- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CNCM

-

Model Number:

-

CNMC 101

-

Type:

-

liquid foam material

-

Hydroxyl Value:

-

200-300mgKOH/g

-

Specific gravity (20 ℃:

-

1.12-1.20g/ml

-

Density:

-

21lb/ft2(33.6kg/m3)_

-

Initial thermal resistance:

-

7.4ft2h°F/BTU(1.3KM2/W)

-

Storage Temperature:

-

10-25 ℃

-

Dynamic Viscosity (25 ℃):

-

100-200mpa.s

-

Isocyanate:

-

100-105

-

Storage Stability:

-

6 month

-

DJD-105 blend polyols:

-

100

-

color:

-

White

Quick Details

-

Other Names:

-

Polyurethane Foam

-

MF:

-

(C10H8N2O2.C6H14O3)x

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CNCM

-

Model Number:

-

CNMC 101

-

Type:

-

liquid foam material

-

Hydroxyl Value:

-

200-300mgKOH/g

-

Specific gravity (20 ℃:

-

1.12-1.20g/ml

-

Density:

-

21lb/ft2(33.6kg/m3)_

-

Initial thermal resistance:

-

7.4ft2h°F/BTU(1.3KM2/W)

-

Storage Temperature:

-

10-25 ℃

-

Dynamic Viscosity (25 ℃):

-

100-200mpa.s

-

Isocyanate:

-

100-105

-

Storage Stability:

-

6 month

-

DJD-105 blend polyols:

-

100

-

color:

-

White

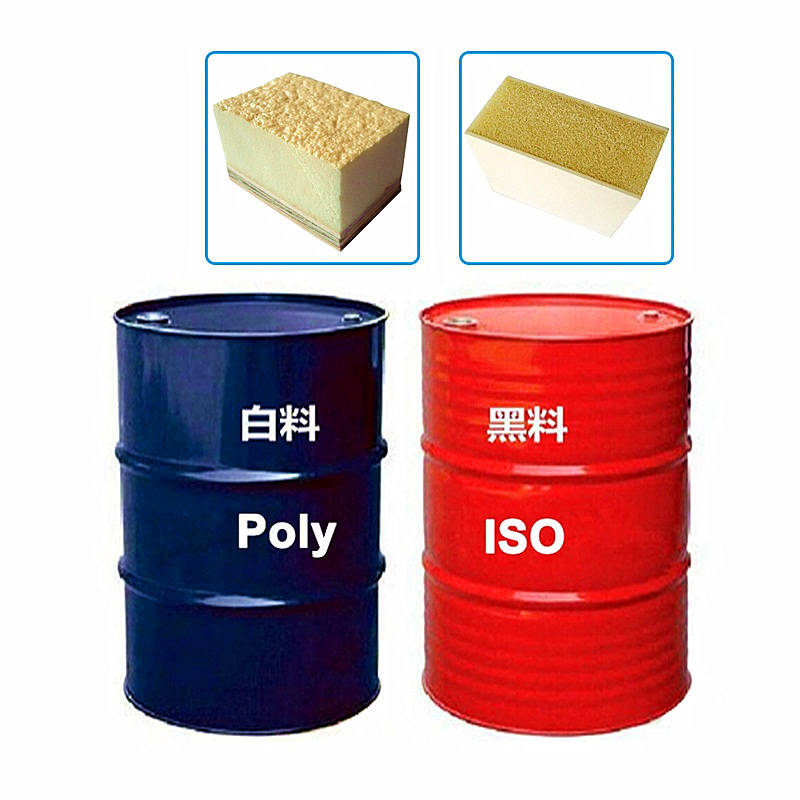

Closed Cell Two Component Polyurethane

CNMC101 is a two component, colsed cell,spray applied rigid polyurethane foam system.This product uses recycled plastic matericals,rapidly renewable soy,and the blowing agent has zeeroozone depleting penitential,CNMC 101 complies with intent of international code Council's residential and commercial building codes and is commonly used as a thermal insulation,air barrier,vapor retarder and water resistive barrier in above grade,interior and exterior applications.

Physical Properties

|

Appearance Hydroxyl Value mgKOH/g Dynamic Viscosity (25 ℃ ) mpa.s Specific gravity (20 ℃ ) g/ml Storage Temperature ℃ Storage Stability month |

Pale yellow to brown viscous liquid 200 -3 0 0 100-200 1.12-1.20 10-25 6 |

Recommended Ratio

|

|

pbw |

|

D JD-105 blend polyols Isocyanate |

100 100-105 |

Reactivity Characteristics

(The temperature of the system is 20 ℃ ,and the exact value varied depending on processing condition)

|

Cream T ime s G el T ime s |

3-5 6-10 |

Foam Performances

|

items |

Test Method |

Index |

|

Spray Density Closed-cell Rate Initial Thermal Conductivity( 15 ℃ ) Compressive Strength Adhesive Strength Elongation at break Dimentional Stability 24h -20 ℃ 24h 70 ℃ Water Absorption Oxygen Index |

GB 6343 GB 10799 GB 3399 GB/T8813 GB/T16777 GB/T9641 GB/T8811

GB 8810 GB 8624 |

> 40 kg/m 3 ≥90% ≤24mW/(m.K) ≥150kPa ≥120kPa ≥10% ≤1% ≤1.5% ≤3% ≥26 |