- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Numerical control system, rectangular linear guide rail, ball screw, reducer

-

warranty period:

-

1 year

-

color:

-

According to user requirements

-

processing method:

-

Continuous scanning, simultaneous, segmented

-

Processing (quenching) workpiece range:

-

maxlength :800mm,Diameter :≤50mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shining

-

Weight (KG):

-

5000

-

Core Components:

-

Numerical control system, rectangular linear guide rail, ball screw, reducer

-

warranty period:

-

1 year

-

color:

-

According to user requirements

-

processing method:

-

Continuous scanning, simultaneous, segmented

-

Processing (quenching) workpiece range:

-

maxlength :800mm,Diameter :≤50mm

Its characteristic:

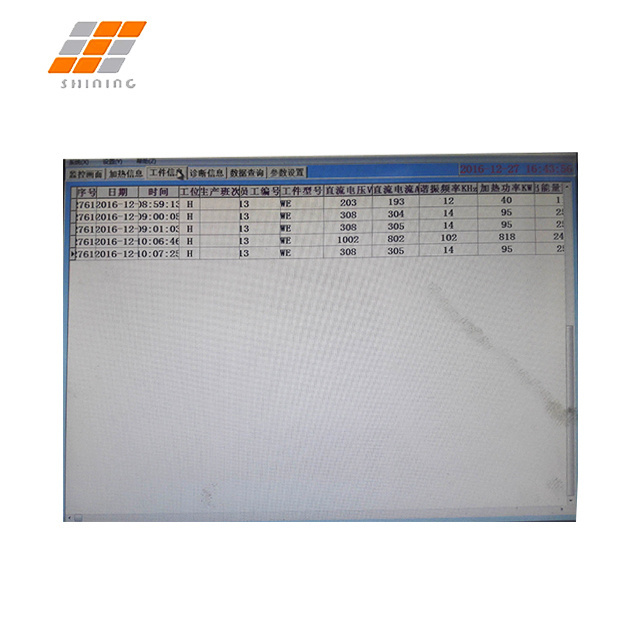

Shining Induction standard configuration: Total quality control function, Remote diagnosis function Optional configuration .

Function selection:

1. Control system;

2. Automation realization: Built-in truss robot or Joint universal robot;

3.Quenching machine structure form: Single work station, double work station, rotary disk type, (continuous or step) linear;

4.Tempering forms: Direct docking induction tempering, automatic docking with the net back to the furnace;

5.feeding and unloading form: Automatically interconnect with the upper end device or configure an automatic feeding tray. Automatically interconnect with the lower device or configure an automatic unloading tray.

|

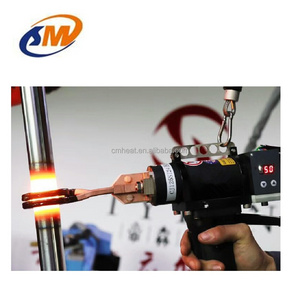

application

|

All shaft and disk parts

|

|

Processing (quenching) temperature range

|

Meet technical requirements

|

|

processing method

|

Continuous scanning, simultaneous, segmented

|

|

type of cooling

|

Spray liquid

|

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness for various types of induction heating machines.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 60 to 90 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing, assembly,

testing and packaging

Q: What can you do if the machine broken?

A: We will give you some spare parts free of charge during the one-year shelf life of the machine.For the customers who have bought the machine, if there is any problem with the machine, take a photo or record a video to us. We will guide the customers to perform the repair.If it still cannot solve the problem, we can send our engineers to your factory.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the induction heating line, we will welcome a lot of cooperation.

A: We are factory with professional production team and service consciousness for various types of induction heating machines.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 60 to 90 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing, assembly,

testing and packaging

Q: What can you do if the machine broken?

A: We will give you some spare parts free of charge during the one-year shelf life of the machine.For the customers who have bought the machine, if there is any problem with the machine, take a photo or record a video to us. We will guide the customers to perform the repair.If it still cannot solve the problem, we can send our engineers to your factory.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the induction heating line, we will welcome a lot of cooperation.

Hot Searches