- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380,220,240

-

Dimension(L*W*H):

-

according to model

-

Marketing Type:

-

discount

-

Weight (KG):

-

68000 kg

-

Keywords:

-

Brick Making Mahcine

-

Raw material:

-

sand, fly ash, gypsum, cement, lime

-

designing cost:

-

free

-

motor brand:

-

Simens Power

-

Application:

-

House Building, construction

-

After Warranty Service:

-

Video/Online support/Spare parts

-

Local Service Location:

-

Indonesia/Russia/Thailand

-

Local Service Location2:

-

Egypt/Philippines/Viet Nam

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine

-

Brick Raw Material:

-

Cement, gypsum, sand, fly ash, lime

-

Production Capacity (Pieces/8 hours):

-

20,000M3 per year

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

380,220,240

-

Dimension(L*W*H):

-

according to model

-

Marketing Type:

-

discount

-

Weight (KG):

-

68000 kg

-

Keywords:

-

Brick Making Mahcine

-

Raw material:

-

sand, fly ash, gypsum, cement, lime

-

designing cost:

-

free

-

motor brand:

-

Simens Power

-

Application:

-

House Building, construction

-

After Warranty Service:

-

Video/Online support/Spare parts

-

Local Service Location:

-

Indonesia/Russia/Thailand

-

Local Service Location2:

-

Egypt/Philippines/Viet Nam

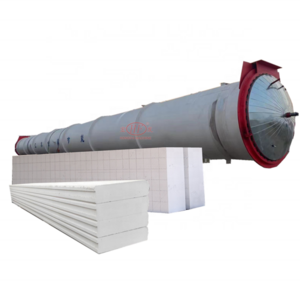

10000~600000m3 aac block and panel production line

Light weight aac autoclave aerated concrete block brick making machine line

Main raw materials of AAC are siliceous material (sand, fly ash and Silicon tailings) and Calcium materials (lime and cement) mixed with foaming agent (aluminum powder). It is the product of light porous silicate through the following processes: batching, mixing, pouring, hardening, cutting, autoclaving and curing etc. Because of large amount of well-distributed tiny pores after foaming, it is named autoclaved aerated concrete.

AAC Classification :

In general, it can be classified according to the types of raw materials, manufacture process and functions. Based on the shape of AAC products, it can be divided into: AAC blocks and AAC panels. It is a revolutionary material offering an unique combination of high durability and strength, low weight, excellent heat insulation, fire resistant, noise absorption, unprecedented build ability and superior ecological green features. In China, AAC is one of the light wall materials which was popularized and applied at the earliest and the most widely.

1. raw material preparation:

Using reversal crane carry the mould and block to demould on cutting cart. The cutting cart will take the block to level cutting machine,vertical cutting ,two sides cutting,and remove the top waste material.

5. Autoclaved

Finished cutting using semi-product crane carry to the front of autoclave grouped,hoisting machine or dragger will drag steam trolley into autoclave to steam,it need 10-12 hours.

6. Finished block dealing

7. Package

Using finished block carry hanger clamp the finished product to package line on wooden pallets,after package, then by forklift transport the finished products to piled yard according to specifications to stack.

Main Equipments in AAC Production Line:

The normal production capacity:

|

Annual Capacity ( 300days ) |

Power |

Daily Capacity |

Cycle Time |

No. of Autoclaves |

plant area (m2) |

|

50,000m³/year |

400KW |

166 m³/day |

8 hours |

2 |

2000 |

|

100,000m³/year |

500KW |

333m³/day |

8 hours |

4 |

2000 |

|

150,000m³/year |

630KW |

500m³/day |

8 hours |

6 |

2500 |

|

200,000m³/year |

720KW |

666m³/day |

8 hours |

8 |

3000 |

|

300,000m³/year |

1186KW |

1000m³/day |

8 hours |

6(D2.85*32.5) |

3500 |