- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Zhongdi

-

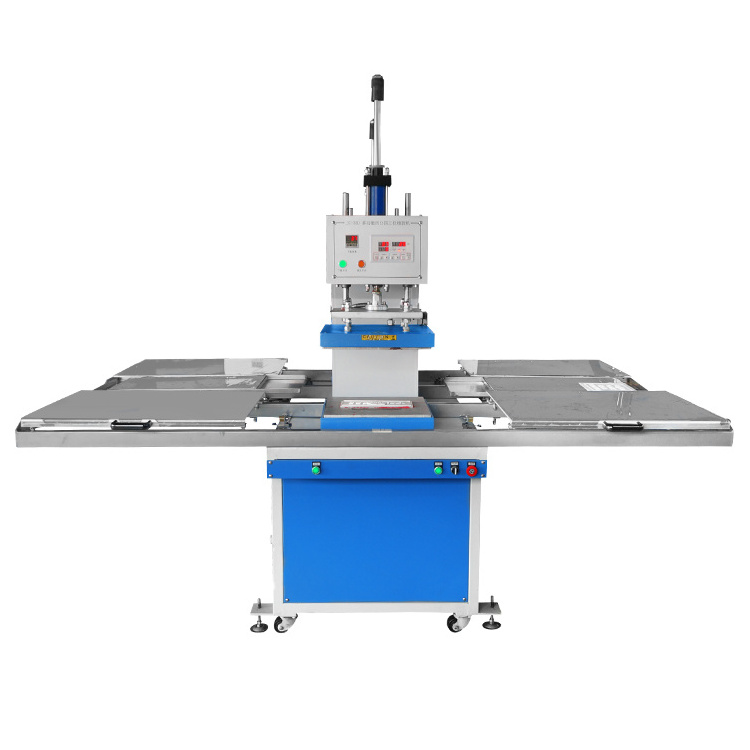

Dimensions(L*W*H):

-

180*106*218

-

Weight:

-

970 KG

-

Product name:

-

embossing machines

-

Application:

-

embossing fabric clothes

-

Function:

-

Multi Function

-

Keywords:

-

four station embossing

-

Usage on:

-

embossing dispensing machines

-

Feature:

-

multi-functional machines

-

Advantage:

-

Competitive Factory-direct

-

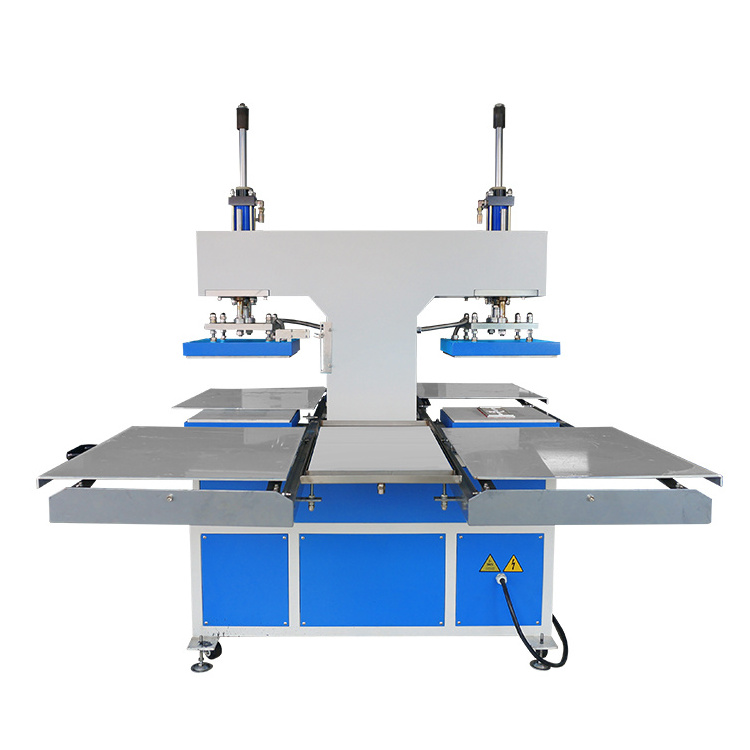

Operation:

