All of our product packaging can ensure the safety of different roads and vehicles during transportation. Before the packaging is loaded and transported, it will undergo drop and anti-extrusion tests to ensure that the packaging is safe enough.

We can also customize the packaging and provide packaging safety testing according to customer requirements

- Product Details

- {{item.text}}

Quick Details

-

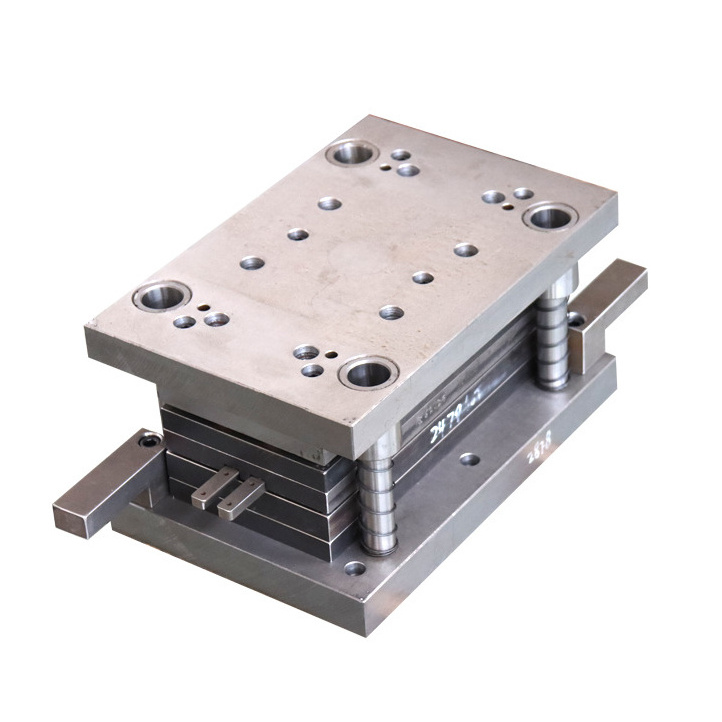

Model Number:

-

MSD006

-

Material:

-

SKD11, SKD 61, Cr12MOV, D2, SKH-9, RM56, ASP23 etc.

-

Product name:

-

Xilixin OEM

-

Size:

-

Customized Size\Client's Drawings

-

Usage:

-

Automotive,Electrical,Electronics,Energy,Home Appliance,Marine,Medical

-

Material Certificate:

-

ROHS REACH etc

-

Certification:

-

IATF 16949:2016 ISO9001

-

Tolerance:

-

0.01- +/-0.005mm

-

Design software:

-

AutoCAD, Solid works, PRO/E, UG

-

Mould Life:

-

100000-1000000

-

Package:

