- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 50HZ

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jinggang

-

Gross Power:

-

1600W

-

Dimensions(L*W*H):

-

650 * 650 * 900mm

-

Weight:

-

130 KG, 130Kg

-

feeding:

-

Motor Drive

-

Power:

-

220V 50HZ

-

stamping plate area:

-

290 * 210mm

-

table size:

-

400 * 320mm

-

maximum pressure:

-

4000kg

-

The up and down stroke:

-

40mm

-

heating power:

-

1600W

-

temperature range:

-

room temperature -300 ° C

-

Model of embossing machine:

-

TJ-30 manual embossing machine

Quick Details

-

Condition:

-

New

-

Plate Type:

-

Flatbed Printer

-

Color & Page:

-

single color

-

Voltage:

-

220V 50HZ

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jinggang

-

Gross Power:

-

1600W

-

Dimensions(L*W*H):

-

650 * 650 * 900mm

-

Weight:

-

130 KG, 130Kg

-

feeding:

-

Motor Drive

-

Power:

-

220V 50HZ

-

stamping plate area:

-

290 * 210mm

-

table size:

-

400 * 320mm

-

maximum pressure:

-

4000kg

-

The up and down stroke:

-

40mm

-

heating power:

-

1600W

-

temperature range:

-

room temperature -300 ° C

-

Model of embossing machine:

-

TJ-30 manual embossing machine

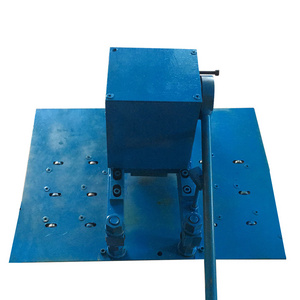

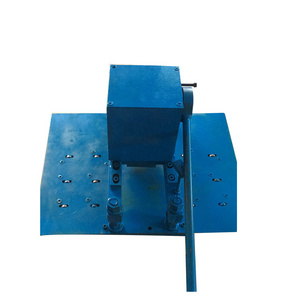

TJ-30 Manual Number Plate Press Machine / License Plate Manual Emboss Machine / Hand Manual License Plate Making Machine

1.Product parameters of embossing machine:

Quality / Safety Certification: ISO9001-2000 CE certification

2. Technical parameters of embossing machine :

|

Power |

stamping plate area |

table size |

maximum pressure |

The up and down stroke |

heating power |

temperature range |

Weight |

Dimensions |

|

220V 50HZ |

290 * 210mm |

400 * 320mm |

4000kg |

40mm |

1600W |

room temperature -300 ° C |

130Kg |

650 * 650 * 900mm |

3.Advantages of embossing machine:

(1).Electrical control, operation easy

(2). Workbench multi-faceted trim

(3). Pressure, temperature, speed adjustable

(4).Automatic document feeder, the collection of paper, and adjustable

(5). Workpiece mold with built-preheating device.

4.Product Description of embossing machine

This machine is suitable metal, plastic the workpiece circumference stamping and thermal transfer, or pressed paper cups, plastic PVC and other artifacts around stamping or thermal transfer

5. temperature reference of embossing machine

|

Paper |

PVC: |

soft soft plastic |

Hard plastic artificial leather |

Synthetic leather leather |

|

85-120 °C |

65-80 °C |

75-85 °C |

120-150 °C |

160-180 °C |

6. Matters needing attention duiring embossing process

(1). According to the different varieties of scalded object, select the appropriate hot stamping foil.Good sized

must master the temperature, pressure, stamping speed three party coordination, and according to the

short-run printing materials, area of difference.

(2).The cutting knife should grasp the direction and speed of car;

(3).The anodized hot stamping foil should choose attributes suitable paper, ink (especially black kerosene, composite glue, hot stamping parts must be kept dry, so as to avoid the bronzing layer oxidizing or injury;

(4). The general packaging: 0, 64 × 120m volumes, each volume 10: a box can be custom width of 0.64M, length of 240m or 360m rolls or other special specifications;

(5). When stored to prevent pressure, moisture, heat, sunscreen, placed in a cool ventilated place.

7.Product show of embossing machine

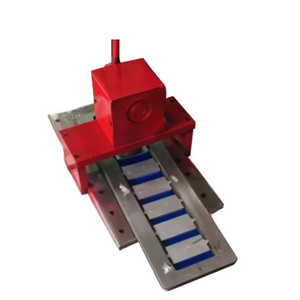

Work Process of embossing machine:

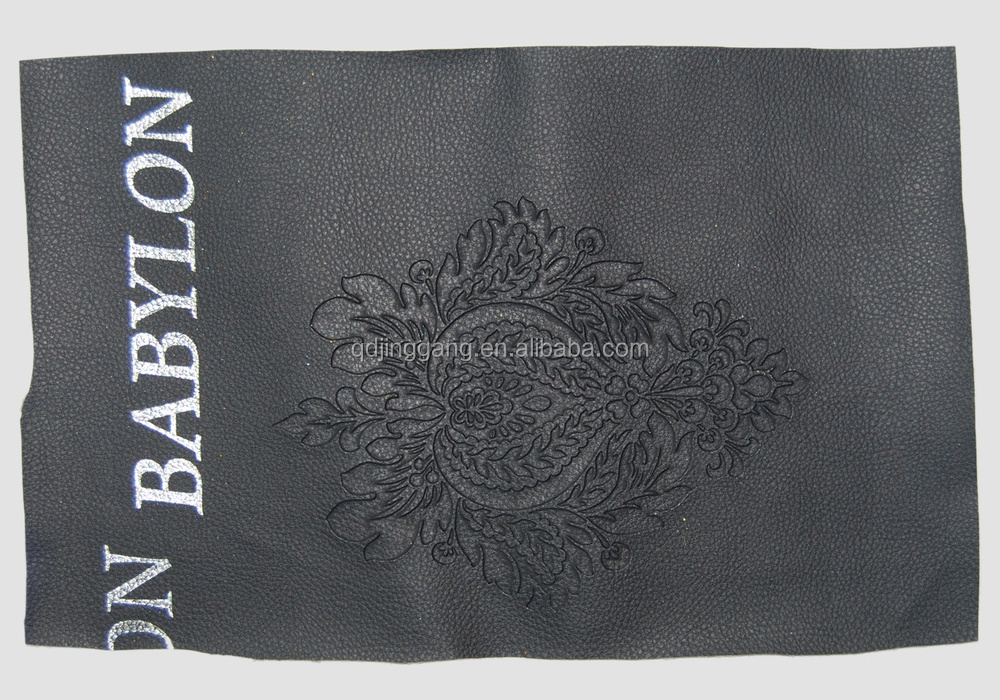

Samples made by embossing machine:

Note: We can cutomize embossing machines according to your requirements.

Packing and delivery of embossing machine (complete wood box packing avoid machine damage or parts missing):

Certifiaction of embossing machine:

The Reasons of Cooperation with Jinggang:

1). Jinggang is meeting what customer's need, manufacturing the advanced equipment.

2).Researching and developing in dependently , products are variety and practical.

3) .Paying more attention to service, using technology to solve difficult problems of customers.

4) .Producing and marketing products by oneself.

5) G uarantee time is 12 months. S pare parts will be prepared in the tool box together with machines.