- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

1%

-

CrO Content (%):

-

1%

-

SiC Content (%):

-

85%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

STA-SSC02

-

Brand Name:

-

STA

-

Hardness:

-

Mohs 9.5

-

Thermal conductivity at:

-

Btu/fthF @300oC 50

-

Flexural Strength:

-

PSI 70000

-

Max service temperature:

-

oC 1600

-

Compressive Strength:

-

PSI 500000

-

Linear Coe. Of thermal Expansion:

-

10-6/oC

-

Size:

-

Customized Size

-

Application:

-

Refractory Material

-

Product name:

-

Sintered Alpha sic tube/Silicon Carbide ring

Quick Details

-

SiO2 Content (%):

-

2%

-

Al2O3 Content (%):

-

5%

-

MgO Content (%):

-

1%

-

CaO Content (%):

-

1%

-

CrO Content (%):

-

1%

-

SiC Content (%):

-

85%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

STA-SSC02

-

Brand Name:

-

STA

-

Hardness:

-

Mohs 9.5

-

Thermal conductivity at:

-

Btu/fthF @300oC 50

-

Flexural Strength:

-

PSI 70000

-

Max service temperature:

-

oC 1600

-

Compressive Strength:

-

PSI 500000

-

Linear Coe. Of thermal Expansion:

-

10-6/oC

-

Size:

-

Customized Size

-

Application:

-

Refractory Material

-

Product name:

-

Sintered Alpha sic tube/Silicon Carbide ring

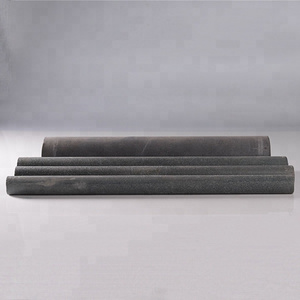

STA-Sintered Alpha sic tube/Silicon Carbide ring

STA offers Sintered Alpha Silicon Carbide Products. Alpha silicon carbide material is most commonly used in sintered products in industrial application. It is formed by mixing very fine silicon carbide powder with non-oxide sintering additives at sintering temperature between 2000oC to 2600oC under vacuum or inert atmosphere to form very dense products. Silicon carbide tube and parts can be formed by casting, dry press, extrusion, isostatic press and injection moulding. Various complicated shapes can be formed by these process technologies. Due to its very fine gain size and high density, sintered alpha silicon carbide product has excellent surface finishing and tight dimensional control that require non or minimum after-sintering.

- Available Tube Diameter From 3/4" to 9" for American size and 20 mm to 150 mm for metric unit.

- Available Tube Length: From 1" ( 25mm) To 72" ( 1828mm).

- Most items are in Stock and can be delivered in 1-3 days.

- SentroTech also offer volume discount for all listed sizes if order quantity is more than 5 pieces for same size.

- Please Specify the Tube ID, OD and Length In the Quote Request Form

Sintered Silicon Carbide Products offer very unique properties which include:

- High hardness next to diamond.

- Extremely wear and abrasion resistance.

- High flexural strength at room or high temperature.

- Excellent thermal shock resistance due to its low thermal expansion and high thermal conductivity.

- Excellent corrosion resistance.

- High temperature resistance.

Typical Application Of Sintered Silicon Carbide Products

- Wear and abrasion resistance tube and parts for power industry.

- Corrosion resistance parts for chemical and paper industries.

- Oil extraction parts in oil drilling industry.

- Automotive components, mechanical sealing and sealing ring.

- Heat exchange tubes.

- Structure materials and crucible for semiconductor industry.

| Sintered Silicon Carbide (SiC) Properties | ||

| Properties | Unit | Value |

| Color | Gray | |

| Hardness | Mohs | 9.5 |

| Density | g/cm 3 | 3 |

| Thermal conductivity at | Btu/fthF @300oC | 50 |

| Compressive Strength | PSI | 500,000 |

| Flexural Strength | PSI | 70,000 |

| Max service temperature | o C | 1600 |

| Linear Coe. Of thermal Expansion (25C-600C) | 10-6/ o C | 4 |

Q: Are you trading company or manufacturer ?

A: We are a manufacturer offer any customized service.

Q: How long is your delivery time?

A: Generally it is 3 working days if the goods are in stock. or it is 20-25 working days if there is no in stock

Q: Do you make the test before shipping ?

A: Yes, we will do the testing before packing.

Q: Can we visit your factory ?

A: Yes, welcome to come !