- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

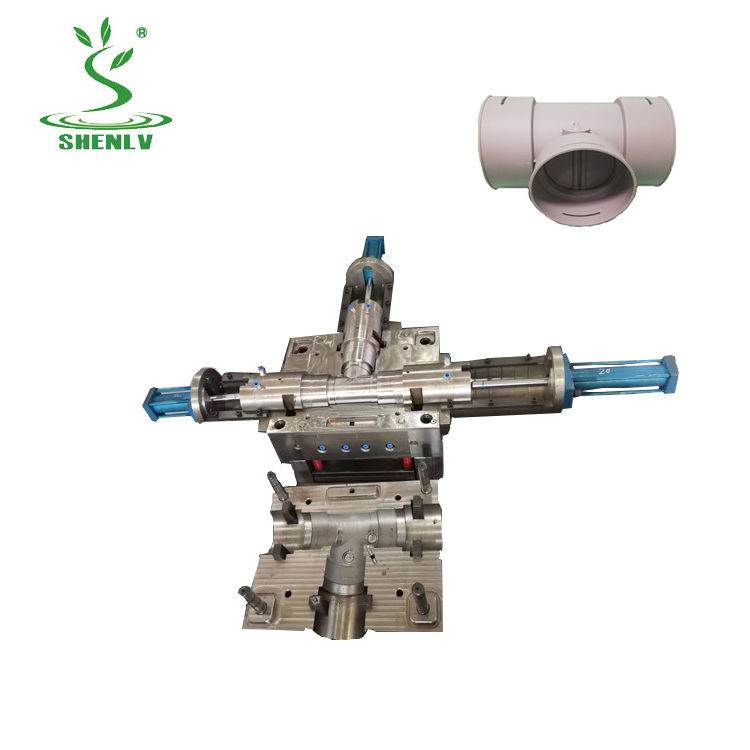

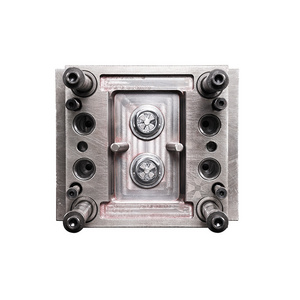

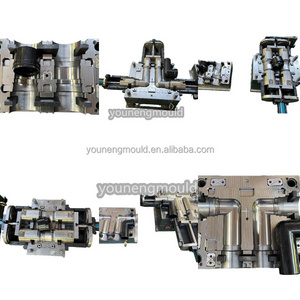

Pipe fitting mould

-

Main thechnology:

-

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes

-

Mould material:

-

45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.

-

Mould base:

-

LKM, HASCO ect

-

Cavity:

-

Single/multi

-

Runner:

-

Hot Runner\ Cold Runner

-

Design software:

-

UG, PROE, CAD, CAXA ect.

-

Plastic material:

-

PP, PC, PS, PE, PU, PVC, ABS, PMMA ect.

-

Mould life:

-

500,000-1,000,000 shots

-

We promise:

-

customer-centric, never for short-term profit, for long-term benefits

-

We produce:

-

Mold, prototype, injection molding, product assembly, surface printing

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

NO

-

Model Number:

-

Pipe fitting mould

-

Main thechnology:

-

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes

-

Mould material:

-

45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.

-

Mould base:

-

LKM, HASCO ect

-

Cavity:

-

Single/multi

-

Runner:

-

Hot Runner\ Cold Runner

-

Design software:

-

UG, PROE, CAD, CAXA ect.

-

Plastic material:

-

PP, PC, PS, PE, PU, PVC, ABS, PMMA ect.

-

Mould life:

-

500,000-1,000,000 shots

-

We promise:

-

customer-centric, never for short-term profit, for long-term benefits

-

We produce:

-

Mold, prototype, injection molding, product assembly, surface printing

Our Advantages

Products Description

|

Shaping Mode

|

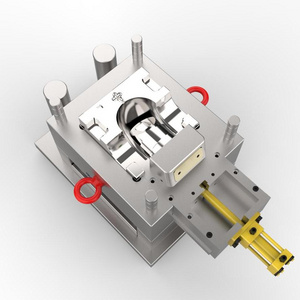

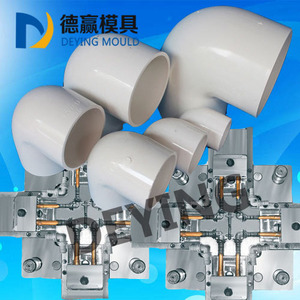

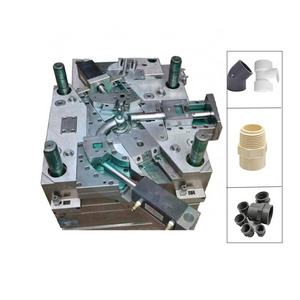

Plastic Injection Mould

|

|

Main Technique

|

Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc.

|

|

Mould material

|

45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.

|

|

Mould base

|

HASCO, DME, MISUMI, or by requested etc.

|

|

Cavity

|

Single/multi

|

|

Runner System

|

Hot runner, Cold runner

|

|

Design software

|

UG, PROE, CAD, CAXA ect.

|

|

Plastic material

|

PP, PC, PS, PE, PU, PVC, ABS, PA6,PMMA ect.

|

|

Mould life

|

300,000-3,000,000 shots

|

|

Specification

|

Depends on customer's requirements.

|

|

Delivery

|

Sea shipping, Air cargo

|

|

Lead time

|

25—45days for mould, plastic products according to quantity

|

|

1.Negotiation

|

The Quality, Price, Material, Delivery Time, Payment Item, Ect.

|

|

2.Place An Order

|

According Customers Drawings Or Samples, Or We Can Design For You.

|

|

3.R&d

|

According The Customer’s Requirement To Design Or Improve 3d Modle.

|

|

4.Drawing Confirm

|

According Customers Requirement To Design The Mould. Then We Send The Mould Design To Customers For Approval Befor We Make The

Mould |

|

5.Mould Processing

|

Cnc Machine Processing And Assembling .then Having The Mould Testing.

|

|

6.Sample Confirm

|

Before Shippment Or Move Forward To Production; We Send Samples To Customers To Confirm First.

|

|

7.Sample Shoot

|

If The First Sample Is Not Be Satisfied By Customers, We Modify The Mould Until Meet Customers Satisfaction.

|

|

8.Production

|

If Your Quantity Is Beyond Our Storage, We Will Provide Lead Time To You.

|

|

9.Delivery

|

Delivery The Goods By Sea Or Air ,follow The Customer’s Requirement

|

More Product

Packaging & Shipping

Hot Searches