- Product Details

- {{item.text}}

Quick Details

-

H Content (%):

-

N/A

-

Ash Content (%):

-

N/A

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Juli Tech

-

Model Number:

-

Juli Color Connector

-

Dimensions:

-

Custom size

-

Working Temperature:

-

-50 'c to 150 'c

-

Volatile:

-

N/A

-

Material:

-

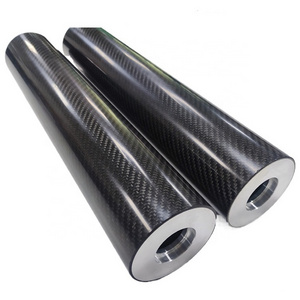

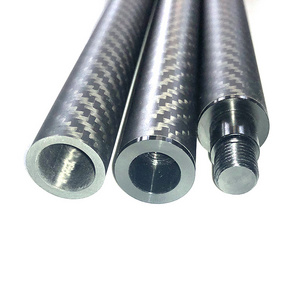

100% Carbon Fiber

-

Surface:

-

3k Twill/plain Glossy/matte

-

Technology:

-

Roll-wrapped

-

Certification:

-

ISO9001

-

Tensile Strength:

-

3.6-3.8Gpa

-

HS CODE:

-

3916909000

-

Length:

-

Customized Length

-

Size:

-

Customized Size

-

Usage:

-

Sport

-

Raw material:

-

T1000 Carbon fiber

Quick Details

-

C Content (%):

-

100%

-

S Content (%):

-

N/M

-

N Content (%):

-

N/A

-

H Content (%):

-

N/A

-

Ash Content (%):

-

N/A

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Juli Tech

-

Model Number:

-

Juli Color Connector

-

Dimensions:

-

Custom size

-

Working Temperature:

-

-50 'c to 150 'c

-

Volatile:

-

N/A

-

Material:

-

100% Carbon Fiber

-

Surface:

-

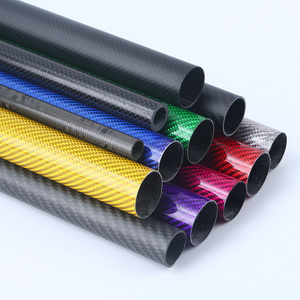

3k Twill/plain Glossy/matte

-

Technology:

-

Roll-wrapped

-

Certification:

-

ISO9001

-

Tensile Strength:

-

3.6-3.8Gpa

-

HS CODE:

-

3916909000

-

Length:

-

Customized Length

-

Size:

-

Customized Size

-

Usage:

-

Sport

-

Raw material:

