- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AOMAG

-

Model Number:

-

AOMAG0077

-

MOQ:

-

100 Pcs

-

Founded:

-

1996

-

Certification:

-

ISO9001:2008, ISO/TS16949:2009 and RoHS

-

Magnetization direction:

-

Customized , Axially, Diametrically

-

Supply Ability:

-

20000000 Piece/Pieces per Month

-

Port:

-

Fuzhou/Ningbo/Shanghai

Quick Details

-

Tolerance:

-

±0.05mm

-

Grade:

-

Sintered NdFeB

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

AOMAG

-

Model Number:

-

AOMAG0077

-

MOQ:

-

100 Pcs

-

Founded:

-

1996

-

Certification:

-

ISO9001:2008, ISO/TS16949:2009 and RoHS

-

Magnetization direction:

-

Customized , Axially, Diametrically

-

Supply Ability:

-

20000000 Piece/Pieces per Month

-

Port:

-

Fuzhou/Ningbo/Shanghai

Products Description

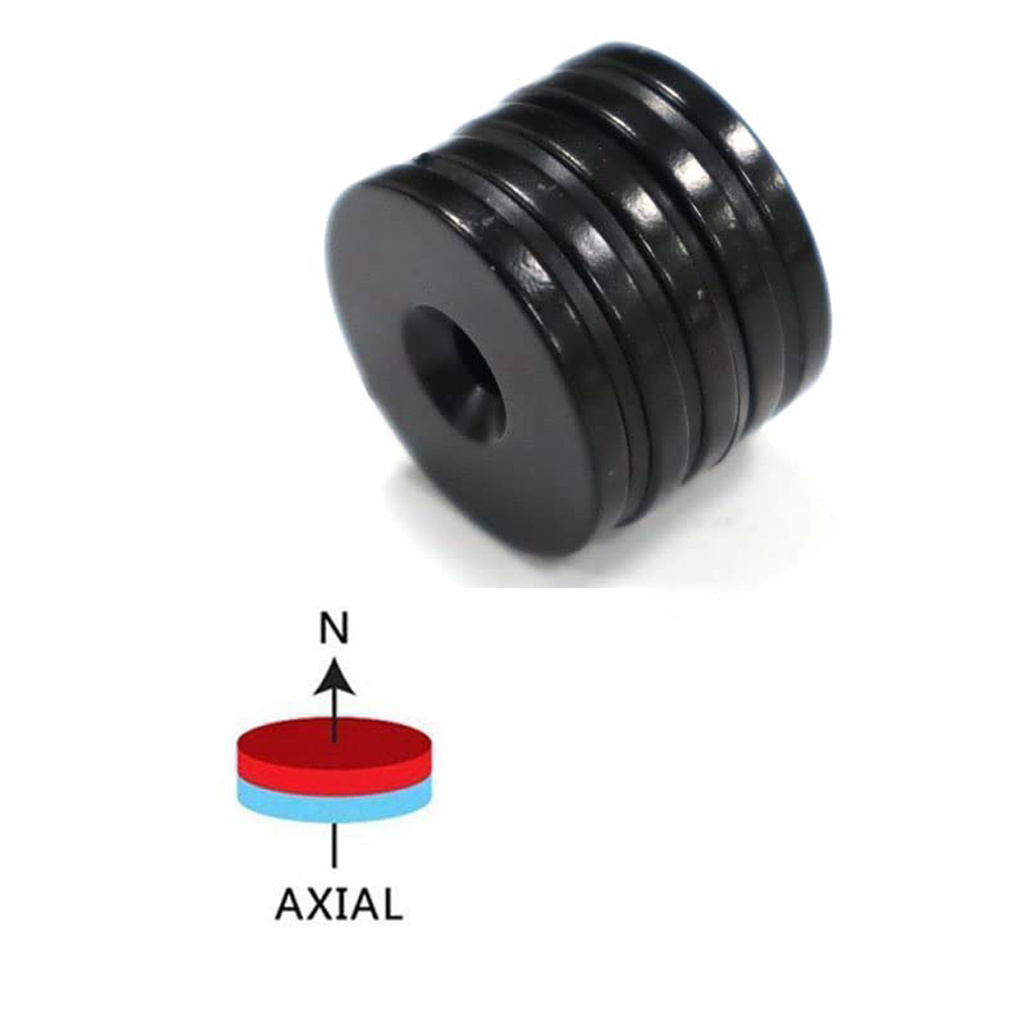

Black Epoxy Coated Neodymium Disc Countersunk Hole Magnets

Neodymium Countersunk Magnets ,also called Counterbored Magnets are a unique type of neodymium disc/block magnet with a countersunk hole to fit a screw perfectly. Magnets with countersunk mounting holes allow them to be screwed into place with the screw head flush, making them ideal for any DIY task. Common uses for these magnets include DIY, Cabinet making, retail units and shelving units.All our neodymium countersunk magnets are available with a countersink on the north face of the magnet or on the south face.

Application

Servo motor,Brushless motor, Linear Motor, Automotive Motor, HEV& EV motor, Robot Driving Motor, Inverter Compressor Motor , Rail

Transit Traction Motor, Consumer Electronics, Wind turbine, Energy-saving Elevator, Loudspeaker, Magnetic switch, VCM, MRI,

Magnetic separator, sensor etc.

Transit Traction Motor, Consumer Electronics, Wind turbine, Energy-saving Elevator, Loudspeaker, Magnetic switch, VCM, MRI,

Magnetic separator, sensor etc.

Magnetized direction

Thickness Magnetized, but Axially, Diametrical, Multipoles and Radial magnetization are also available, Customized magnetization

is welcome.

is welcome.

N35 N38 N40 N42 N45 Permanent Magnets Hole Round Magnets Neodymium Round Magnets With Countersunk Hole Coated with Black Epoxy

Specification

|

Products

|

