- Product Details

- {{item.text}}

Quick Details

-

Power:

-

190KW, 51KW engine, water-cooled

-

Dimension(L*W*H):

-

2700*1200*2400

-

Weight:

-

4200 kg

-

Model:

-

DH0551

-

Tank Size:

-

Liquid capacity: 5000L (1320Gallon)

-

Tank Size-2:

-

Working capacity: 3830L (1010Gallon)

-

Agitation:

-

mechanical agitator with helical paddle

-

Rotating speed of mixer shaft:

-

0-110rpm

-

horizontal conveying distance:

-

60 meter

-

Spraying guns type:

-

fixed standing gun and pipe gun

-

Height of fence:

-

1100 mm

-

Options:

-

Stainless steel material

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DH machinery

-

Power:

-

190KW, 51KW engine, water-cooled

-

Dimension(L*W*H):

-

2700*1200*2400

-

Weight:

-

4200 kg

-

Model:

-

DH0551

-

Tank Size:

-

Liquid capacity: 5000L (1320Gallon)

-

Tank Size-2:

-

Working capacity: 3830L (1010Gallon)

-

Agitation:

-

mechanical agitator with helical paddle

-

Rotating speed of mixer shaft:

-

0-110rpm

-

horizontal conveying distance:

-

60 meter

-

Spraying guns type:

-

fixed standing gun and pipe gun

-

Height of fence:

-

1100 mm

-

Options:

-

Stainless steel material

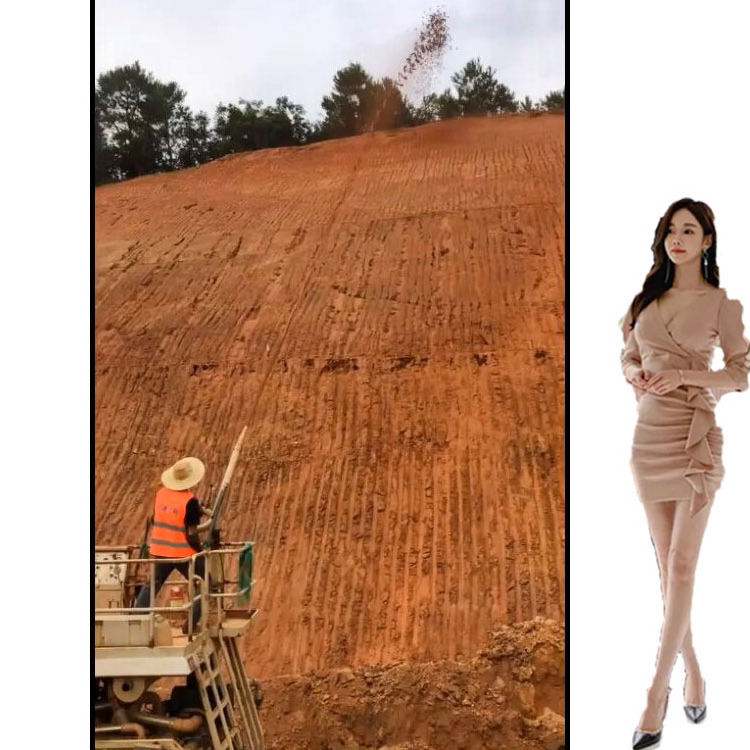

Spray seeding is more and more applied in road greening. The application of seeding spraying technology in vegetation restoration and slope protection project.

The soil spraying seeder involves in planting permanent vegetation, spraying slurry, slope protection, grassing and erosion prevention.

Soil spraying seeder driven by single diesel, electronic control, easy operation, especially suitable for outdoor conditions, applicable to all kinds of rock slope, hard soil, poor soil, acidic soil, arid zones, clay soil and coastal dam.etc

Product Description

1.The material of the main structure is made of high quality structural steel. No matter how worse the conditions are, it ensure seeder sturdy and solid. And it has reasonable, generous appearance. Painted with imported painting to guarantee of three-year no fading

.2. Advanced technology, it even works for mud materials which have poor mobility, no blocking, and no stopping, well

adaptation of various materials, big output pressure.