-

T1000 Carbon fiber

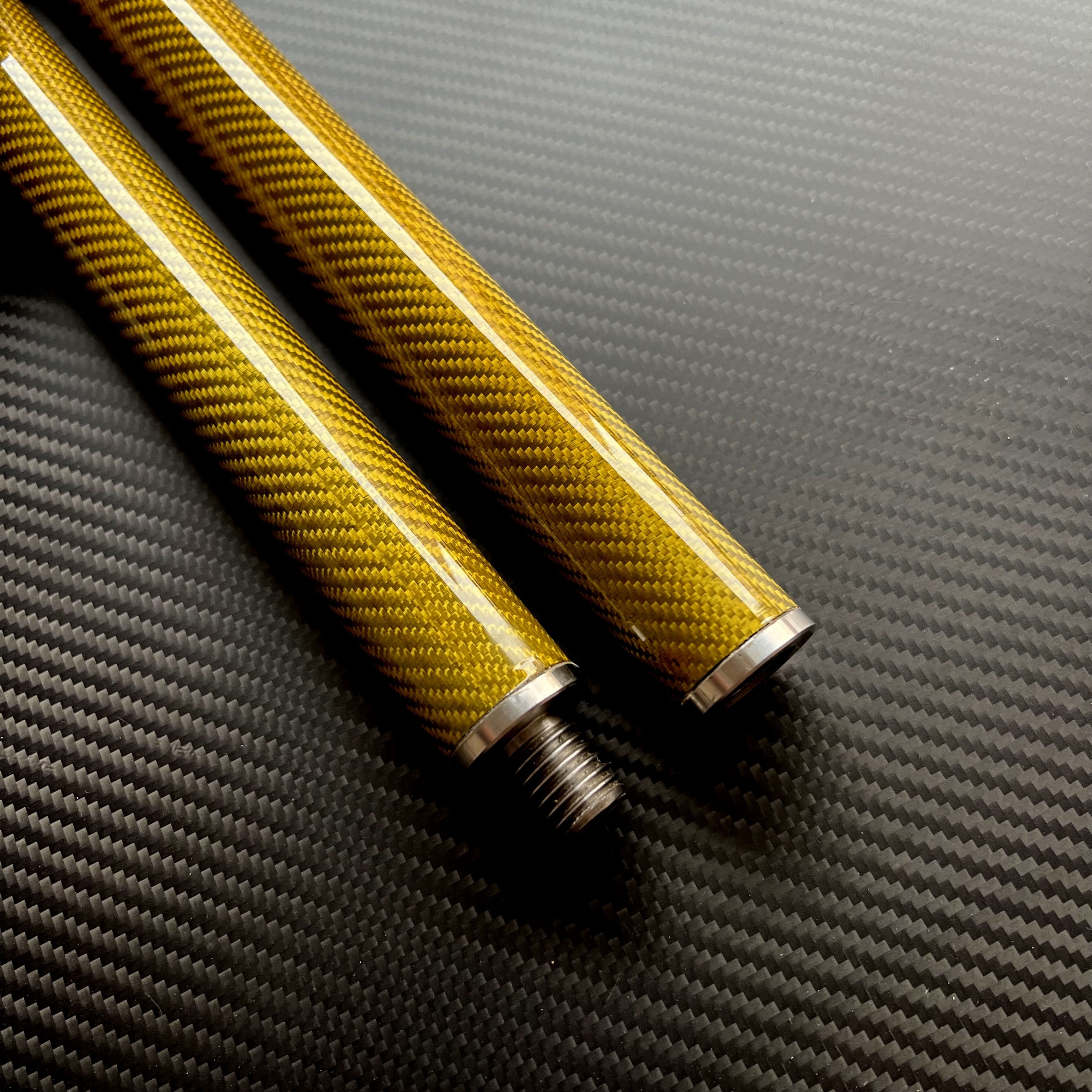

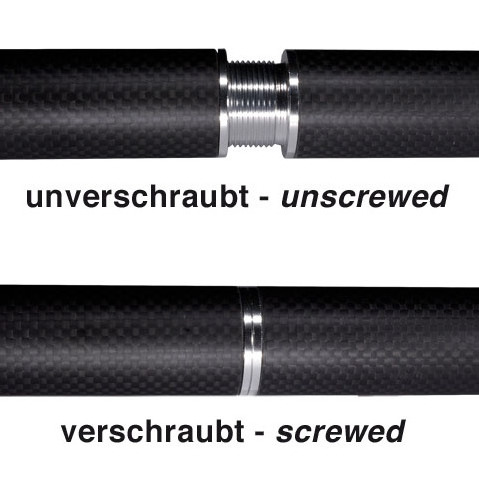

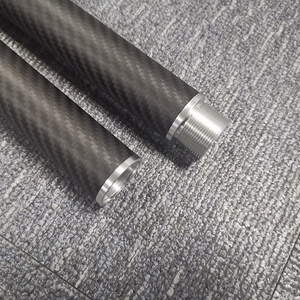

