- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

About 4000*1650*1850mm

-

Weight:

-

3600 KG, 3600kg

-

After-sales Service Provided 1:

-

Engineers available to service machinery overseas

-

After-sales Service Provided 2:

-

Field maintenance and repair service

-

Color:

-

Blue or customized

-

Name:

-

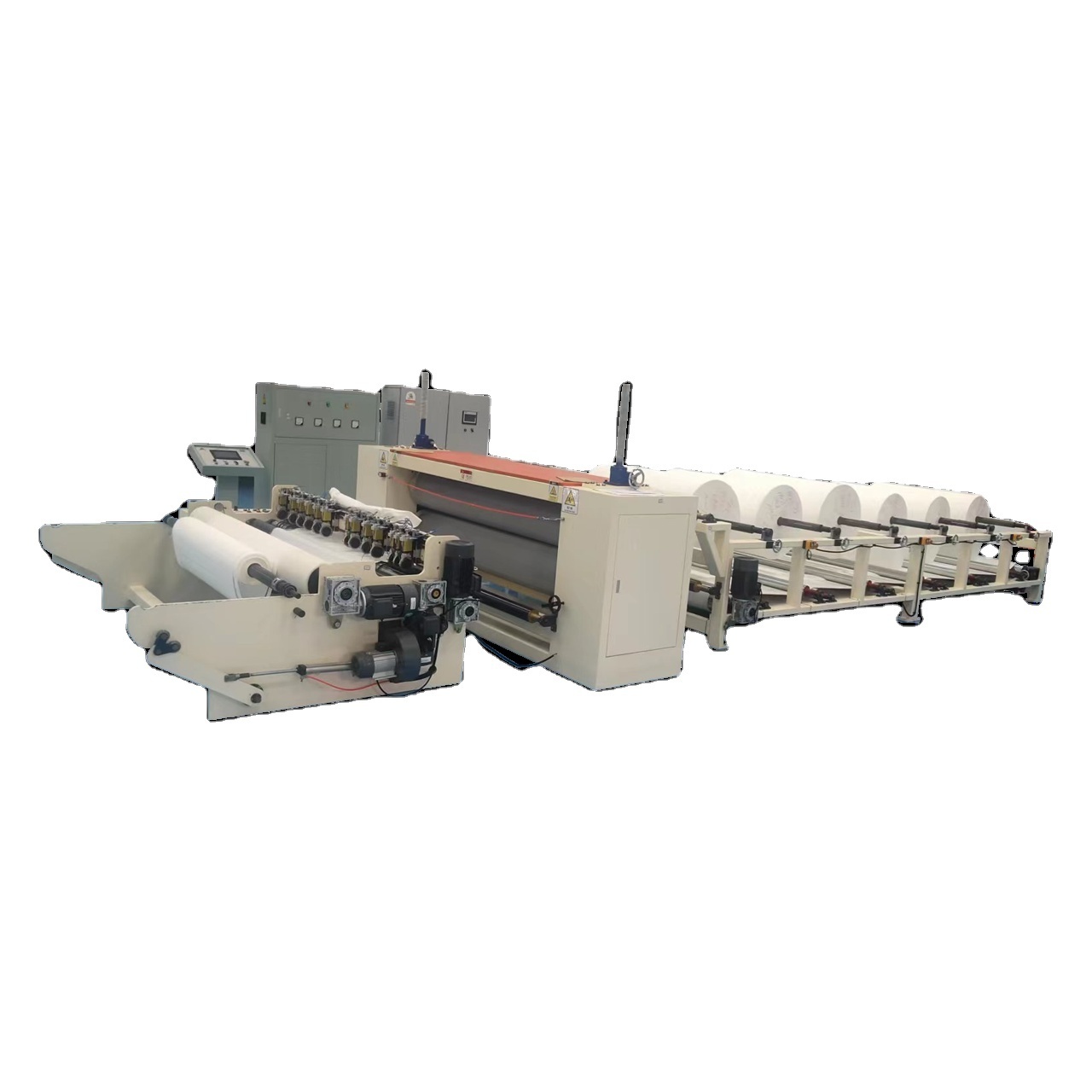

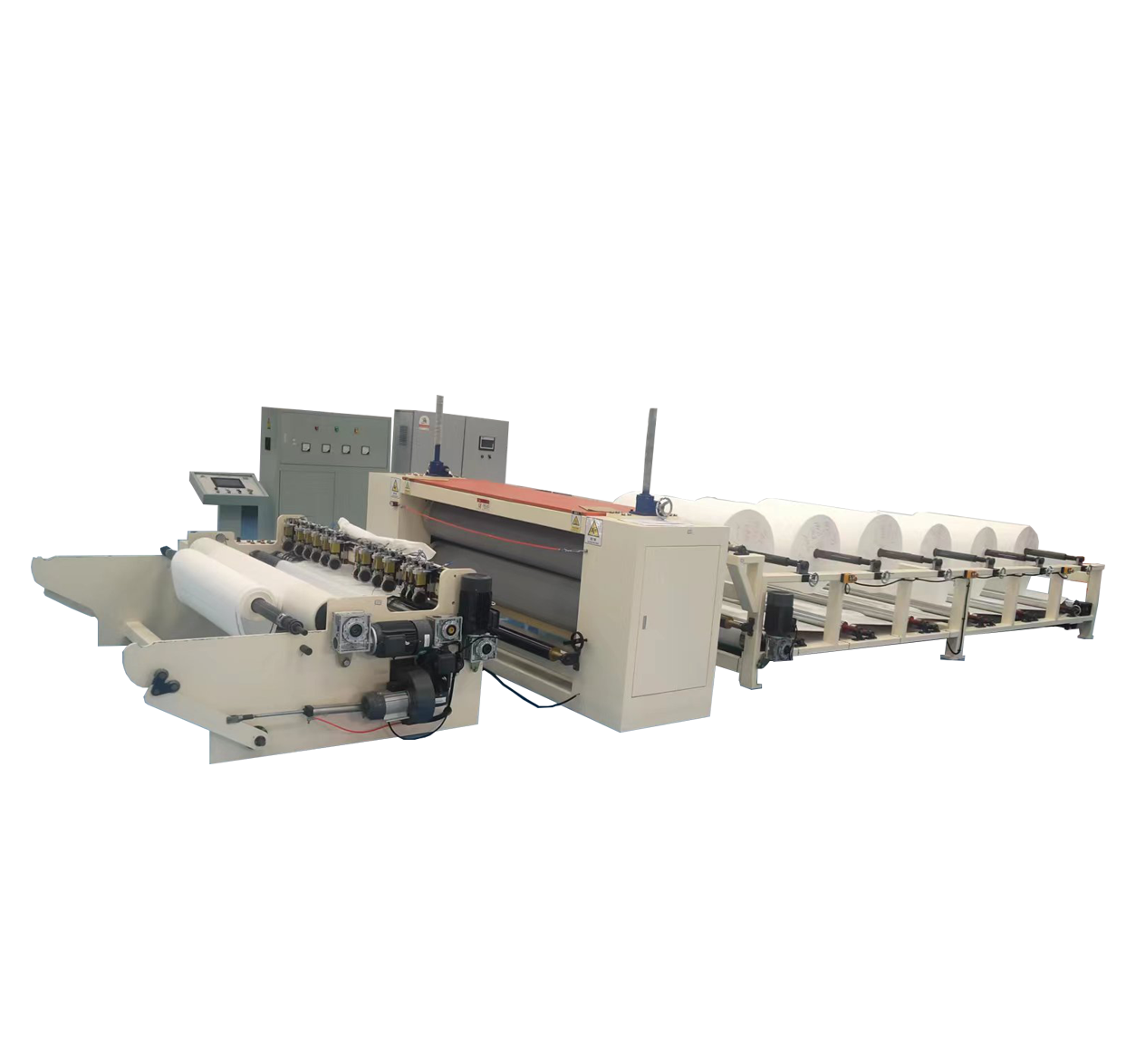

foam embossing machine

-

Certification:

-

ISO9001

-

name:

-

Factory supply foam embossing machine embossing fabric machine

-

POWER:

-

about 25kw

-

Usage:

-

Letters Press Embosser Machine

-

Local Service Location:

-

Uzbekistan

Quick Details

-

Voltage:

