- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5

-

Driven Type:

-

Electirc & Pneumatic

-

Voltage:

-

100-240V customized

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Atpack

-

Dimension(L*W*H):

-

1200*500*950mm

-

Weight:

-

90 KG

-

Processing Types:

-

piston filling

-

Machine Structure Material:

-

SUS304

-

Material Contact Part Material:

-

SUS 316L

-

Function:

-

filling

-

Capacity:

-

5-38BPM

-

Marketing Type:

-

New Product 2023

Quick Details

-

Machinery Capacity:

-

400BPH, 500BPH, 1000BPH

-

Packaging Material:

-

Glass, Metal, Paper, Plastic, Wood, Other

-

Filling Material:

-

Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±0.5

-

Driven Type:

-

Electirc & Pneumatic

-

Voltage:

-

100-240V customized

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Atpack

-

Dimension(L*W*H):

-

1200*500*950mm

-

Weight:

-

90 KG

-

Processing Types:

-

piston filling

-

Machine Structure Material:

-

SUS304

-

Material Contact Part Material:

-

SUS 316L

-

Function:

-

filling

-

Capacity:

-

5-38BPM

-

Marketing Type:

-

New Product 2023

Product Application

Volumetric fillers measure and dispense free flowing products - such as thin and/or moderately dense liquids - onto a container. Each machine is equipped with one or more volumetric pistons. Each fill/release cycle consists of an intake stroke, where the product is withdrawn from the container or hopper and taken into the product cylinder. The down stroke commences as soon as the product cylinder has reached its predetermined fill level. The piston pushes the product out of the cylinder and into the container.

The amount of product to dispense is set by a simple adjustment of the length of the piston stroke (the distance covered by the piston). The adjustment is performed by turning an small adjusting wheel located at table-top level. If the stroke is reduced the volume of dispensed product decreases. On the other hand, lengthening the piston stroke will result more product being dispensed. Once the set, the piston filler will dispense accurately and repeatedly. Two repeated cycles can be performed to fill volumes that are higher than the cylinder capacity.

Our Volumetric Piston Fillers are used by industries in the Food & Beverage, Cosmetics, Personal Care, Agricultural, Animal Care, Pharmaceutical, and Chemical fields.

|

Mode

|

Filling Range

|

Filling Accuracy

|

Capacity

(Automatic)

|

Capacity

(Manual)

