- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

3000

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

hongfa

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

4000*2000*2650mm

-

Weight:

-

13000 kg

-

Marketing Type:

-

Hot Product 2023

-

Usage:

-

Granite Marble Stone Processing

-

Applicable material:

-

Granite Tombstone Stone Edge Polishing

-

Description:

-

Marble Granite Auto

Quick Details

-

Type:

-

Stone Engraving Machine

-

Power:

-

30kw

-

Cutting thickness (max):

-

60mm

-

Production Capacity:

-

3000

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

hongfa

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

4000*2000*2650mm

-

Weight:

-

13000 kg

-

Marketing Type:

-

Hot Product 2023

-

Usage:

-

Granite Marble Stone Processing

-

Applicable material:

-

Granite Tombstone Stone Edge Polishing

-

Description:

-

Marble Granite Auto

|

|

|

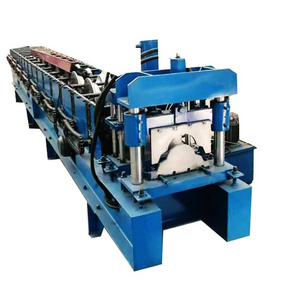

HFT650 All-in-one machine for curbstone and Terrazzo tile slab pressing color stone marble tile making machine Terrazzo tile polisher, HFT650 terrazzo tile slab making machine 1200*620 mm terrazzo floor tile press machine for sale cement tiles colored stone slab

Description of molding process

- HFT650 concrete slab making machine, the forming process adopted is a forming process used to form the concrete slurry by high pressure pressing. It is characterized in that during the pressing process, the water in the slurry can be squeezed out so that the green body can be quickly formed and demoulded, and in the process of squeezing out the water, the concrete slurry is locked so that it will not be lost together with the water. To preserve the strength of the finished product.

Advantages

The advantage of this process is that it can be pressed with wet concrete slurry, the finished product has less air holes, and has a relatively good degree of bonding between cement and sand; at the same time, it has a looser ratio in moisture control than dry hardness. (15%-20%, dry hardness 6%-8%); at the same time, no vibration is involved in the molding process, so the noise is relatively small during mechanical operation.

| Technical Parameters | |

|

Production capacity

|

700m2 /8hours |

|

Preset pressure

|

500 ton |

|

Forming method

|

Hydraulic press |

|

Switchboard power

|

30KW

|

|

Product specification

|

1000*200-500*100-200mm

|

|

Dimensions

|

4000*2000*2650mm

|

|

Host machine weight

|

13000KG |

|

Labor capacity

|

4-5 wokers/shift |

Mold Features

- The mold is a combined structure of mold core, frame, liner and socket, which is easy to repair and replace

- The main part of the mold is made of integral pouring material, and the mold has a long service life

- The upper head and the lower mold core are equipped with drainage holes and auxiliary drainage grooves, which are convenient for quickly filtering out water during the molding process

- The indenter and core are equipped with a detachable filter layer for filtering mud, which is easy to disassemble, wash and replace.

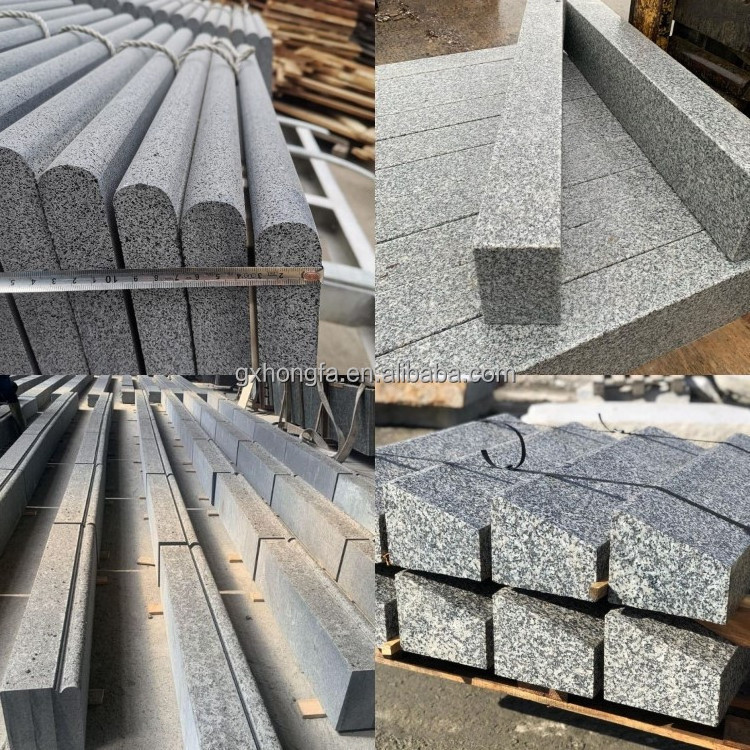

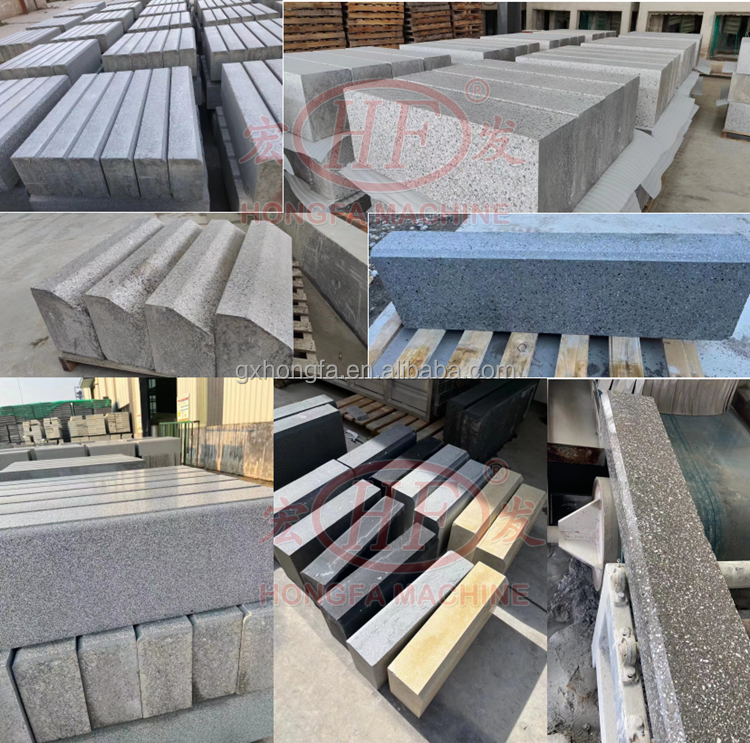

Finished products

Raw materials

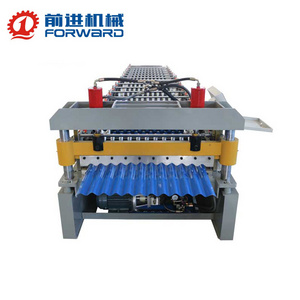

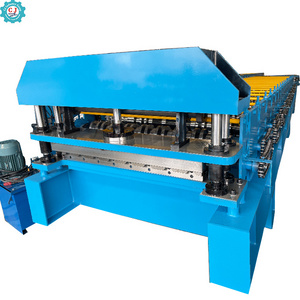

Polishing machine

Similar Products