- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1300 KG

-

Place of Origin:

-

China

-

Brand Name:

-

kenchi

-

Voltage:

-

220V/380V, 220V or 380V, 3 Phase

-

Dimension(L*W*H):

-

3400*2250*2450mm

-

Power (kW):

-

45 kW

-

Capacity:

-

200L(Customizable)

-

Weight:

-

3400*2250*2700mm (after rasing)

-

Power:

-

45Kw

-

OIl boiler:

-

80L

-

Water boiler:

-

120L

-

Heating method:

-

Electric heating or steam heating

-

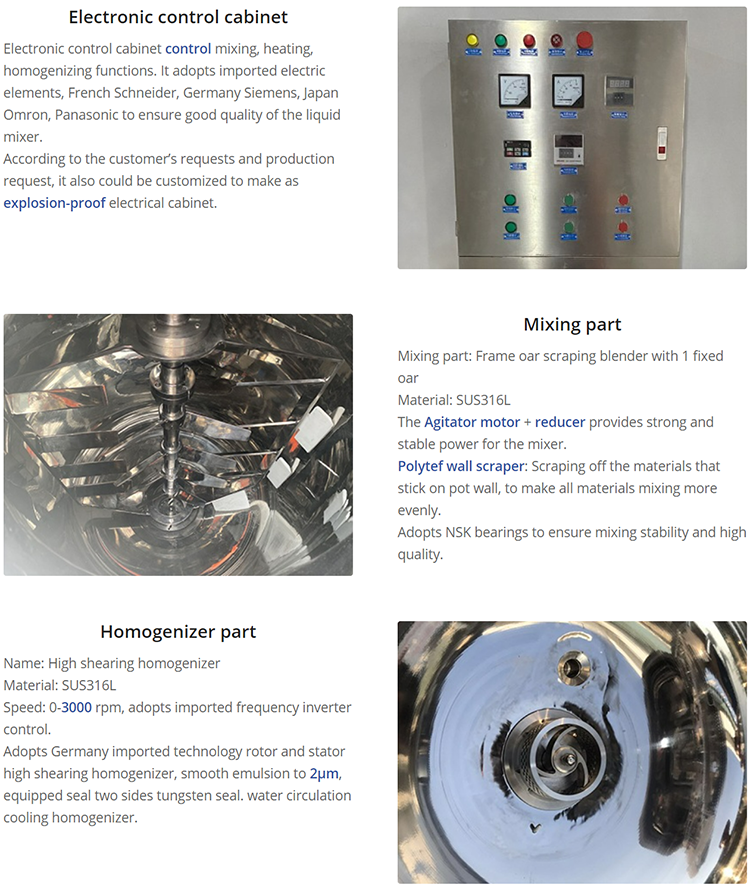

Control:

-

Electric Control Box

Quick Details

-

Barrel Volume (L):

-

200

-

Max. Loading Volume (L):

-

250 L

-

Max. Loading Capacity:

-

250

-

Weight (KG):

-

1300 KG

-

Place of Origin:

-

China

-

Brand Name:

-

kenchi

-

Voltage:

-

220V/380V, 220V or 380V, 3 Phase

-

Dimension(L*W*H):

-

3400*2250*2450mm

-

Power (kW):

-

45 kW

-

Capacity:

-

200L(Customizable)

-

Weight:

-

3400*2250*2700mm (after rasing)

-

Power:

-

45Kw

-

OIl boiler:

-

80L

-

Water boiler:

-

120L

-

Heating method:

-

Electric heating or steam heating

-

Control:

-

Electric Control Box

Product Detail

| Material | SUS 304 and 316 |

| Capacity | 200L(Customizable) |

| Mixer Type | homogenizing, emulsifying, heating |

| Weight | 3400*2250*2700mm (after rasing) |

| Voltage | 220V or 380V, 3 Phase |

| Power | 45Kw |

| OIl boiler | 80L |

| Water boiler | 120L |

| Heating method | Electric heating or steam heating |

| Control | Electric Control Box |

Description:

Vacuum emulsifying mixer machine consists of water and oil pot, Main emulsifying tank, vacuum system, tilting discharge system, hydraulic lifting system, mixing system, homogenizer system and heating/cooling system. It’s used to produce cream, lotion, paste, ointment, paste, conditioner, etc.

Key Features:

1. The emulsifying pot lid adopts a hydraulic lifting system, easy to clean, the emulsifying pot can adopt tilt discharge.

2. Vacuum defoaming can make the materials meet the requirement of being aseptic. The vacuum material sucking adopted can avoid dust.

3. PTFE scraping board cater to the body of blending groove and scrape out viscosity material on the boiler wall.

4. Homogenizer is installed on the boiler bottom to increase motor power more thoroughly and strongly. During a few productions, it can exert the homogenizing effect fully.

5. Mightiness balance isotactic curve rotor is matched with the stator to realize liquid high-capability cut, rubbing, centrifugal to make sure exquisite and slick cream.

6. Boiler body and pipe surface mirror polishing 300 mesh (sanitation grade) accord with Daily chemical and GMP regulation.

7. SIEMENS frequency converter for speed adjustment of 0-3000 rpm, which can meet the production of different technology requirements.

8. Burgmann mechanical sealing, good sealing effect, and long working life.

9. Material contact parts all use SUS316L stainless steel.

10. The heating method mainly includes electric or steam heating for the customer’s choice.

11. Advanced PLC touch screen control is optional .

Details:

WHY CHOOSE IT