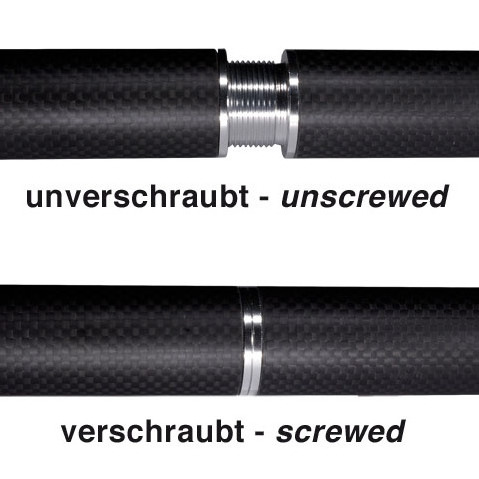

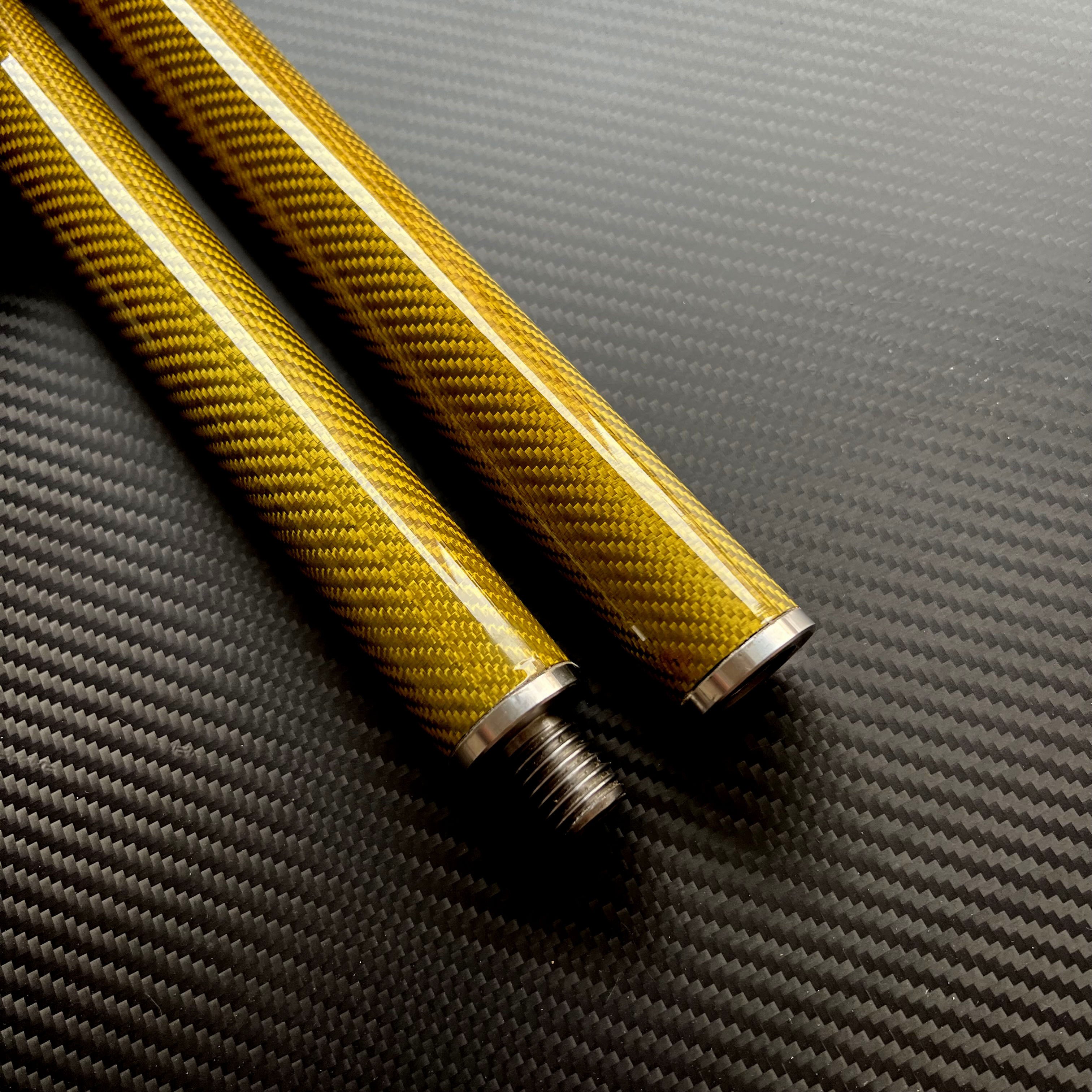

Gold colorful carbon fiber tube connector 3k twill carbon fiber tubing aluminum threaded connectors