3. Two mixing models, blades mixing and circular spray, are powerful enough to ensure the spraying mixture in the planting process is in fully suspended and fully mixed stated, evenly emitting the mixture of raw materials at one time.

4.It has strong power, the maximum head can be above 60m, and be equipped with many types of spraying

guns, which extend the maximum operation scope from 200m to 300m; fan-shaped spray nozzle or mist spraying is more suitable for close-distance planting to meet various requirements.

5.This machine has wide usage, not only can be applied in spraying planting for rice, grass, tress, flowers, seeds, and other

crops, but also in irrigation, fertilize, pesticide spraying and other daily care, soil improvement work.

6.Our machine is a soil spraying seeder, but it can also use as a hydroseeder.

Specification

|

Model

|

DH5000

|

DH3000

|

DH2000

|

DH1200

|

|||

|

Power

|

51KW, engine, water-cooled

|

53KW, China diesel engine, water-cooled

|

17kw gasoline engine, air cooled

|

|

|||

|

Tank Size

|

Liquid capacity: 5000L (1320Gallon)

|

Liquid capacity: 3000L (800Gallon)

|

Liquid capacity: 2000L (530Gallon)

|

Liquid capacity: 1200L (317Gallon)

|

|||

|

|

|

|

|

|

|||

|

|

Working capacity: 3830L (1010Gallon)

|

Working capacity: 2550L (670Gallon)

|

Working capacity: 1700L(450Gallon)

|

Working capacity: 1000L (264Gallon)

|

|||

|

Pump

|

Centrifugal pump: 4’’x2’’ (10.2X5cm), 73m³/h@7bar, 25mm solid clearance

|

Centrifugal pump:4’’x2’’ (10X5cm), 70m³/h@7bar, 10mm solid clearance

|

Centrifugal pump: 3’’x1.5’’ (7.5X3.75cm), 15m³/h@5bar, 19mm solid clearance

|

|

|||

|

|

|

|

|

|

|||

|

Agitation

|

mechanical agitator with helical paddle orientation and liquid recirculation

|

|

|

|

|||

|

Rotating speed of mixer shaft

|

0-110rpm

|

|

|

|

|||

|

Maximum horizontal conveying distance

|

60m

|

|

35m

|

26m

|

|||

|

|

|

|

|

|

|||

|

Spraying guns type

|

fixed standing gun and pipe gun

|

|

|

Hose gun

|

|||

|

Height of fence

|

1100mm

|

|

——

|

——

|

|||

|

Options

|

Stainless steel material for whole unit, Hose Reel with hose, Remote control unit, Trailer

|

|

|

|

|||

|

Model

|

DH10000

|

DH8000-100

|

DH8000-103

|

DH8000-83

|

|||

|

Power

|

120KW, engine, water-cooled

|

100KW, engine, water-cooled

|

103KW @ 220rpm engine, water-cooled

|

83KW, China diesel engine, water-cooled

|

|||

|

Tank Size

|

Liquid capacity: 10000L (2640Gallon)

|

Liquid capacity: 8000L (2100Gallon)

|

|

|

|||

|

|

Working capacity: 8950L (2360Gallon)

|

Working capacity: 7300L (1930Gallon)

|

|

|

|||

|

Pump

|

Centrifugal pump: 5’’x2.5’’ (12.7X6.4cm), 90m³/h@11bar, 25mm solid clearance

|

Centrifugal pump:5’’x2.5’’ (12.6X7.6cm), 100m³/h@11bar, 20mm solid clearance

|

Centrifugal pump:5’’x2.5’’ (12.7X6.4cm), 100m³/h (440gpm) @ 11bar, 1’’(2.5cm) solid clearance

|

Centrifugal pump:5’’x2.5’’ (12.6X6.3cm), 90m³/h@10bar, 20mm solid clearance

|

|||

|

Agitation

|

Twin mechanical agitators with helical paddle orientation and liquid recirculation