-

PE bags and carton wooden case for Die/mold, Customized

Quick Details

-

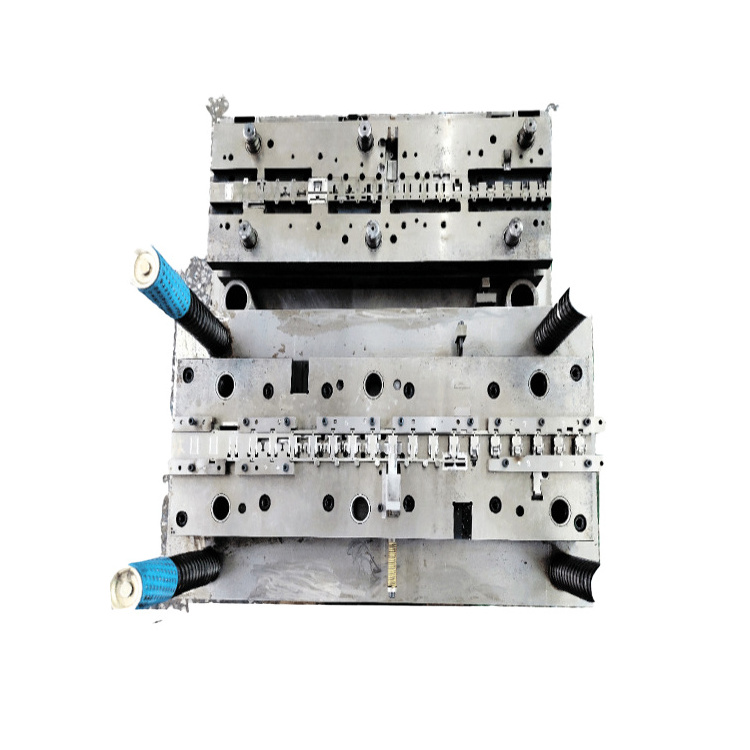

Shaping Mode:

-

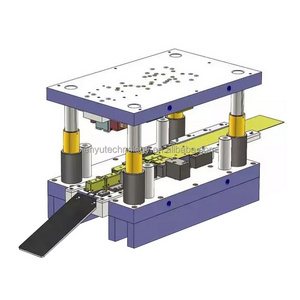

Punching Mold

-

Place of Origin:

-

Fujian, China

-

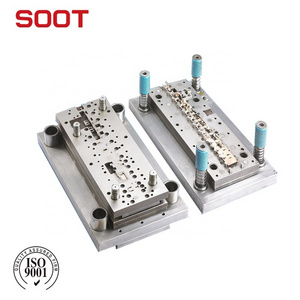

Brand Name:

-

Xulixin

-

Model Number:

-

MSD006

-

Material:

-

SKD11, SKD 61, Cr12MOV, D2, SKH-9, RM56, ASP23 etc.

-

Product name:

-

Xilixin OEM

-

Size:

-

Customized Size\Client's Drawings

-

Usage:

-

Automotive,Electrical,Electronics,Energy,Home Appliance,Marine,Medical

-

Material Certificate:

-

ROHS REACH etc

-

Certification:

-

IATF 16949:2016 ISO9001

-

Tolerance:

-

0.01- +/-0.005mm

-

Design software:

-

AutoCAD, Solid works, PRO/E, UG

-

Mould Life:

-

100000-1000000

-

Package:

-

PE bags and carton wooden case for Die/mold, Customized

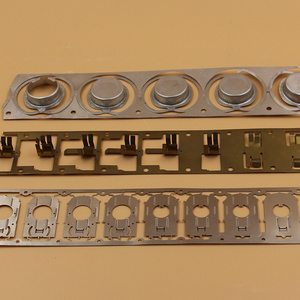

Product Description

|

Name

|

Xulixin Custom CNC Metal Fabrication CNC Turning CNC Milling Metal Parts Laser Cutting Sheet Metal Stamping blanks Parts

|

|

|

|

||||

|

Service

|

Sheet Metal Forming,Compound Die Stamping,Progressive Die Stamping,CNC Turning, CNC Milling, Laser Cutting, Bending, Spaning, Wire Cutting, Electric Discharge Machining (EDM), Injection Molding

|

|

|

|

||||

|

Materials

|

Aluminum: 2000 series,6000 series,7075,5052 etc

|

|

|

|

||||

|

|

Stainlesss steel: SUS303,SUS304,SS316,SS316L,17-4PH etc

|

|

|

|

||||

|

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo etc

|

|

|

|

||||

|

|

Brass: 260, C360,H59,H60,H62,H63,H65,H68,H70,Bronze,Copper

|

|

|

|

||||

|

|

Plastic: Acetal/POM/PA/Nylon/PC/PMMA /PVC/PU/Acrylic/ABS/PTFE/PEEK etc

|

|

|

|

||||

|

|

Titanium: GradeF1-F5

|

|

|

|

||||

|

Surface Treatment

|

Anodize, Bead blasted, Silk Screen, PVD Plating, Zinc/Nickl /Chrome/Titanium Plating, Brushing,Painting, Powder Coated,Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc

|

|

|

|

||||

|

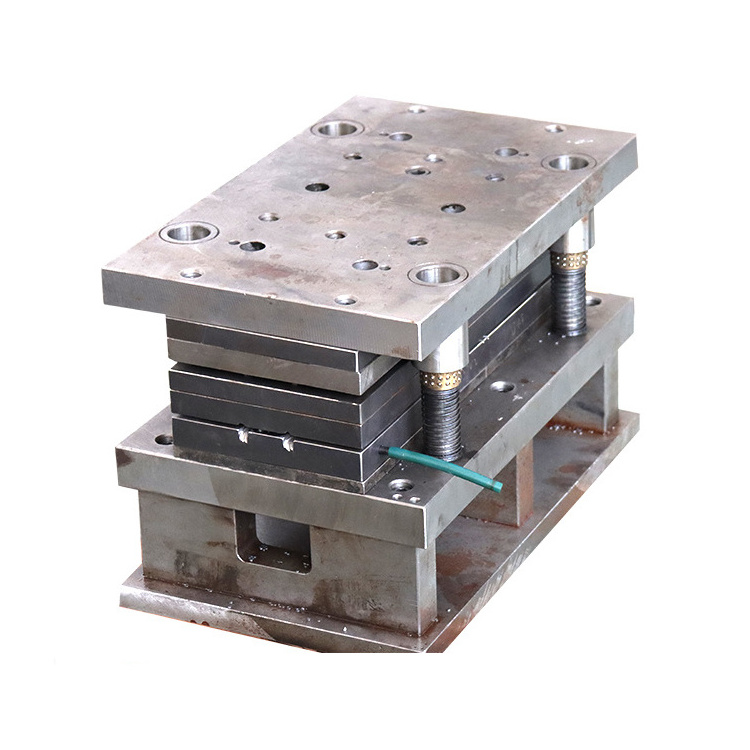

Tolerance

|

+/-0.002~+/-0.1mm

|

|

|

|

||||

|

Surface Roughness

|

Min Ra0.1~3.2

|

|

|

|

||||

|

Drawing Accepted

|

Stp,Step,Lgs,Xt,AutoCAD(DXF,DWG), PDF,or Samples

|

|

|

|

||||

|

Lead Time

|

1-14 days for samples,3-4 weeks for mass production

|

|

|

|

||||

|

Quality Control

|

ISO9001,TS16949:2016 ,ROHS,REACH,SGS

|

|

|

|

||||

|

Payment Terms

|

L/C,Wire Transfer,Trade Assurance, TT/Paypal/WestUnion

|

|

|

|

||||

|

Pre-shipment inspection PSI

is a part of our quality control method for checking the quality of goods. Pre SI is a vital part of quality control process. Pre Shipment inspection occurs when at least 80% of the products are manufactured. In which process a proportion of finished products is selected and a series of tests are performed to control functions,

sizes,demensions,measurements, packaging etc according to customer confirmed samples and technical drawing or documents.

PPAP(Production Part Approval Process)

documents can be provided upon request.