-

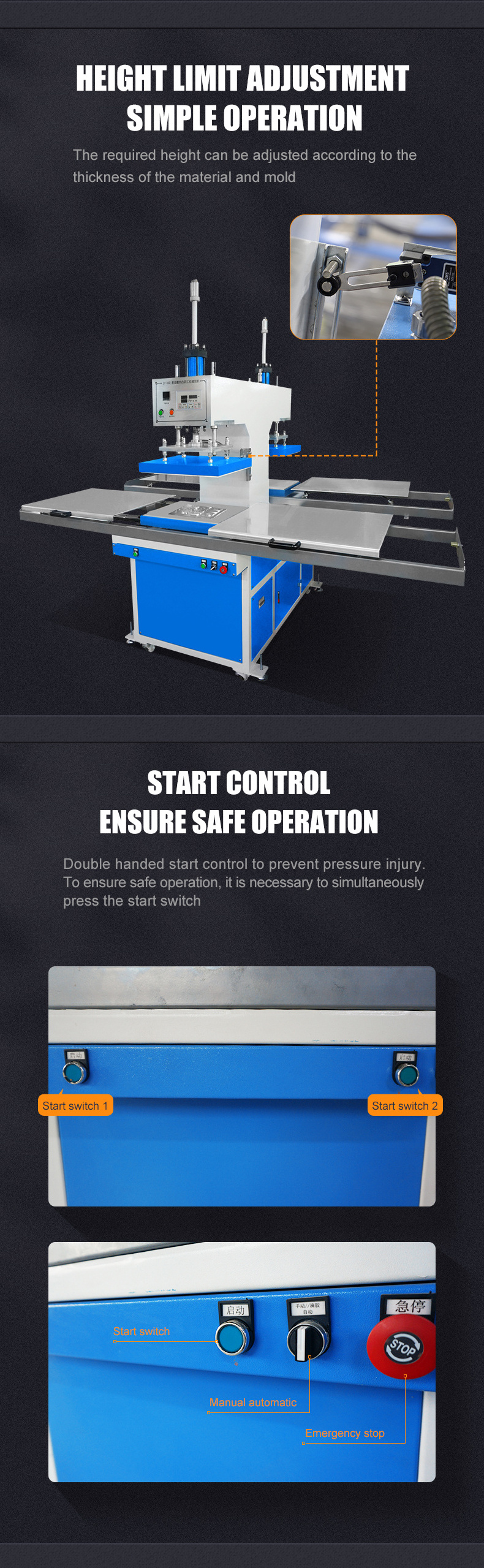

hydraulic double emboss head

-

After-sales Service Provided:

-

Online Support Video Technical Support

-

Service:

-

one year warrenty

Quick Details

-

Condition:

-

New

-

Plate Type:

-

Flatbed Printer

-

Color & Page:

-

Multicolor

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Zhongdi

-

Dimensions(L*W*H):

-

180*106*218

-

Weight:

-

970 KG

-

Product name:

-

embossing machines

-

Application:

-

embossing fabric clothes

-

Function:

-

Multi Function

-

Keywords:

-

four station embossing

-

Usage on:

-

embossing dispensing machines

-

Feature:

-

multi-functional machines

-

Advantage:

-

Competitive Factory-direct

-

Operation:

-

hydraulic double emboss head

-

After-sales Service Provided:

-

Online Support Video Technical Support

-

Service:

