- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

Yugong

-

Voltage:

-

220V/240V/380V/440V

-

Dimension(L*W*H):

-

8000*1500*800mm

-

Weight:

-

2500 kg, 2500KGS

-

Product name:

-

roll forming machine

-

Model:

-

YG-200

-

Raw material:

-

Steel Coil GI PPGI

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Application:

-

Building Construction

-

Roller material:

-

45#steel Chrome Plated

-

Thickness:

-

0.3-0.8mm Thickness

-

Keywords:

-

Colored Steel Roof Making Machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

Yugong

-

Voltage:

-

220V/240V/380V/440V

-

Dimension(L*W*H):

-

8000*1500*800mm

-

Weight:

-

2500 kg, 2500KGS

-

Product name:

-

roll forming machine

-

Model:

-

YG-200

-

Raw material:

-

Steel Coil GI PPGI

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Application:

-

Building Construction

-

Roller material:

-

45#steel Chrome Plated

-

Thickness:

-

0.3-0.8mm Thickness

-

Keywords:

-

Colored Steel Roof Making Machine

Product Description

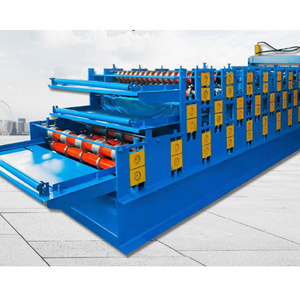

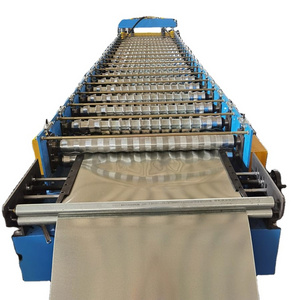

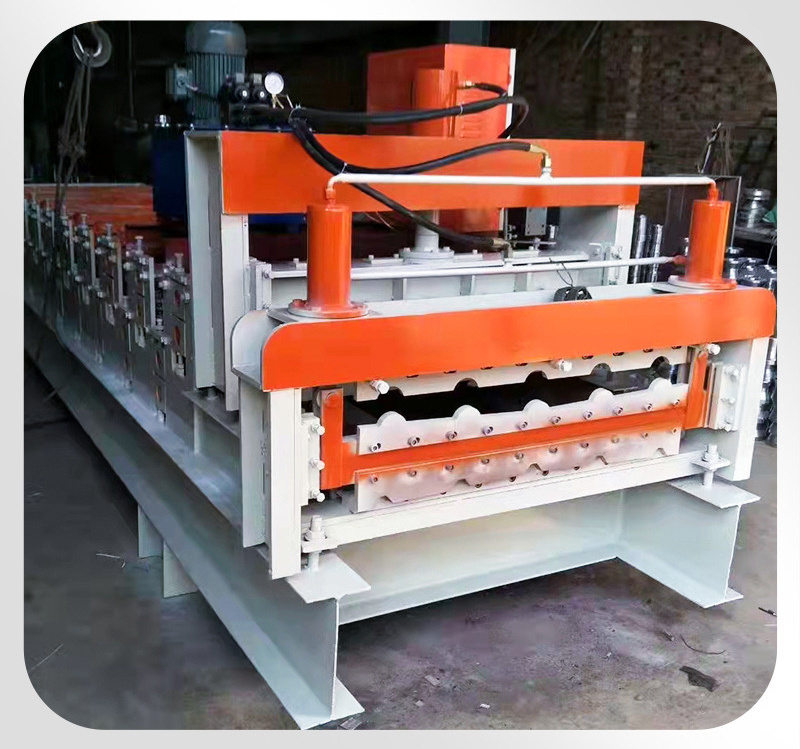

Factory Price Yugong Brand roll forming machine for Sale

Machine Description

Features

LARGE CNC MILLING MACHINE

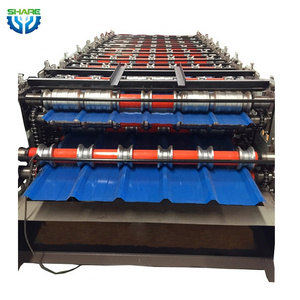

Combined double layer building material machinery steel tile roofing sheet roll forming machine a unique plant in Henan Province.It directly mills the entire frame. The milling machine can make the machine's large surface smoother and the machine is more perfect. Combined double layer building material machinery steel tile roofing sheet roll forming machine

SHOT BLASTING MACHINE

Combined double layer building material machinery steel tile roofing sheet roll forming machine can handle the entire machine frame or parts,making the rusty surface clean and smooth The surface of the product increases adhesion. Combined double layer building material machinery steel tile roofing sheet roll forming machine

NEW CNC MILLING

Combined double layer building material machinery steel tile roofing sheet roll forming machine make the backboard of purlin machine, also make the holes on backboard. This milling machine can milling the backboard more level, hole place is more precious. This can make the roller more level after installing,and then the purlin will be more straight.

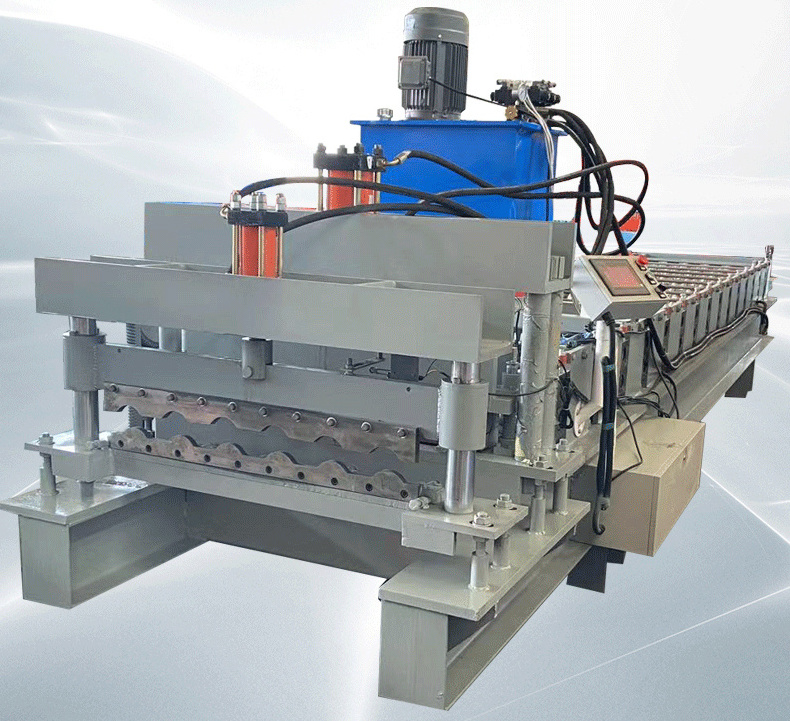

Specification

|

Model

|

YG-550

|

|

Production speed

|

Max 15m/min

|

|

Pressed shaft diameter

|

Φ70mm

|

|

Profile wheel

|

45# steel hard chrome plating

|

|

Equipment chassis

|

300H

|

|

Number of forming rows

|

840/11

|

|

Platen thickness

|

0.3-0.6mm

|

|

Hydraulic shearing machine power

|

3kw

|

|

Voltage

|

380V/220V

|

|

Dimension

|

5500*1400*1500mm

|

|

Weight

|

2500kgs

|

Customer Photos

Packing & Delivery

Details Images

Hot Searches