- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380v

-

Materials::

-

304 Stainless steel

-

Automatic::

-

PLC Controlled

-

Cylinder::

-

YSC Brand

-

Bearing::

-

NSK Brand from Japan

-

Gearbox::

-

S E W Brand from Germany

-

Transducer::

-

SIEMENS Brand

-

Motor::

-

SIEMENS Brand

-

Quality certificate::

-

ISO, CE certificate

-

Steel Band::

-

SANDVIC Brand

-

Burner:

-

Weishaupt

-

Marketing Type:

-

New Product 2021

-

Power:

-

15KW

-

Certification:

-

IOS, CE certificate

Quick Details

-

Brand Name:

-

SINOBAKE

-

Dimension(L*W*H):

-

MM

-

Weight:

-

100 KG

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380v

-

Materials::

-

304 Stainless steel

-

Automatic::

-

PLC Controlled

-

Cylinder::

-

YSC Brand

-

Bearing::

-

NSK Brand from Japan

-

Gearbox::

-

S E W Brand from Germany

-

Transducer::

-

SIEMENS Brand

-

Motor::

-

SIEMENS Brand

-

Quality certificate::

-

ISO, CE certificate

-

Steel Band::

-

SANDVIC Brand

-

Burner:

-

Weishaupt

-

Marketing Type:

-

New Product 2021

-

Power:

-

15KW

-

Certification:

-

IOS, CE certificate

The price in the this table is only for reference. The exact price needs to be decided by the real solution.

Product Description

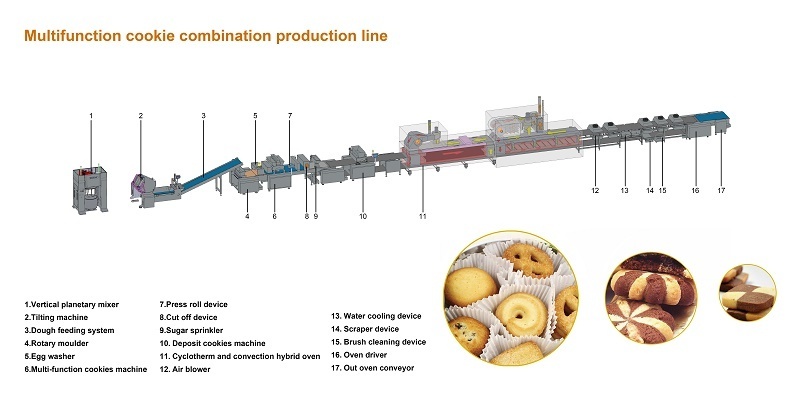

Newly Industrial Complete Multi-function Chocolate Cookie Production Line Dropping Depositor Fortune Cookie Making Machine

In addition to soft biscuit,soda biscuit,crackers, there is an important type of biscuit product is cookies. The cookies can be classified as wire cut cookies,depositor cookies,two-color cookies,tricolor cookies etc., with different equipment can increase the diversity of products and improve product taste.

In addition to soft biscuit,soda biscuit,crackers, there is an important type of biscuit product is cookies. The cookies can be classified as wire cut cookies,depositor cookies,two-color cookies,tricolor cookies etc., with different equipment can increase the diversity of products and improve product taste.

FEATURES FOR COOKIE MACHINE

1.Fully servo motors controlled

2.Easy to operate with touch screen

3.Easy to clean and discharge for all dough flow channel mold components

4.Gear pump control the each cookie weight accurately

5.One machine can make single color,dual colors and three colors cookies.

A WHOLE COOKIE LINE USUALLY INCLUDES FOLLOWING MACHINE

1.Vertical dough mixer(300L)

2.Tilting Machine

3.Auto dough feeding system

4.Cookie machine--one color cookie machine,two colors cookie machine,three colors cookie machine

5.Electric oven(gas,diesel ovens are available. The length depends on the capacity you need)

6.Out oven machine

7.Cooling conveyor

8.Penny stacker

9.Packing table

Enter oven machine,sugar&salt sprinkler, are suggested to added, if your space is available.

The following description of each machine are based on standard one:

3.Auto dough feeding system

4.Cookie machine--one color cookie machine,two colors cookie machine,three colors cookie machine

5.Electric oven(gas,diesel ovens are available. The length depends on the capacity you need)

6.Out oven machine

7.Cooling conveyor

8.Penny stacker

9.Packing table

Enter oven machine,sugar&salt sprinkler, are suggested to added, if your space is available.

The following description of each machine are based on standard one:

Dough mixer

It is for mixing soft biscuit and cookie dough, which contains more oil &fat.

300L/time,

Three vertical blades

Tilting machine

Tilting machine is used to pour the dough from trolley into the hopper of the dough feeding system. We have

500kgs/time and 1000kgs/time for your choice.

We can also provide

Hydraulic tilting machine.

Auto dough feeding system

Auto Dough feeding system is used for breaking the dough into small pieces and sending them to the cookie machine.

Cookie Machine

One color,two colors and three colors cookie machine can be provided. And we have wire cut cookie machine,blade cutting cookie machine,depositor machine, extruded cookie machine, en-crusted cookie machine.

Enter oven machine

Enter Oven Machine is used to send the formed biscuits into the oven, recycling the sugar, salt or reject biscuits.

Oven drive and tension system

mainly provide motive power to oven belt,drive the mesh belt,the mesh belt can be tensioned manually, pneumatic offset adjustment,the belt has brush cleaning device.