|

|

|

|

|

||||

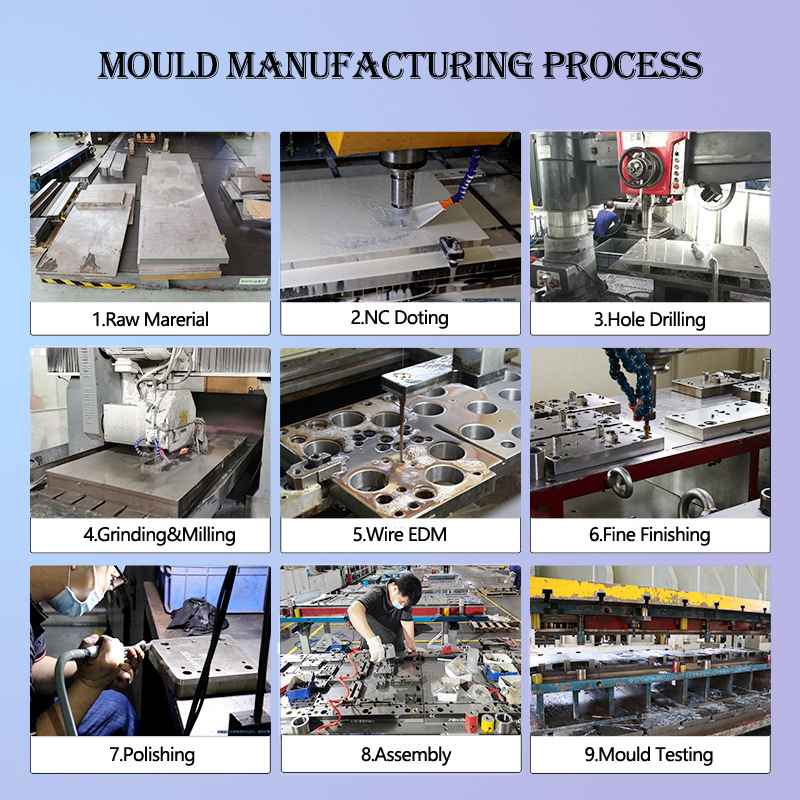

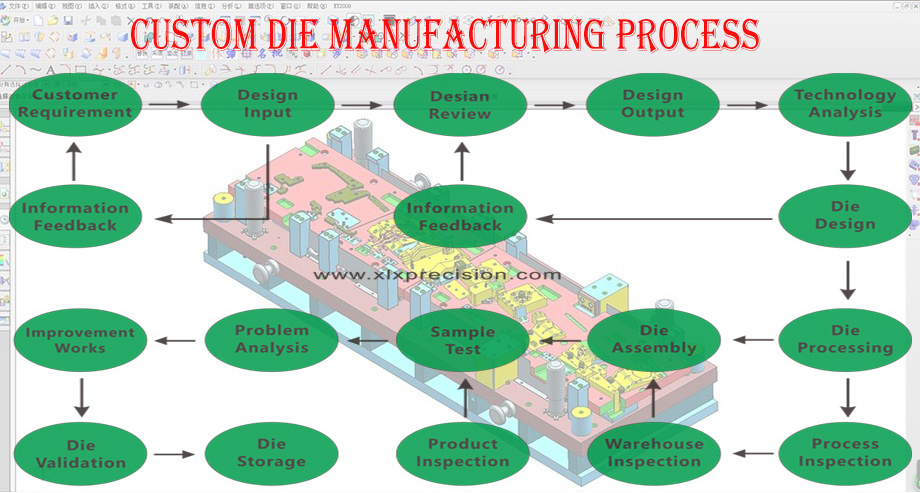

CNC Customize Order Processs

Product Usage

Company Introduction

Xulixin Precision Industry Co., Ltd

., established in 2000, is a professional manufacturer engaged in the design and production of precision CNC, precision stamping parts and precision stamping dies.

The company has passed ISO 9001 and IATF 16949:2016 quality system certification and has specialized in various precision metal processing for more than 20 years.

Our Business Philosophy:

1.Setting the standard for manufacturing excellence,

2.Integrity – we can’t build your business if we don’t have our own.

3.There’s No Substitute For It. And There Is No Substitute For Our Quality.

4.Ensure that the project is completed on time and within budget.

Packing&Shipping

Packing Method:

FAQ

1.Q: Who Are We?

A: We are factory with ISO 9001,IATF 16949 quality certification system in place, We produce all our products in-house with SGS Rosh Reach certificated materialS,so you can get better quality control and competitve price offering than others on the market.

We provide high-quality metal processing for international and domestic big brand manufacturers such as electrical appliances,electrical appliances and new energy vehicles etc

2.Q: What kind of service can you provide?

A: Our company (Xulixin Precision) can provide OEM sheet metal stamping and fabrication, CNC milling and turning,stamping die design and manufacturing service.

3.Q: What's kinds of information you need for a quote?