-

one year warrenty

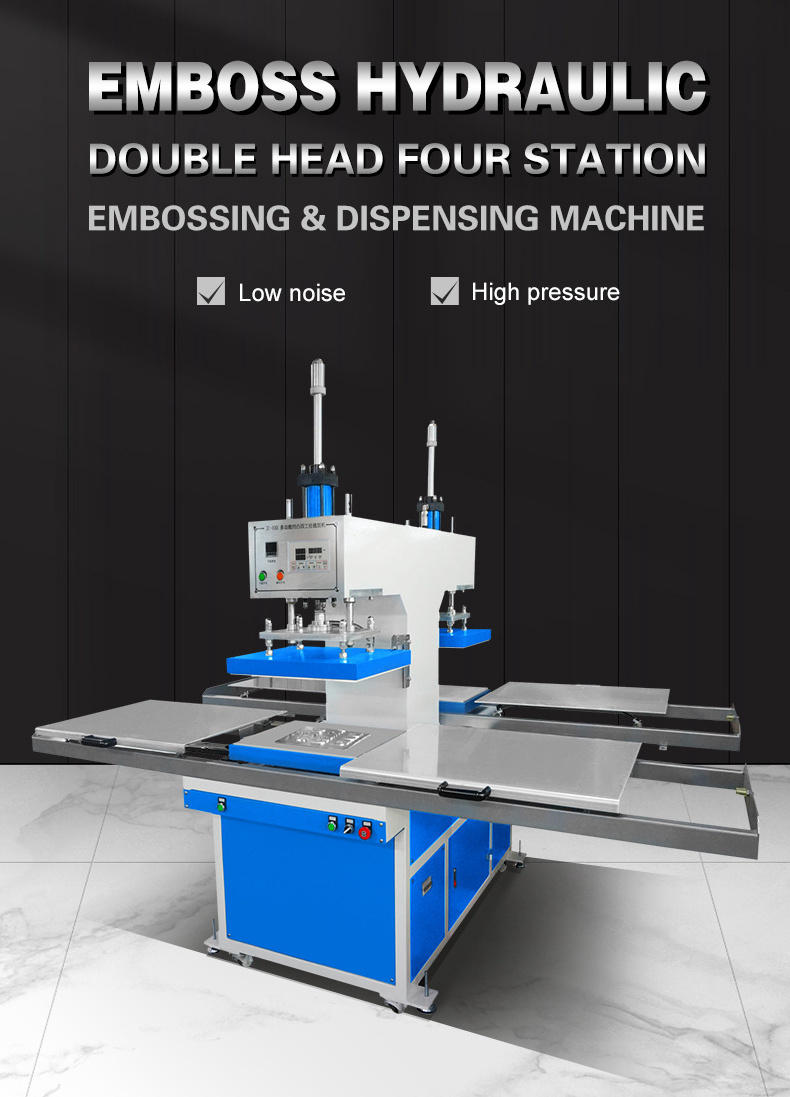

Factory hot sale 40 x 60 cm multi-functional four station hot press clothes dual embossing machines for t-shirts embossing and dispensing oil pressure sliding

