- Product Details

- {{item.text}}

Quick Details

-

Mixer capacity:

-

240T/H, 3000kg/batch

-

Electrical Design:

-

220V/380V-50Hz

-

Operation:

-

Full Auto/Manual Operation

-

Max. Capacity of Hot Aggregate Elevator:

-

Chain-bucket type elevator, 260ton/hour

-

Weighing Precision:

-

Hot aggregate ±0.3%; bitumen ±0.25%; filler:±0.3%

-

Operation Panel:

-

Computer displaying

-

Power Panel:

-

about 750KW

-

HS Code:

-

84743200

Quick Details

-

Place of Origin:

-

Henan, China

-

Product name:

-

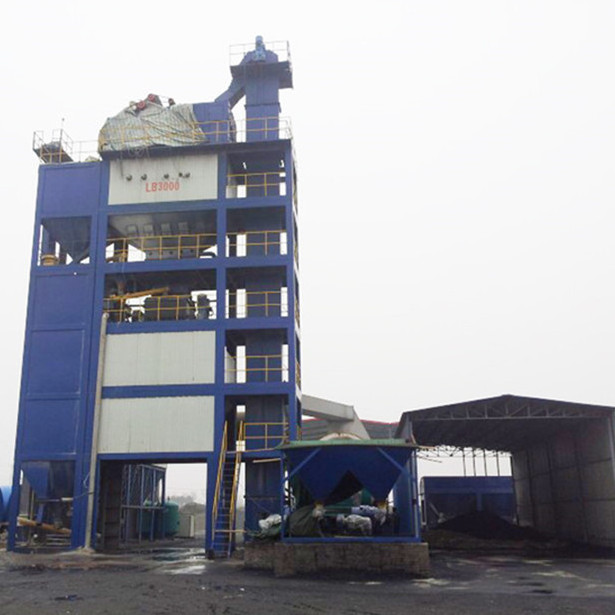

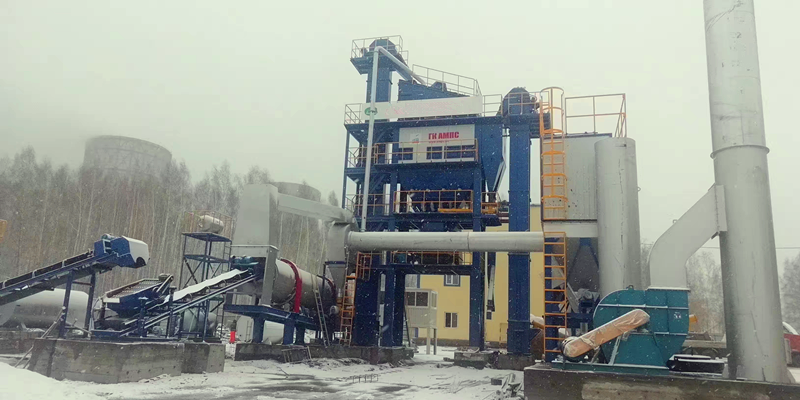

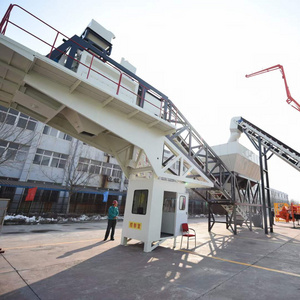

LB3000 240TPH Mobile Asphalt Batch Mixing Plant

-

Type:

-

Batch Mix / Hot Mix

-

Mixer capacity:

-

240T/H, 3000kg/batch

-

Electrical Design:

-

220V/380V-50Hz

-

Operation:

-

Full Auto/Manual Operation

-

Max. Capacity of Hot Aggregate Elevator:

-

Chain-bucket type elevator, 260ton/hour

-

Weighing Precision:

-

Hot aggregate ±0.3%; bitumen ±0.25%; filler:±0.3%

-

Operation Panel:

-

Computer displaying

-

Power Panel:

-

about 750KW

-

HS Code:

-

84743200

Product Application

LB3000 240t/h capacity of asphalt plant process types of hot mix asphalt will be the initial grade with a good cold aggregate added to the drying cylinder, after drying heating, and then heat aggregate to enhance, and then screening. Stored in a hot pot storage, and added to the mixing pan with the metered fillers and binders. Evenly mixed into asphalt mixture.

LB3000 240t/h capacity of asphalt plant process types of hot mix asphalt can fully meet high grade highway construction, municipal roads construction, airports construction and other needs , it is the ideal equipment for construction and maintenance of high-ways.

Main Features

Standard working condition mentioned contains the following factors.

A. Environmental temperature is 20 ℃ with standard atmospheric pressure; altitude ≤2000m;

B. Average moisture content of cold aggregate <5%;

C. Hot aggregate temperature <160 ℃;

D. Finished materials is medium-grained, the stone volume-weight ≥1600kg/m3;

E. Sand content <35%;

F. The ratio of aggregate shall meet the national standard. Dust content of cold aggregate ≤3%;

G. Cold aggregate should be clean enough without too much dirt or other material. Cold aggregate gradation should be continuous;

H. Cold aggregate shall not contain large amounts of oversized material, otherwise it will cause blocking, resulting in reduced ability to supply aggregate;

I. Moisture content of powder must be less than 0.5%, and there should be no lumping or arching, otherwise it will cause supplying interruption or lag, which can affect the productivity;

Pre-Sales Service

* Inquiry and consulting support.

* View our Factory.

After-Sales Service

* Training how to install and how to use the machine.

* Engineers available to service machinery overseas.

Erection/commissioning/training:

2) The seller will send 1-2 persons to guide erection in the buyer's worksite, and training operators for the buyer.

3) The buyer should afford the engineers' accommodation, local transportation fees, medical care; usually the seller will provide 15 days after service without any charge, and will ask for service cost from 16th day by USD80/day for each person, the buyer should assist the seller's to get the Visa. The seller will afford the go and return air tickets for engineers from China to the Destination country.

4) General erection time is about 25-30 working days.