|

|

VCF-1

|

0.1~1ml

|

±0.5%

|

60~90

|

30~50

|

|

VCF-5

|

0.5~5ml

|

±0.5%

|

55~85

|

25~45

|

|

VCF-10

|

1~10ml

|

±0.5%

|

50~80

|

25~45

|

|

VCF-20

|

2~20ml

|

±0.5%

|

45~70

|

23~43

|

|

VCF-50

|

5~50ml

|

±0.5%

|

40~60

|

20~38

|

|

VCF-100

|

10~100ml

|

±0.5%

|

35~55

|

20~38

|

|

VCF-250

|

25~250ml

|

±0.5%

|

20~40

|

18~30

|

|

VCF-500

|

50~500ml

|

±0.5%

|

15~30

|

15~22

|

|

VCF-1000

|

100~1000ml

|

±0.5%

|

10~22

|

10~18

|

|

VCF-1500

|

100~1500ml

|

±0.5%

|

8~18

|

8~15

|

|

VCF-2000

|

200~2000ml

|

±0.5%

|

7~16

|

7~13

|

|

VCF-3000

|

300~3000ml

|

±0.5%

|

6~13

|

6~10

|

|

VCF-5000

|

500~5000ml

|

±0.5%

|

5~10

|

5~8

|

Main Features

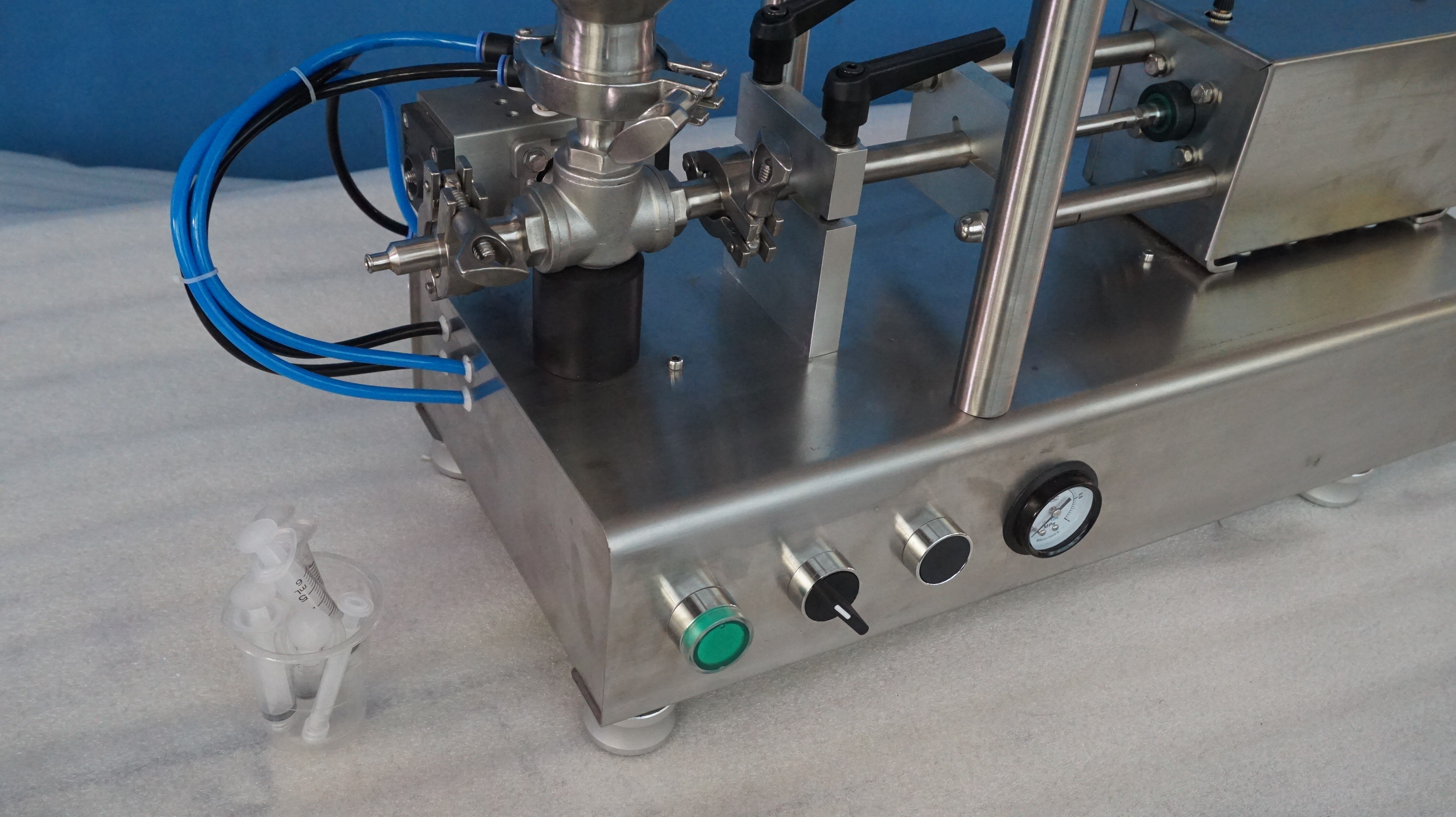

· Approximate Speed: 5 - 38 pcs/min(depending on filling volume, operator speed, product density, draw length, a fill speed, among others)