-

380V/50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xiehe

-

Dimension(L*W*H):

-

About 4000*1650*1850mm

-

Weight:

-

3600 KG, 3600kg

-

After-sales Service Provided 1:

-

Engineers available to service machinery overseas

-

After-sales Service Provided 2:

-

Field maintenance and repair service

-

Color:

-

Blue or customized

-

Name:

-

foam embossing machine

-

Certification:

-

ISO9001

-

name:

-

Factory supply foam embossing machine embossing fabric machine

-

POWER:

-

about 25kw

-

Usage:

-

Letters Press Embosser Machine

-

Local Service Location:

-

Uzbekistan

Machines that you may be interested ,please click below link :

1. Fabric/ Cloth /Sponge / Sandpaper Laminating Machine

2. Die Cutting machine /Punching machine/Cutter machine

3. Embossing/Quilting/Sewing machine/ultrasonic embossing machine

Factory supply foam embossing machine embossing fabric machine

|

Model

|

SH1-165a

|

|

Power Supply

|

380V50Hz

|

|

Effective Width

|

1000mm

|

|

Heating method

|

Electric heating

|

|

Compressed air

|

6mpa

|

|

Width of the roller

|

1200mm

|

|

Designed speed

|

5-1200m/h

|

|

Capacity power

|

25kw

|

|

Weight

|

about2000kg

|

Production Application:

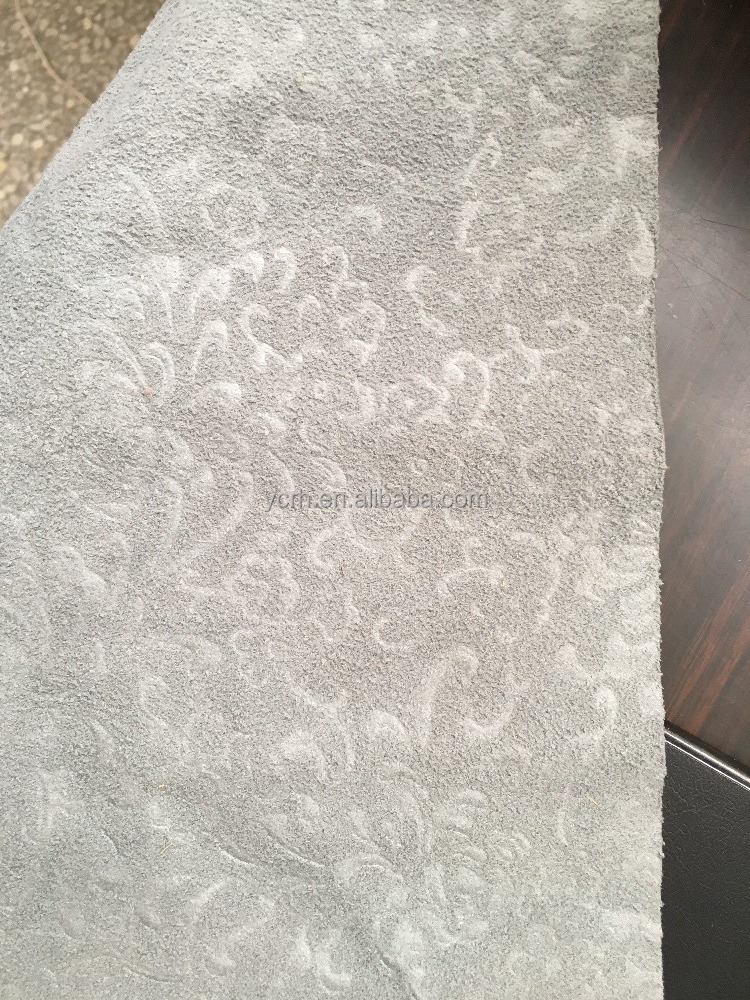

Used for decoration, shoes material, the papermaking, the leather, PU, PVC, leather, EVA flexible material embossing .

Equipment features:

1.When start working , push the heating button and set the temperature to let the temperature in an ideal working situation.

2.Turning on the main motor.Adjusting the production speed. Choose suitable heating temperature and speed according to material and pattern requirement .

3.The unwinding and winding device is used of tension control system to ensure the flat of the material .