Product Description

|

TECHNICAL DATA SHEET

|

|

|

|

|

||||

|

Manufacturing Method :

|

Carbon fiber Compression Moulding Process

|

|

|

|

||||

|

Structure

|

UW

|

U = Unidirectional Prepreg

|

W= Woven Prepreg

|

|

||||

|

Raw Materials :

|

Carbon fiber , Epoxy

|

|

|

|

||||

|

Diameter Range O.D.

|

make to order

|

|

|

|

||||

|

Wall Thickness

|

0.5 to 10mm

|

|

|

|

||||

|

Length :

|

3.5 Meters Maximum

|

|

|

|

||||

|

Colors :

|

RAL Code Or Black

|

|

|

|

||||

|

Water Absorption

|

< 1,5w- %

|

|

|

|

||||

|

Denisty

|

1.5g/cm3

|

|

|

|

||||

|

FIBER TYPE

|

HS Carbon

|

HM Carbon

|

HM Carbon

|

|

||||

|

Stiffness

|

90 - 100 Gpa

|

|

120- 180 Gpa

|

|

||||

|

Bending Strength

|

>600 Mpa

|

|

>500 Mpa

|

|

||||

|

Tensile Strength

|

>650 Mpa

|

|

>550 Mpa

|

|

||||

|

Denisity

|

>1.5g/cm3

|

|

>1.5g/cm3

|

|

||||

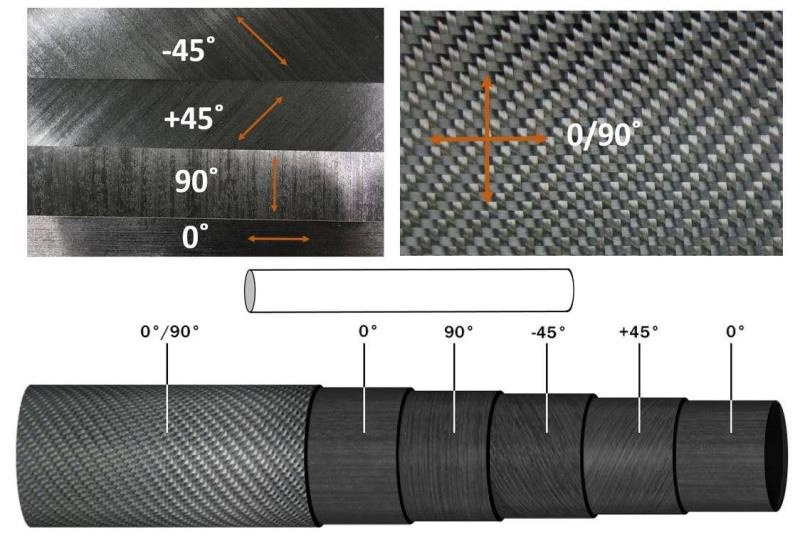

Structure of our Carbon Fiber Tube

TOP THREE FIBER ORIENTATIONS

0 ° ORIENTATION

If a part will only be loaded in one direction it’s ideal to have all the fibers oriented in that direction. Pultruded rod and tubing are examples of a part that contains only 0° fibers

90° ORIENTATION

As previously mentioned, 90° layers are often added to tubes to make them more resistant to buckling and crushing. High concentrations of 90° or “hoop” layers can also be found in pressure vessels.

+/- 45 ° ORIENTATION

45° layers serve different purposes depending on the application. You’ll almost always see a +45° paired adjacent to a -45° layer. This is to keep the laminate “balanced” and from forcefully twisting when loaded.

The Manufacturing Process

Product Application

CLEANDING POLE

CAMERA SLIDER

BOAT PUSH POLE

Case Show

Our service

* We are an Make to order factory ,We do not have them on stock , but , we accept make small samples for you

* when you need design a pole , you only need tell us the dimension of carbon fiber tubes ,we will design it for you

* Make Samples takes 5 to 7 days , For formal Order 100 pcs ,Within 14 to 18 days

CONTACT US

Contact Person : Curtis Wu

Whatsapp : + 86 13652464970 Skype : China.frp2 Wechat : ag13652464970

Hot Searches