- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Villa

-

Design Style:

-

Modern

-

Place of Origin:

-

Beijing, China

-

Model Number:

-

H-300

-

Raw Material:

-

Natural wood

-

Average length:

-

300 microns

-

Bulk density:

-

110-160 g/L

-

Average thickness:

-

40 microns

-

Combustion residue (850℃4h):

-

≤10%

-

Whiteness:

-

65% absolute value at 461nm

-

PH:

-

neutral

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

NONE, Others

-

Application:

-

Villa

-

Design Style:

-

Modern

-

Place of Origin:

-

Beijing, China

-

Model Number:

-

H-300

-

Raw Material:

-

Natural wood

-

Average length:

-

300 microns

-

Bulk density:

-

110-160 g/L

-

Average thickness:

-

40 microns

-

Combustion residue (850℃4h):

-

≤10%

-

Whiteness:

-

65% absolute value at 461nm

-

PH:

-

neutral

|

1

|

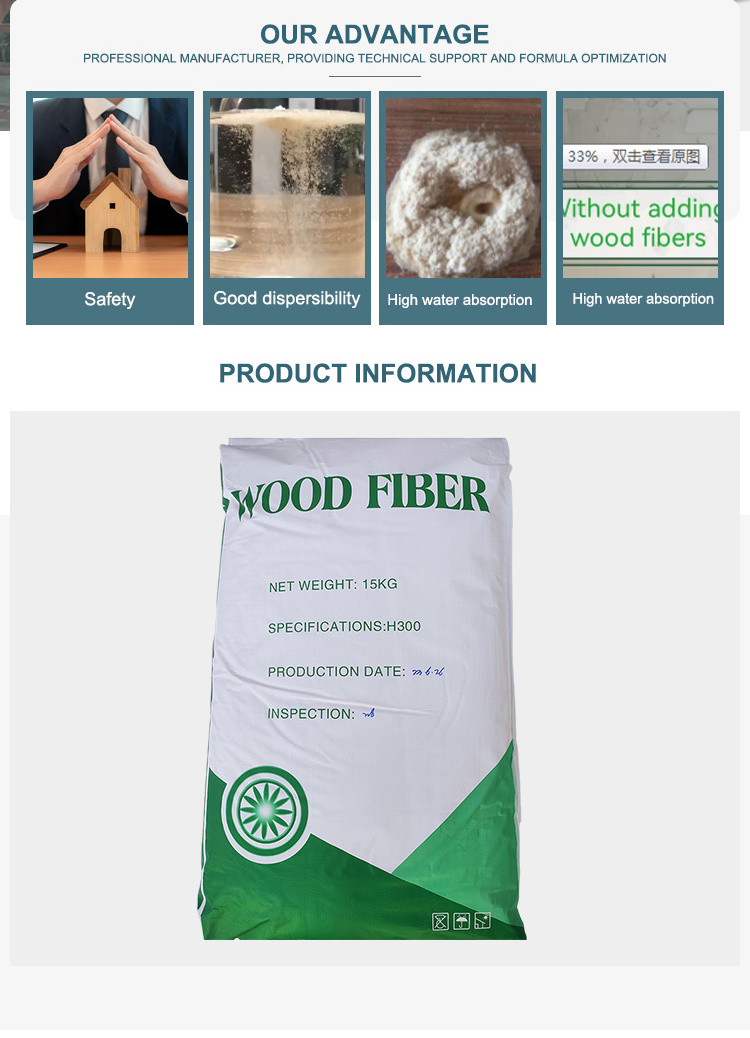

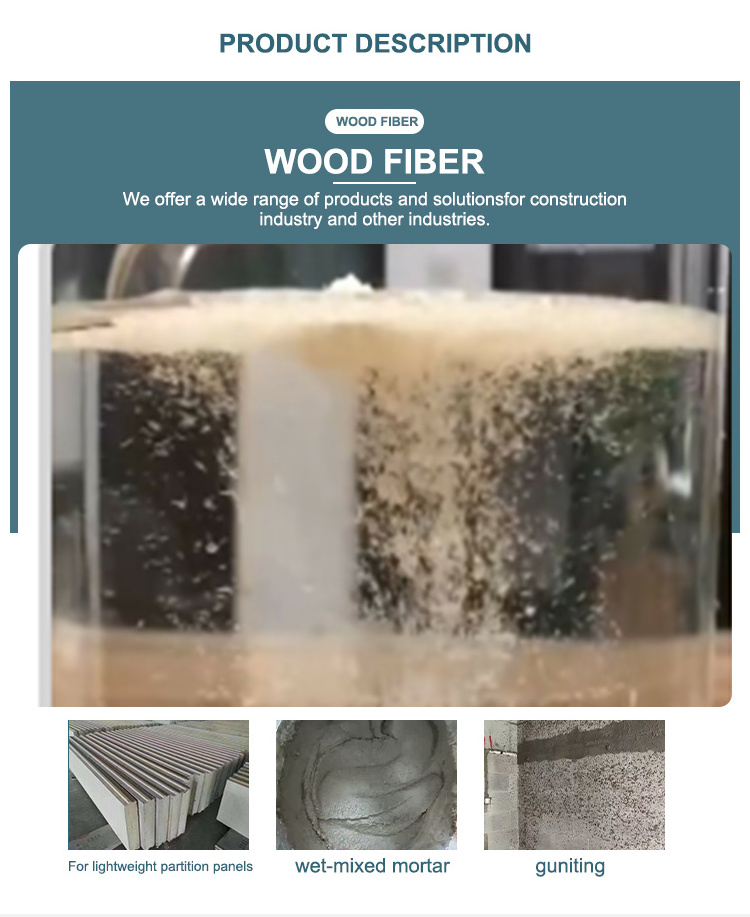

Crack resistance: The mechanical energy generated during the solidification or drying process is weakened by the fiber

reinforcement to prevent cracking. |

|

|

2

|

Low shrinkage: The biological size stability of wood fibers is good, and the mixture will not experience shrinkage settlement and

improve its crack resistance. |

|

|

3

|

Good liquid forced adsorption: Wooden fibers can absorb 5-6 times their own weight of water, and reduce the amount of cellulose

used appropriately |

|

|

4

|

Anti sagging: There will be no sagging during construction operations and drying processes. This allows thicker plastering to be

completed in one go, and even under high temperature conditions, wooden fibers have good thermal stability |

|

|

5

|

Easy to disperse: It is easy to mix with other materials, evenly dispersed, with good leveling, no sagging, and anti splashing

|

|

|

Some of the functions of lignin fibers, such as thickening, thickening, and water retention, are similar to those of cellulose.

But its unique water conductivity can fully and uniformly hydrate polymer mortar, improving the bonding strength and uniformity of strength on the surface of polymer mortar, effectively avoiding the phenomenon of cracking of polymer mortar due to uneven hydration. Thus becoming a polymer An indispensable additive for mortar (single component, dual component) |

|

|

|

1. Q: Are you manufacturer or trading company?

A: We are manufacturer and we have import and exportright.

2.Q: How can you promiseyour quality is good?A:

(1) Free sample provide for test.

(2) Before delivery, each batch will be tested strictly and retainedsample will bekeptinour stock to trace the variations of product quality.

3.Q: What is your payment?

A: L/C at sight or T/T 30% inadvance,70% balance againest the copy of B/L.

4.Q: Are you supply OEM?

A: We could offer OEM service according to customersrequirement.

5.Q: About the storage?

A: Stored in cool and dry place, avoid humidity and direct sunlight.

6.Q: Can you produceaccording to the sample?

A: Yes, we can produce according to the sample

|

|

|

|

|

||||

Hot Searches