A: In order to quote for you earlier, please provide us the following information together with your inquiry.

a. Detailed drawings (STEP, CAD, SOLID Works, PROE, DXF and PDF)

b. Material requirement (SUS, SPCC, SECC, SGCC, Copper, AL, etc.)

c. Surface treatment (powder coating, sand blasting, planting, polishing, oxidization, brushing, etc.)

d. Quantity (per order/ per month/ annual)

e. Any special demands or requirements, such as packing, labels, delivery, etc.

4.Q: What if I don't have the required drawings or docuemnt information above?

A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

5.Q: What makes you different from others?

A:

A: We are factory with ISO 9001,IATF 16949 quality certification system in place, We produce all our products in-house with SGS Rosh Reach certificated materialS,so you can get better quality control and competitve price offering than others on the market.

We provide high-quality metal processing for international and domestic big brand manufacturers such as electrical appliances,electrical appliances and new energy vehicles etc

2.Q: What kind of service can you provide?

A: Our company (Xulixin Precision) can provide OEM sheet metal stamping and fabrication, CNC milling and turning,stamping die design and manufacturing service.

3.Q: What's kinds of information you need for a quote?

A: In order to quote for you earlier, please provide us the following information together with your inquiry.

a. Detailed drawings (STEP, CAD, SOLID Works, PROE, DXF and PDF)

b. Material requirement (SUS, SPCC, SECC, SGCC, Copper, AL, etc.)

c. Surface treatment (powder coating, sand blasting, planting, polishing, oxidization, brushing, etc.)

d. Quantity (per order/ per month/ annual)

e. Any special demands or requirements, such as packing, labels, delivery, etc.

4.Q: What if I don't have the required drawings or docuemnt information above?

A: Please send your sample to our factory, then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions (Thickness, Length, Height, Width), CAD or 3D file will be made for you if placed order.

5.Q: What makes you different from others?

A:

a.

We are an ISO 9001 and IATF 16949 certified manufacturer,Under these quality control system guideline as well as Our experienced technical personnel and skilled production operators,we can provide better quality products than others.

b.Fishish product quality inspection or Preshiment Inspection (PSI) reports available upon request.

c.Our quick manufacturing time and on-time delivery For Normal orders, we will promise to produce within 3 to 4 weeks.

d.24*7 customer service available,We will submit the quotation in 24 hours if getting detailed information during working days.As a factory and manufactuer, we have all the technicians to provide fastest response to all your technical inquiry.

6.Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with photos or videos which show the machining progress.We can provide production sample for testing approval before or during the mass products

7.Q: Can I have a trial order or samples only for several pieces?

A: As the product is customized and need to be produced, we will charge sample cost, ,we will refund the sample cost after you placed mass orders.

8.Q: Why there is tooling cost?

A: It’s mold cost. Indispensable production process. Only need to pay for first order, and we will bear maintenance cost of mold damage.

9.Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance.

Payment>=1000USD, 40% T/T in advance, balance before shipment.

10.Q: What’s your after-sale service?

A: If there is quality problem, please provide photos or test report, we will replace defective goods or return funds immediately..

c.Our quick manufacturing time and on-time delivery For Normal orders, we will promise to produce within 3 to 4 weeks.

d.24*7 customer service available,We will submit the quotation in 24 hours if getting detailed information during working days.As a factory and manufactuer, we have all the technicians to provide fastest response to all your technical inquiry.

6.Q: Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with photos or videos which show the machining progress.We can provide production sample for testing approval before or during the mass products

7.Q: Can I have a trial order or samples only for several pieces?

A: As the product is customized and need to be produced, we will charge sample cost, ,we will refund the sample cost after you placed mass orders.

8.Q: Why there is tooling cost?

A: It’s mold cost. Indispensable production process. Only need to pay for first order, and we will bear maintenance cost of mold damage.

9.Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance.

Payment>=1000USD, 40% T/T in advance, balance before shipment.

10.Q: What’s your after-sale service?

A: If there is quality problem, please provide photos or test report, we will replace defective goods or return funds immediately..

Related Products

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches