- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

1800

-

Dimension(L*W*H):

-

7240*4700*5100

-

Weight (T):

-

18.5 T

-

Range of Spindle Speed(r.p.m):

-

1 - 6000 r.p.m

-

Spindle Motor Power(kW):

-

15-18.5

-

Max. Table Load(kg):

-

5000 kg

-

Feed Speed(mm/min):

-

1 - 10000 mm/min

-

Rapid Feed Speed(m/min):

-

15/15/12

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

weisite

-

Voltage:

-

220v/110v/380v

-

Marketing Type:

-

New Product 2024

-

Product name:

-

3-axis Vertical Cnc Machining Center

-

Keywords:

-

Vmc Machine Center

-

CNC or Not:

-

CNC Systemn

-

CNC Controller:

-

FANUC 0i Mate MD (Others Optional)

-

Machine Type:

-

DMTG Vertical Machining Center

-

Spindle speed:

-

8000/12000rpm

-

Spindle:

-

Taiwan 8000rpm Spindle

-

Precision:

-

0.005/300 Mm

-

Usage:

-

Machining Process

-

Motor:

-

Japan YASKAWA Servo Motor

Quick Details

-

Table Size (mm):

-

2500*1600

-

Number of Axes:

-

3, 4, 5

-

Table Travel (X) (mm):

-

2500

-

Table Travel (Y) (mm):

-

1800

-

Dimension(L*W*H):

-

7240*4700*5100

-

Weight (T):

-

18.5 T

-

Range of Spindle Speed(r.p.m):

-

1 - 6000 r.p.m

-

Spindle Motor Power(kW):

-

15-18.5

-

Max. Table Load(kg):

-

5000 kg

-

Feed Speed(mm/min):

-

1 - 10000 mm/min

-

Rapid Feed Speed(m/min):

-

15/15/12

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

weisite

-

Voltage:

-

220v/110v/380v

-

Marketing Type:

-

New Product 2024

-

Product name:

-

3-axis Vertical Cnc Machining Center

-

Keywords:

-

Vmc Machine Center

-

CNC or Not:

-

CNC Systemn

-

CNC Controller:

-

FANUC 0i Mate MD (Others Optional)

-

Machine Type:

-

DMTG Vertical Machining Center

-

Spindle speed:

-

8000/12000rpm

-

Spindle:

-

Taiwan 8000rpm Spindle

-

Precision:

-

0.005/300 Mm

-

Usage:

-

Machining Process

-

Motor:

-

Japan YASKAWA Servo Motor

Product descriptions from the supplier

Product description

|

specifications

|

unit

|

GMC2518

|

|

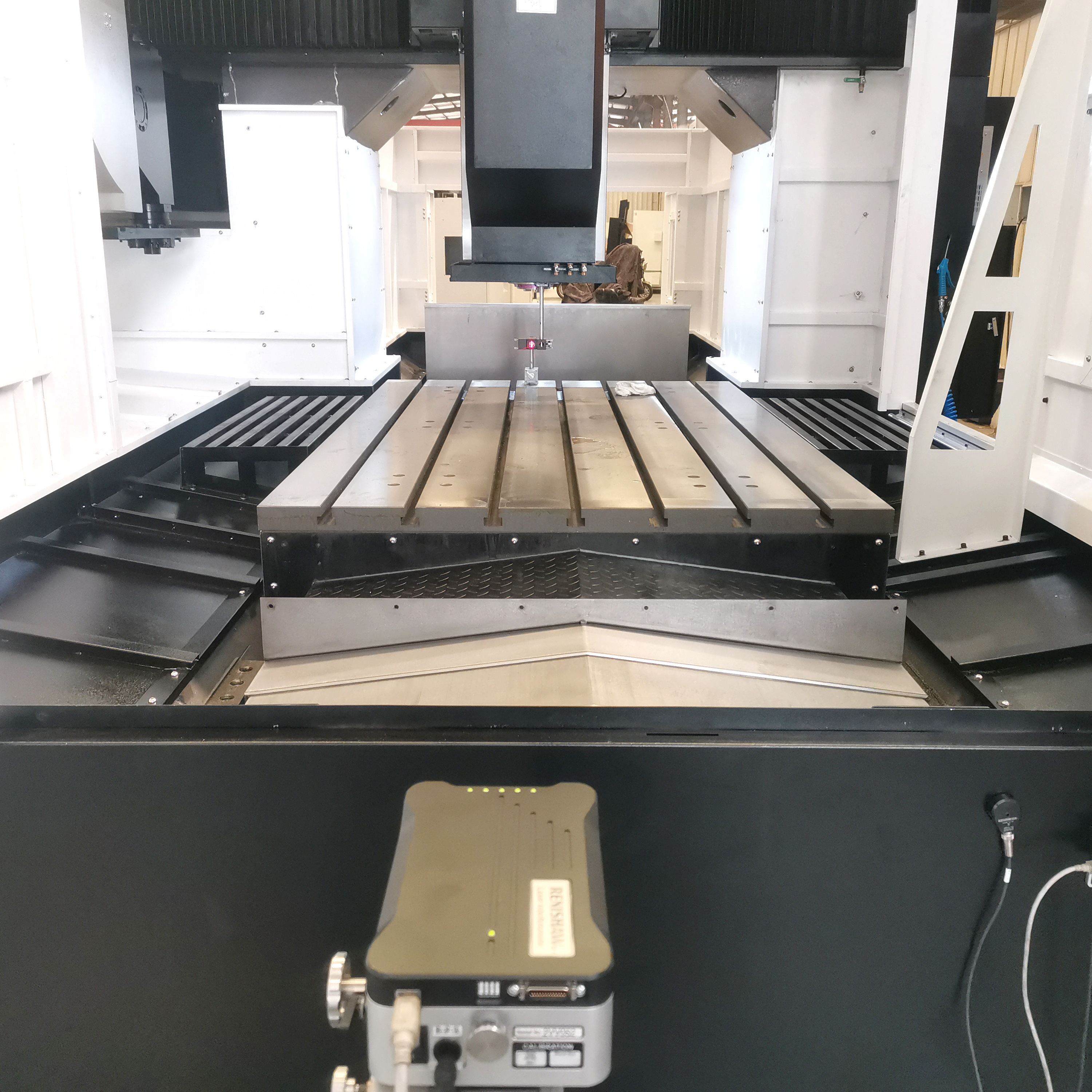

Table size

|

mm

|

2500*1600

|

|

Max.table load

|

kg

|

7000

|

|

X axis travel

|

mm

|

2500

|

|

Y axis travel

|

mm

|

1800

|

|

Z axis travel

|

mm

|

1000

|

|

Distance between spindle nose and table surface

|

mm

|

150-1150

|

|

T slot

|

mm

|

9-22-180

|

|

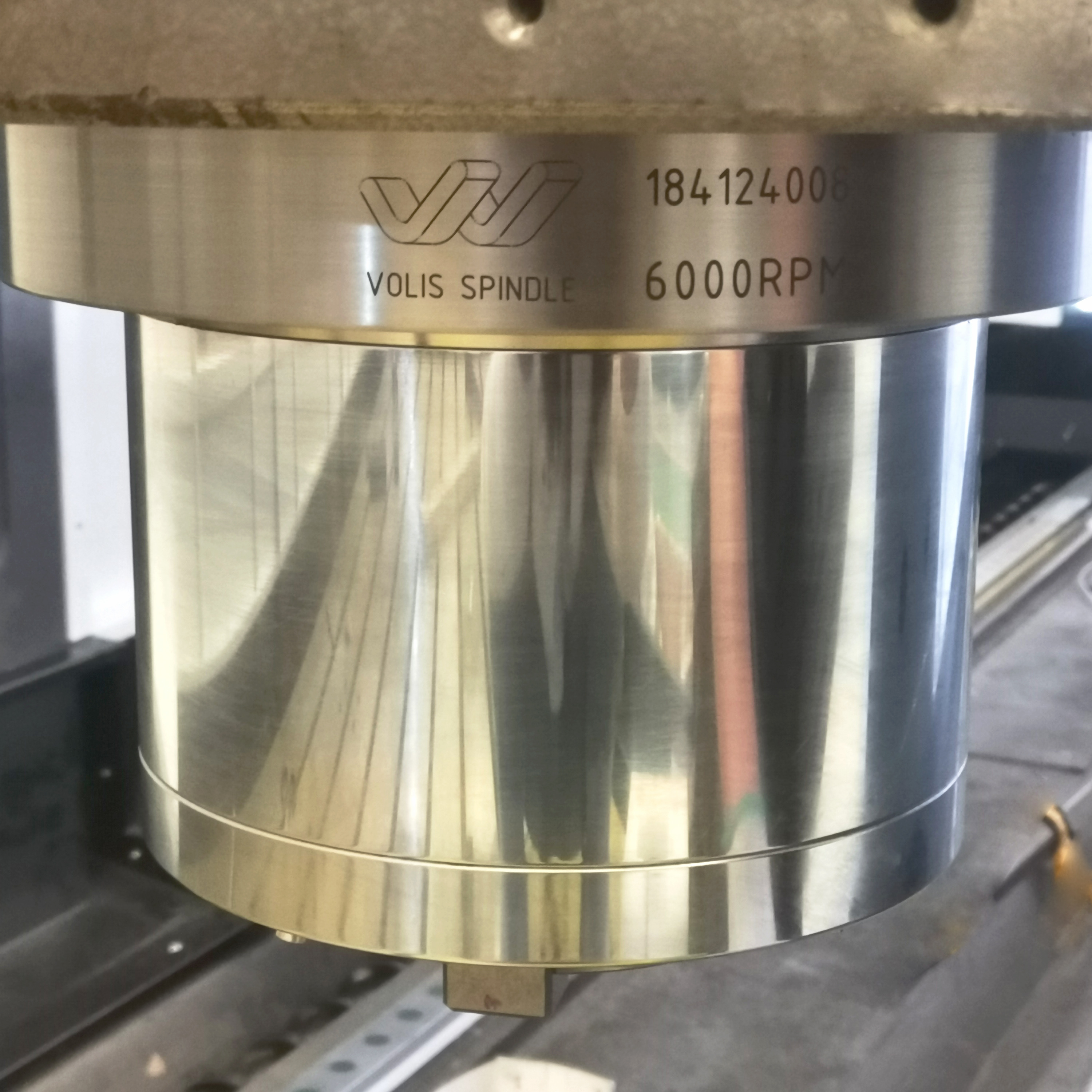

Spindle taper

|

|

BT50

|

|

Max. spindle speed

|

rpm

|

1-6000

|

|

Main motor power

|

kw

|

15-18.5

|

|

X/Y/Z axis servo motor torque

|

N.M

|

22/22/22

|

|

X/Y/Z motor connection

|

|

direct

|

|

X/Y/Z guide rail form

|

|

3 axis linear guide rail

|

|

Automatic tools changer

|

|

24 arm type

|

|

X/Y/Z axis rapid traverse

|

M/min

|

15/15/12

|

|

Cutting feed speed

|

M/min

|

1-10000

|

|

Position accuracy

|

mm

|

0.005

|

|

Repeat positioning accuracy

|

mm

|

0.003

|

|

Machine dimension

|

mm

|

7240*4700*5100

|

|

Machine weight

|

T

|

20

|

Peculiarity:

1. Automatic broach, pneumatic punching mechanism

2.

Automatic centralized forced oil lubrication of lead screw and guide rail

3.

High-pressure water cooling

4.

Fully protected sheet metal shield

5.

Air cooling

6. Mobile hand pulse generator

Products Description

overview

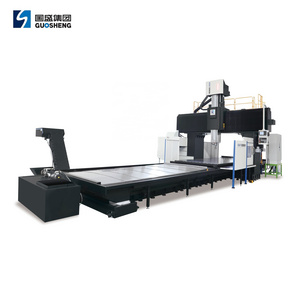

The feed axis of the machining center is controlled by X, Y and Z coordinates, the main axis is driven by servo motor power,andthe tool store capacity is 24 disc tool stores. Can achieve a variety of disc, plate, shell, CAM, mold and other complexparts once clamping, complete drilling, milling, boring, expanding, reaming, tapping and other process processing, suitablefor the production of many varieties, small and medium-sized batch products, the processingcomplex, high-precision partscan show its advantages.