For the steel band oven, the oil device is suggested.

Tunnel oven

It is the baking equipment of the biscuit line,baking biscuit by indirect thermal radiation, making biscuit with fine color and flavour. For soft biscuits and cookies, convection oven is suggested. The oven heating source can be gas, electricity, diesel.

Out oven machine

it is used for conveying baked biscuit out of oven smoothly.

Cooling part

After out oven machine, 180 degree plane turning conveyor or 90 degree plane turning conveyor,cooling conveyor,stacker,packing table are needed.

Materials:

1. Q235 carbon steel sideboard, thickness of 28mm.

2. chromed surface, hardness of HRC58-62

3. frame board of Q235 carton steel, thickness of 15mm,

4. chromed surface, hardness of HRC58-62

5. Supporting plate of SUS304.

6. 1.5mm SUS304 cover

7. SEW motor and speed reducer, frequency control of speed.

8. Digital display of speed and space

9. No cornerns for cleaning, safe and healthy.

10. Emergency switch intalled

11. Perfect cable arrangement with aluminium alloy cable boxes.

12. SIEMENS control apparatus 20. NSK bearing

Contact us

Send your email, get the best quotation:

Atom Lin

whatsApp/wechat/Tel:0086 137 9464 0490

Email:atom@sinobake.net

Kunzhou Industrial Zone, Beijiao, Shunde, Foshan City,

Guangdong Province, China

Finished products

Company Introduction

SINOBAKE

(Guangdong Shunde Huaji Machinery Industrial Co.,Ltd) has been supplying equipments and process technology to biscuit industry since 1994. We have been exporting our production lines and machines all over the world for more than100 countries. Thanks for the well professional staffs and engineers, with their experience and know-how, we can meet your requirements when supplying either single machines or complete production lines and the turn-key projects. Our company operates the production and assembly in strict compliance with ISO 9001 and CE standards to provide reliable and safety products for customers all over the world.

SINOBAKE welcomes you to be a partnership to find the best solution in producing your biscuit products. Join and profit from our international experience and the knowledge we gained over the past two decades. Customer specific innovations in our Technology Department are combined with the application of the latest technology in building flexible production lines and turn-key solutions. We believe that SINOBAKE Workgroup will inspire you to come to the profitable and practical solution for your challenges.

SINOBAKE welcomes you to be a partnership to find the best solution in producing your biscuit products. Join and profit from our international experience and the knowledge we gained over the past two decades. Customer specific innovations in our Technology Department are combined with the application of the latest technology in building flexible production lines and turn-key solutions. We believe that SINOBAKE Workgroup will inspire you to come to the profitable and practical solution for your challenges.

We sincerely hope to have a fruitful partnership with you.

Our Services & Strength

(1)We have more than 27 year's experence in manufacturing food processing machine.

(2)Professional technical team,Company own's reasearch and development team ,Top quality ,Reasonable price,Timely delivery and first-class service.

(2)Professional technical team,Company own's reasearch and development team ,Top quality ,Reasonable price,Timely delivery and first-class service.

Certifications

Advantages

1.High quality:Using high quality material,establishing a strict quality control system,and assigning specific persons in charge of each part of production, from raw material purchase to assembly.

2:Professional R&D center:with more than 26 years working experience in biscuits and cookies machine industry.

2:Professional R&D center:with more than 26 years working experience in biscuits and cookies machine industry.

3.Cooperating with China famous food company,we have rich experiences on

machine and technical.

4.Good pre-sales&after sales services, provide complete production line from A to Z.

machine and technical.

4.Good pre-sales&after sales services, provide complete production line from A to Z.

FAQ

1.Are you manufacturer?

5.How is the installation and commissioning?

Supervision of Installation and commissioning work will be carried out by technical staff together with the technical staff from SINOBAKE GROUP LTD.

Yes, we are professional biscuit and cookie machinery manufacturer. We have professional engineers and manufacturing technologist to help you make a suitable solution.

2.Why SINOBAKE can do better than other factories?

Our company specialize in biscuit and cookie machine for 27 years, we start base on the recipe and Europe technology, at the same time, we develop and improve our machinery year by year from our partner and long term relationship customer. Sinobake machine already supply to more than 100 countries, as well as leading in china local market. We provide the best service for all of clients and have good relationship. we looking forward to start new long term relationship with you.

2.Why SINOBAKE can do better than other factories?

Our company specialize in biscuit and cookie machine for 27 years, we start base on the recipe and Europe technology, at the same time, we develop and improve our machinery year by year from our partner and long term relationship customer. Sinobake machine already supply to more than 100 countries, as well as leading in china local market. We provide the best service for all of clients and have good relationship. we looking forward to start new long term relationship with you.

3.How is the package?

We clean the machine first then pack almost all with PE foam and outside with plywood suitable for safety transportation.

4.How is the delivery time?

It depends on the line you purchased. the delivery time is within 30-120 working days. Pls contact us to know the detailed time.

We clean the machine first then pack almost all with PE foam and outside with plywood suitable for safety transportation.

4.How is the delivery time?

It depends on the line you purchased. the delivery time is within 30-120 working days. Pls contact us to know the detailed time.

5.How is the installation and commissioning?

Supervision of Installation and commissioning work will be carried out by technical staff together with the technical staff from SINOBAKE GROUP LTD.

Hot Searches