|

mechanical agitator with helical paddle orientation and liquid recirculation

|

|

|

|||

|

Rotating speed of mixer shaft

|

0-110rpm

|

|

0-130rpm

|

0-110rpm

|

|||

|

Maximum horizontal conveying distance

|

70m

|

|

|

65m

|

|||

|

Spraying guns type

|

fixed standing gun and pipe gun

|

|

|

|

|||

|

Height of fence

|

1100mm

|

|

|

|

|||

|

Options

|

Stainless steel material for whole unit, Hose Reel with hose, Remote control unit, Trailer

|

|

|

|

|||

Equipment spraying workflow

1. Spraying operations:

After the preparation work is complete, normal spraying operations can begin. Here's how to do it:

(1) Press the horn on the operating platform to remind people around you to start working and pay attention to safety.

(2) Start the diesel engine, step on the mixing clutch pedal, and move the gear handle to the "reverse" position to ensure that when the centrifugal pump is working, the material moves toward the front of the box.

(3) After the materials are mixed evenly and ready for spraying, lift the lift valve. Appropriately adjust the spray angle of the nozzle head according to the conditions of the construction site and select the appropriate nozzle caliber. Check whether the return pipe valve is closed before spraying. Open the injection valve, and then slowly release the clutch lever of the pump. According to the distance of injection, appropriately "increase" or "decrease" the diesel engine throttle to control the lift of the material and achieve the desired effect (if spraying below When the pressure is lower, the return valve can be opened according to the situation to reduce the pressure).

2. Emergency treatment

If the spray gun head suddenly fails to discharge material during construction, quickly move the clutch lever of the centrifugal pump to the "off" state.

(1) Check whether the nozzle is blocked. After removing the nozzle and taking out the foreign matter, turn the centrifugal pump back on to continue the spraying operation;

(2) Check whether the pump port is blocked. Remove the telescopic tube from the pump feed pipe and clean the material in the pipe.

(3) Due to the poor fluidity of the material, during normal spraying operations, the material lift suddenly appears to be small and accompanied by strong noise. This situation is normal. At this time, the pump's clutch lever should be moved to the "off" state immediately, wait for about 15 seconds, then move the clutch lever to the "on" state, and start normal spraying operations.

(4) When long-distance operations are required, rubber pipes should be connected for spray sowing.

3. The tank should be cleaned after the spraying operation is completed

. How to clean the tank: add clean water to the tank, open the return valve, let the pump work, flush the tank and pipes, and then spray out to clean the machine; then stop the throttle control switch and stirring speed control switch in reset location to facilitate next operation.

Auxiliary materials added to the spray seeder:

1. It is recommended that customers add ‘slope greening adhesive’.

Function: It increases the cohesion between materials during mixing, has a certain thickening effect on the mixed soil, reduces the addition of soil, and makes spraying smoother. The spraying construction on the slope has certain functions of resisting rain erosion, protecting the slope, and strengthening the adhesion with the slope. However, do not add too much, otherwise it will cause soil compaction. It is recommended to add about 1-6 pounds per jar depending on soil conditions.

2. Greening water-retaining agent (select according to the weather, maintenance conditions, and soil quality)

3. Nutrient soil (select peat soil and peat soil as appropriate)

4. Rice husks, sawdust, grass fiber, broken rice straw (within 2-3 cm in length), peanut shells, etc. can be added if the geology and soil for spraying are good. If the soil quality is poor and the sand content is high, rice husks can be added. Adding shells and sawdust has good adsorption properties. If the slope is slightly steep, it is recommended to add grass fiber and break up the straw.