Application

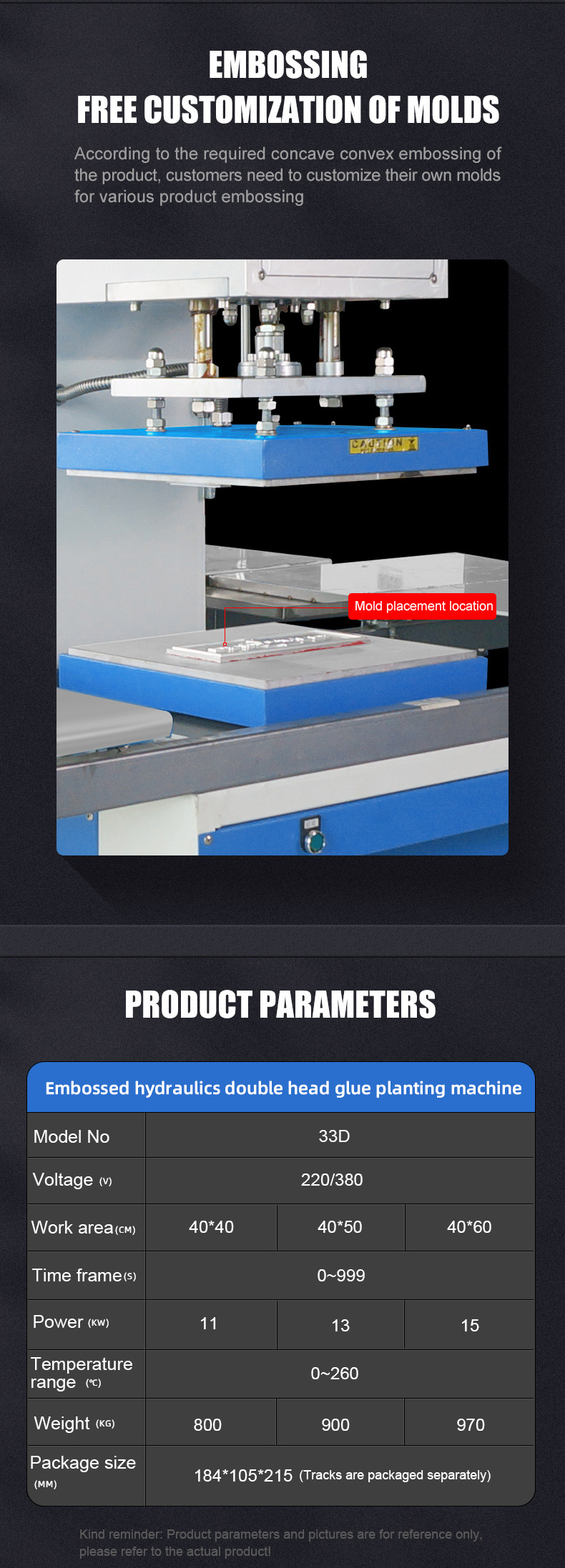

Craft,polyester,flexible(soft) glue,polystyrene,Epoxy,transparent

Specification

1) Saving time when you designated the mould

2) Wide application:varied of dispensing products are acceptable.

3) High productivity,high practicability, high performance price ration.

Process of Embossing

First,set the position for moulds you will stick to the heatng platen.Second,pre-heat the machine.Wait for it to reach up about 220-235℃.And set time about 8 seconds. Third,let the heating platen press down.After 8sec.,it will auto release.Finally you can use the machine to do the embossing.But before doing embossing,you need to know there is a step that scrape the silicone(similar to screen printing)on the back side of fabirc.

Hope the above operataion steps can help you understand.

Process of Silicone

First,Pre-heat the machine.Set time about 180-220℃.

Second,mix color liquid,curing agent and the silicone together in proportion.Third,put them into the vacuum machine to let the air go out.Fourth,scrape the items on the mould.Finally,you can press it.