Taiwan tool magazine

1.Standard Taiwan robotic arm 24/32 disc type tool magazine

2.Tool changing speed 2-3 seconds

3.Brand:OKADA

Taiwan high precision spindle unit

1.The spindle taper is BT40/BT50

2.The spindle speed is 8000rpm/10,000rpm./12000rpm, etc

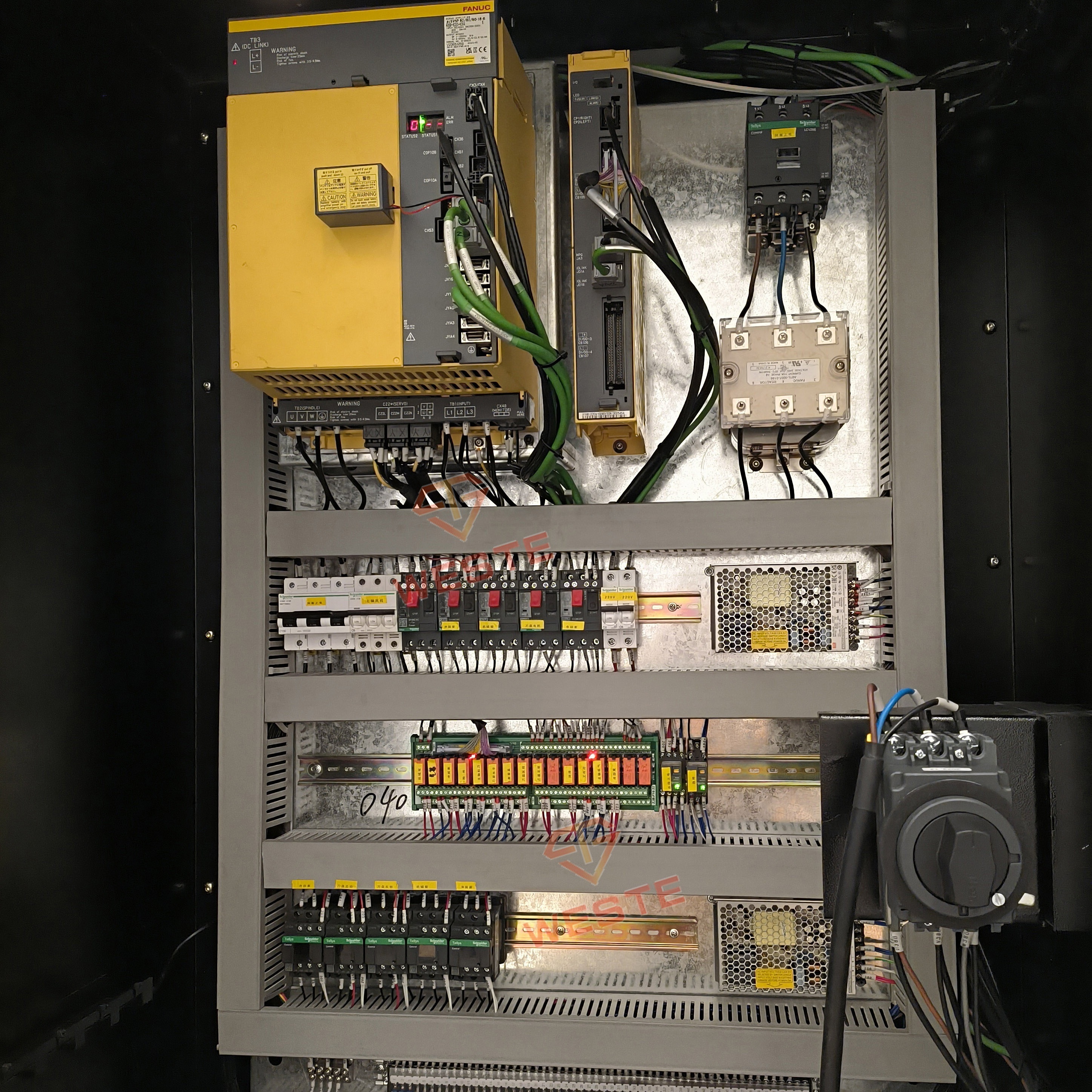

Standard configuration industrial electrical cabinet air conditioning

Cooling the electric box better

Schneider electrical components

1.Standard complete set of Schneider electrical components

2.Standard quick plug

Volumetric centralized thin oil lubricating system

Working principle: The internal piston is distributed by means of conveying pressure push (BFD type), and the lubricating oil which has been quantified in the displacement distributor is forcibly transported to each lubrication point.

Taiwan gold MINDMAN pneumatic components

1.This product uses polytetrafluoroethylene, polyurethane, nitrile rubber seals, durable.

2.Brand:Taiwan gold MINDMAN

Processed product case

Company profile

Shandong West CNC Machine Tool Co., Ltd. is a CNC machine tool manufacturing company that integrates design, manufacturing, sales, and service, covering an area of more than 5000 square meters. The company has been developing for five years, and its main products include vertical machining centers, horizontal machining centers, gantry machining centers, five axis machining centers, CNC inclined bed lathes, CNC milling machines, ordinary milling machines, drilling machine series, and other CNC equipment.

After more than ten years of development, the company has a stable supply chain to provide guarantees for the supply of raw materials. The precise quality inspection equipment and modern management mode have laid a solid foundation for producing high-quality products. All factory equipment will go through strict quality control processes such as quality inspection, copying, and re inspection, ensuring that each equipment is of high quality. At the same time, each machine tool has complete quality control records, a comprehensive after-sales service system, and experienced engineers to ensure fast after-sales service.

The company has a group of experienced mechanical engineering designers and skilled assembly technicians, adhering to the principles of technological innovation, management innovation, and talent innovation to provide customers with excellent quality services. We warmly welcome domestic and foreign friends to discuss business, enhance understanding, and work together to create brilliance!

Certificate display

Exhibitions and customer visits

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe

Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight .

5: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

Hot Searches