black round magnets with holes

|

|

Brand

|

AOMAG

|

|

Place of Origin

|

China

|

|

Founded

|

1996

|

|

Business Type

|

Manufacturer

(Any shape and size of Neodymium can be customized)

|

|

Size

|

Customized according to customer requirements

|

|

Delivery Time

|

15-30 days

|

|

Shape

|

Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes and more.

Customized shapes for Rare Earth Magnets are available.

|

|

Tolerance

|

±0.05mm

|

|

Grade

|

N33-N52, N35M-N50M, N35H-N52H, N35SH-N52SH, N35UH-N45UH, N35EH-N42EH

|

|

Coating

|

Ni-Cu-Ni, Nickel, Zn, Gold, Silver, Copper, Epoxy, Chemical, PTFE, Parylene, Everlube, Passivation and more.

|

|

Processing Service

|

Bending, Welding, Decoiling, Cutting, Punching, Moulding

|

Customized Service

We Accept Customized Services:

1) Shape and Dimension Requirements

2) Material and Coating Requirements

3)Requirements for Magnetization Direction

4) Magnet Grade Requirements

5) Surface treatment requirements (plating requirements)

High Quality NdFeB Magnets:

NdFeB of Various Sizes,Shape and Coating can be customized with favorable price and high quality. Magnet grades can be customized from N32 to N52.Please contact us.

Common Coating

Plating /Coatings :

Neodymium magnets are a composition of mostly Neodymium, Iron and Boron. If left exposed to the elements, the iron in the magnet will rust. To protect the magnet from corrosion and to strengthen the brittle magnet material, it is usually preferable for the magnet to be coated. There are a variety of options for coatings, but nickel is the most common and usually preferred. Some other options for coating are zinc, tin, copper, epoxy, silver and gold.

Magnet Grades:

Magnetizing Direction

The magnetizing direction have Axial Magnetizing,Radial Magnetizing,muti-pole magnetizing.

Special direction of magnetization can be customized as required.

Common direction of magnetization showed in picture bellow:

1> Disc, cylinder and Ring shape magnet can be magnetized Axially or Diametrically.

2> Rectangle shape magnets can be magnetized through Thickness, Length or Width.

3> Arc shape magnets can be magnetized Diametrically, through Width or Thickness.

Hot Searches