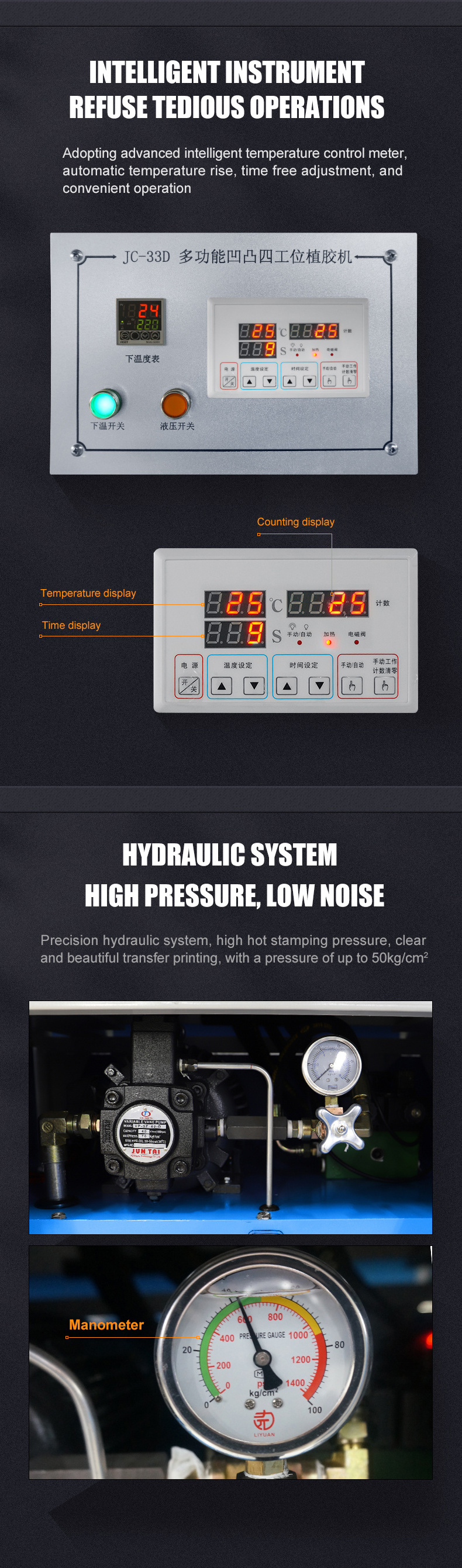

Technical parameters

| Print area | 40*60cm |

| Voltage | 220/380V |

| Power | 15KW |

| Temperature range | 0-399℃ |

| Timer control | 0-999sec. |

| Weight | 970kg |

| Packing size(excluding the track) | 180*125*220cm |

| Warranty time | 1 year |

1. Q: What is the purpose of a heat press?

A heat press is the machine that presses a transfer onto an

transferable

substrate. Using high temperatures and heavy pressures for a certain amount of time, the transfer is permanently embedded into the product.

Heat presses are recommended for professional and satisfying results simply because standard laminating devices and home hand irons can not get even near the temperatures required for a reliable transfer. Standard transfers require anywhere from 180 to 220 degrees demand serious force in pressing. These temperatures and pressures are simply not possible with other heated devices.

2. Q: How to choose the right heat press?

As with any equipment, there are many factors to take into consideration when choosing a heat press machine.

The most important thing to look for in a heat press is its ability to provide consistently even temperatures across the platen. This will prevent cold spots from developing and ensure consistent application of heat transfer materials. Proper application temperature is also critical in producing quality garments, making accurate temperature controls an essential feature.

3. Q: What items can be heat pressed?

The following are some of the far more common items often heat pressed. The list by no means ends here.

T-Shirts, Caps, Ceramic Plates, Ceramic Tiles, Mugs, Mouse Pads, Paper Memo Cubes, Tote Bags, Jigsaw Puzzles, Lettering, Numbers, Rhinestones/Crystals, Wood / Metals Other Misc. Fabrics & Materials.

4.Q: What is a transfer made up of ?

A transfer is made up of a carrier paper and inks. When heated to a certain temperature and pressed with a significant amount of pressure for a certain amount of time, the transfer inks are passed over to the

transferable

material. Some inks are adhered and embedded to the surface of the material, while others (namely, sublimation) permeate the coating of the material.

5.Q: What are the different uses for a heat press?

The variety of uses for a heat press include the application of various types of heat applied materials (listed below), curing of Direct to Garment (DTG) printing, smoothing of embroidery after sewing, and dye sublimation.

6.Q: What will be need if doing heat transfer?

You will need a heat transfer machine(kinds of heat press for choices, if transfer t-shirt, you will need a flat heat press, if transfer cap, you would need a cap press or our combo press etc.) printer, CISS, ink, transfer paper.

7.Q: What kind of ink do I need?

This depends on the material you want doing heat transfer.Ceramic products like tile or mug,you have to use sublimation ink,but if like polyester T-shirt,mouse pad,you can use dye or pigment ink.

8. Q: What kind of paper do I need?

For sublimation there are different papers developed for different substrates.Mouse pad,bags,fabrics are best transferred using our special transfer paper.When transferring items such as ceramics,glass,you can use normal inkjet paper.