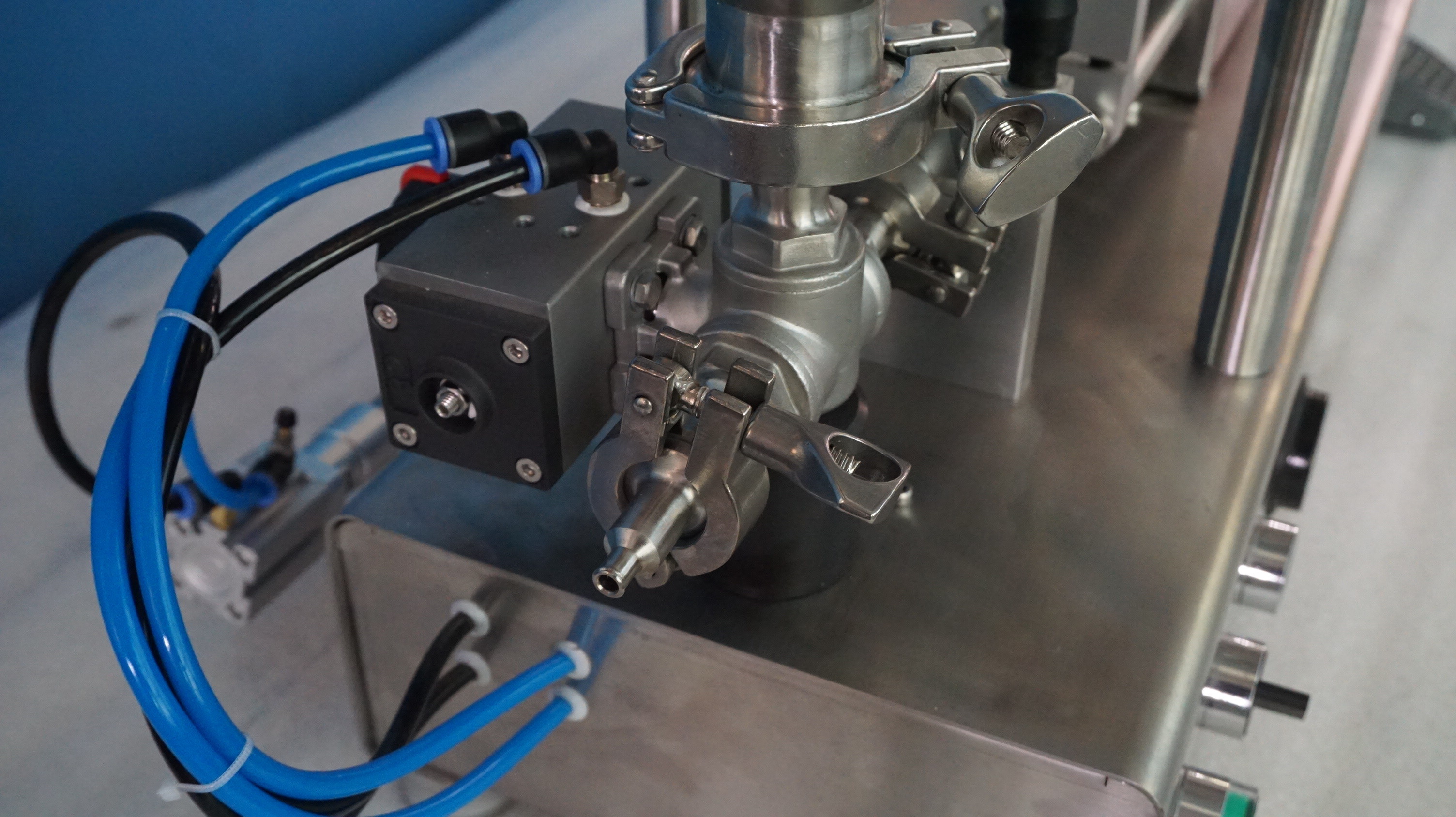

· All Parts in Contact with Product are Food Grade(SUS316/SUS316L)

· Stainless Steel Construction(SS 304, 1.5mm thickness)

· Electrical-pneumatic Operation

· Fluoropolymer elastomer O-ring System

· Adjustable Volumetric Piston System with Numeric Reference Display

· Piston Feed Speed Adjustment

· No-drip Option Included and Installed

· Extremely Accurate(±0.5%)

·

Extremely Easy to Clean and Maintain

· Sanitary Stainless Steel Quick Disconnect Fittings

· Extremely Easy to Operate

· Quick Connect/Disconnect Pneumatic Fittings.

Semi-automatic and automatic mode

Adopting advanced pneumatic parts (Germany FESTO or Taiwan AIRTAC)

Cylinder made up of 316L stainless steel and polyethylene with Teflon,it accord with cGMP standard.

Optional manual control heating and mixing function

The whole vavle is made of SUS316.

We can customize e asy-clean vavle,this type vavle is easier to disassemble and clean than the standard vavle.The parts are corrosion-resistant.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* 24 hours Hotline: 86-13917505479 (English speaking engineer)

|

Packaging

|

|

|

|

Size

|

120(L) * 50 (W) * 95 (D)

|

|

|

Weight

|

100KG

|

|

|

Packaging Details

|

The package adopts outside package (standard export wooden case) and inner package (stretch film), it is suitable for long distance transport, damp proofing, rust prevention, and shockproof etc, and also suitable for sea, land transport and entirety lifting.

|

|