5. Organic fertilizers

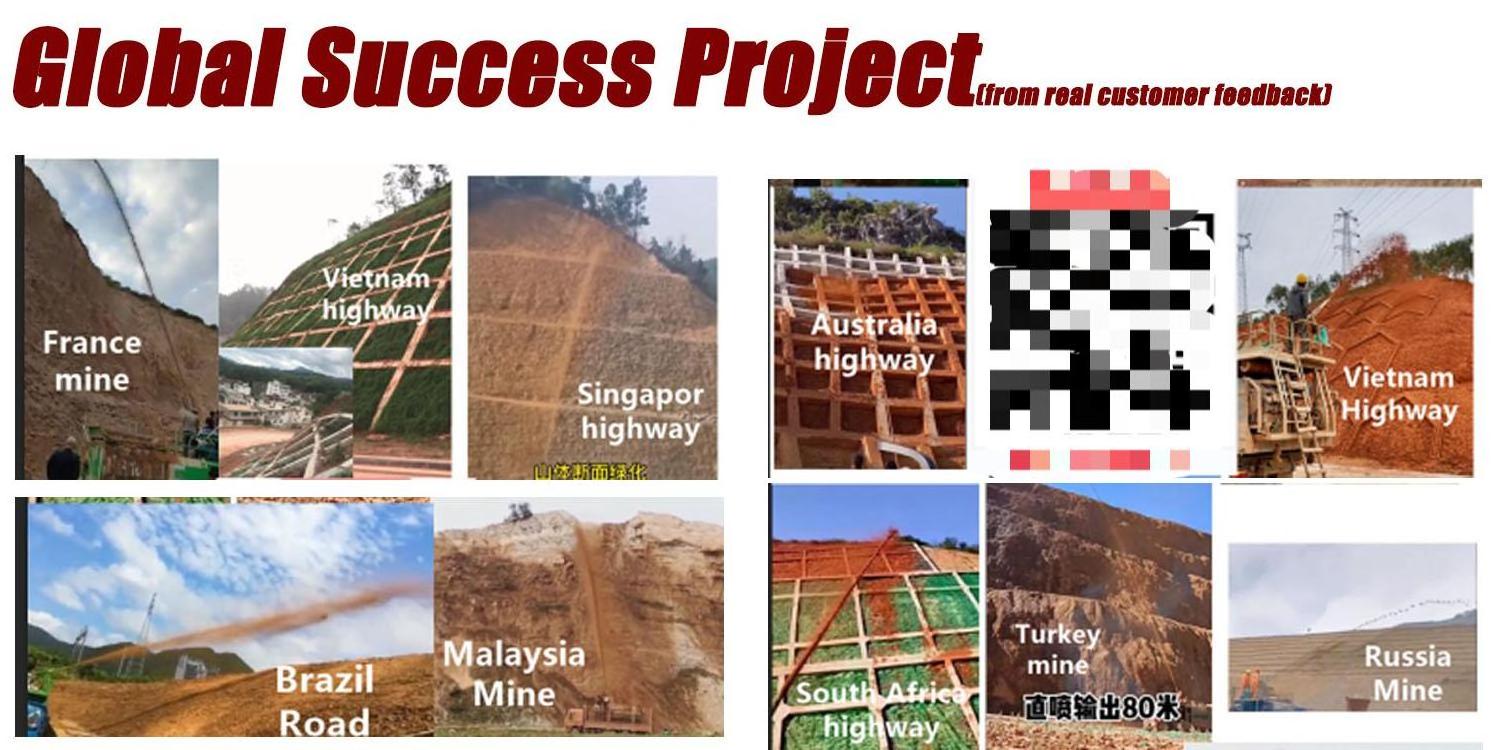

Our Services for you ❤

1.Whole process guidance With more than 15 years of service experience, we will spare no effort to provide support in selecting equipment, customizing production lines, improving supply chain, and post-optimization etc.

2.Provide a full set of construction method and equipment training Provide design and construction solutions in terms of cost budget / progress improvement / quality control / safety management.

3.After-sales service system Fully track the service system, focus on customer needs, first-class speed, skills, attitude, and provide support for customer

4.Support customization Relying on our powerful flexible production line, we can give you the right to fully choose the mold,drive method, accessories upgrade, shell material, appearance color and Logo etc.

5.Extensive spare parts service The spare parts warehouse of more than 50,000 square meters can meet the timely replacement and supplement of any wearing parts.

6.Support sea, land and air transportation We can ship products to every corner of the world. If you need, we also support a series of tedious tasks such as customs clearance and tail end delivery.

Hot Searches