

CMC

|

|

HS code

|

3906901000

|

|

Appearance

|

white or milky white powder

|

|

molecular weight

|

81.39

|

|

Purity

|

99.5%

|

|

Viscosity

|

200-500mpa.s

|

|

PH value

|

6.5-8.5

|

|

Degree Of Substitute

|

0.6-0.9

|

|

Moisture

|

10% max

|

|

Application

|

food industry

|

Application

Food Grade CMC is soluble in cold water to give clear and colourless solutions with neutral flavour.

Viscosity production is the primary property of Food Grade CMC.

1) With instant products, Food Grade CMC is used to provide the required rapid build-up of viscosity, for example in powdered

beverages.

The viscosity produced by Food Grade CMC contributes to the stabilisation of frozen products such as ice cream, water ices and

ripples. Benefits include the conservation of texture and inhibition of ice crystal formation, a slow meltdown and an improved

resistance to dripping and better heat shock resistance.

2) The thickening effects of Food Grade CMC can be used in products such as salad dressings and tomato sauces. Food Grade CMC

properties that make it suitable for these applications include its rapid solubility in both hot and cold water, its good water

binding and good tolerance to low pH levels.

3) For soft drinks, Food Grade CMC provides body or mouth feel to low calorie drinks sweetened with intense sweeteners, to more

closely match the mouth feel obtained with sucrose or glucose syrup, and to inhibit 'neck ringing' by flavour oils in beverages.

4) Bakery products also benefit from incorporation of Food Grade CMC. In cake mixes and batter mixes, Food Grade CMC can improve

the volume yield as a result of its viscosity drop during baking and improve the suspension and distribution of ingredients such

as fruit. Food Grade CMC can also provide improved yields and improved moistness after storage, and be used to increase yield or

retard staling and hence prolong shelf life.

Typically the dosage level of Food Grade CMC used in food products is 0.1 - 0.3% w/w. It is normal to fix the dosage and change

the grade of CMC used to get the target viscosity required.Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle

Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Viscosity production is the primary property of Food Grade CMC.

1) With instant products, Food Grade CMC is used to provide the required rapid build-up of viscosity, for example in powdered

beverages.

The viscosity produced by Food Grade CMC contributes to the stabilisation of frozen products such as ice cream, water ices and

ripples. Benefits include the conservation of texture and inhibition of ice crystal formation, a slow meltdown and an improved

resistance to dripping and better heat shock resistance.

2) The thickening effects of Food Grade CMC can be used in products such as salad dressings and tomato sauces. Food Grade CMC

properties that make it suitable for these applications include its rapid solubility in both hot and cold water, its good water

binding and good tolerance to low pH levels.

3) For soft drinks, Food Grade CMC provides body or mouth feel to low calorie drinks sweetened with intense sweeteners, to more

closely match the mouth feel obtained with sucrose or glucose syrup, and to inhibit 'neck ringing' by flavour oils in beverages.

4) Bakery products also benefit from incorporation of Food Grade CMC. In cake mixes and batter mixes, Food Grade CMC can improve

the volume yield as a result of its viscosity drop during baking and improve the suspension and distribution of ingredients such

as fruit. Food Grade CMC can also provide improved yields and improved moistness after storage, and be used to increase yield or

retard staling and hence prolong shelf life.

Typically the dosage level of Food Grade CMC used in food products is 0.1 - 0.3% w/w. It is normal to fix the dosage and change

the grade of CMC used to get the target viscosity required.Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle

Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Packing & Delivery

25kg bag

Hot Searches