- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

850*750*950mm

-

Weight:

-

2120 KG

-

Name:

-

Flotation Concentrator

-

Material:

-

Stainless steel

-

Application:

-

Copper, lead, nickel, cobalt, Mo, molybdenum, antimony

-

Color:

-

As your require

-

Installation:

-

Engineer Guide

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Production Capacity:

-

1.5-3.5 m3/min

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Jiangxi Hengchang Flotation Concentrator

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

850*750*950mm

-

Weight:

-

2120 KG

-

Name:

-

Flotation Concentrator

-

Material:

-

Stainless steel

-

Application:

-

Copper, lead, nickel, cobalt, Mo, molybdenum, antimony

-

Color:

-

As your require

-

Installation:

-

Engineer Guide

-

After-sales Service Provided:

-

Field installation, commissioning and training

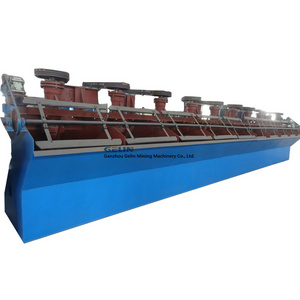

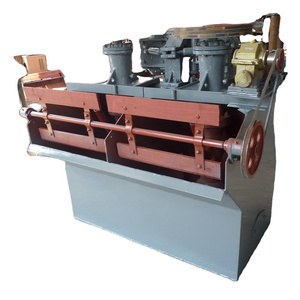

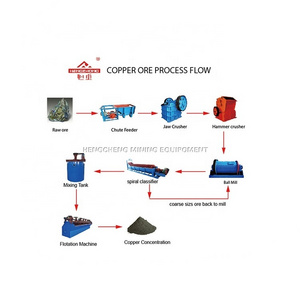

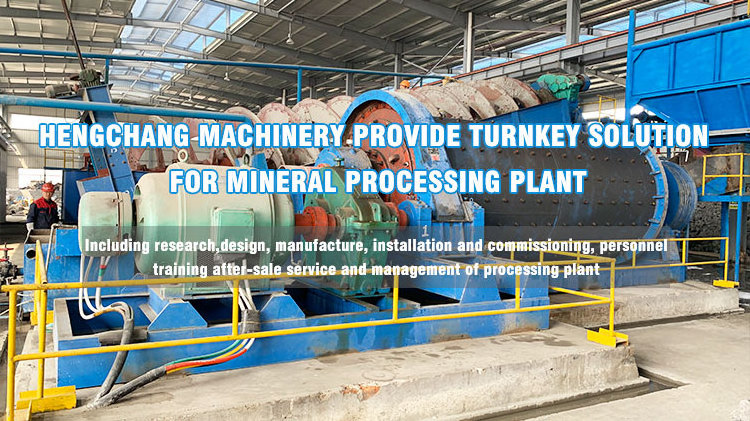

Zimbabwe Small Scale Rock Copper Ore Flotation Concentrator Processing Plant For Sale

Hengchang machinery

Flotation Concentrator

can be used for separating many minerals, such as gold, copper, tantalum, lead and zinc ore and so on. When you find us, you find a best mining machinery manufacturer.

Flotation Concentrator

Introduction:

Flotation Concentrator

can be used to separate non-ferrous metal, ferrous metal, noble metal, non-metallic mine, chemical material. It can be used in roughing,scavenging, selection or reverse flotation.In the flotation process, after being mixed with drug, some qualified mineral attaches on bubble, floats on the surface of slurry and is scraped out, other mineral still stays in the slurry.

Flotation Concentrator

Working Principle:

Flotation Concentrator

adopts creative forward tank,double side blades of water wheels, draft tube and the false bottom device. The slurry in tank takes upper and lower circulation according to the fixed flow mode, which is conducive to suspension of coarse particle.

Flotation Concentrator

Application:

Flotation Concentrator

can be used to separate non-ferrous metal, ferrous metal, noble metal, non-metallic mine, chemical material. It can be used in roughing,scavenging, selection or reverse flotation.In the flotation process, after being mixed with drug, some qualified mineral attaches on bubble, floats on the surface of slurry and is scraped out, other mineral still stays in the slurry, so the separating purpose is finished.

|

Category

|

Specification model

|

Effective cubage (m³)

|

Processing capcity (m³/min)

|

Main shaft loam board

|

|

|

|

|||

|

|

|

|

|

Power (kw)

|

Rotate speed (r/min)

|

Rotate speed (r/min)

|

Power (kw)

|

|||

|

XJK type

|

XJK-0.35

|

0.35

|

0.18-0.4

|

1.5

|

483

|

25

|

1.1

|

|||

|

|

XJK-0.62

|

0.62

|

0.3-0.9

|

3

|

400

|

25

|

1.1

|

|||

|

|

XJK-1.1

|

1.1

|

0.6-1.6

|

5.5

|

330

|

25

|

1.1

|

|||

|

|

XJK-2.8

|

2.8

|

1.5-3.5

|

11

|

280

|

25

|

1.1

|

|||

|

|

XJK-5.8

|

5.8

|

1.1-2.9

|

22

|

240

|

25

|

1.5

|

|||

|

SF type

|

SF-0.37

|

0.37

|

0.2-0.4

|

1.5

|

386

|

25

|

1.1

|

|||

|

|

SF-0.7

|

0.7

|

0.3-0.9

|

3

|

400

|

25

|

1.1

|

|||

|

|

SF-1.2

|

1.2

|

0.6-1.6

|

5.5

|

330

|

25

|

1.1

|

|||

|

|

SF-2.8

|

2.8

|

1.5-3.5

|

11

|

268

|

25

|

1.1

|

|||

|

|

SF-4

|

4

|

2.0-4

|

15

|

220

|

25

|

1.5

|

|||

|

|

SF-8

|

8

|

4.0-8

|

30

|

191

|

25

|

1.5

|

|||

|

|

SF-16

|

16

|

5.0-16

|

30

|

191

|

25

|

1.5

|

|||

|

|

SF-20

|

20

|

5.0-20

|

45

|

186

|

25

|

1.5

|

|||

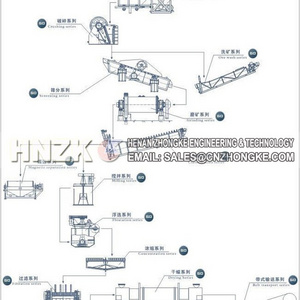

Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd. is located in No.3 Chuangye Road. Guzhang In dustrial Park. Shicheng County. Ganzhou City. Jiangxi Province. China. Our company is engaged in the mineral processing equipment research, development, design and product!on for many years history, has accumulated rich experience in design and production. Enterprise in mineral processing equipment industry has had a positive effect, set up the good reputa-

tion. And mainly the manufacture of the products like as Shaking table. Flotation equipment. Crushing equipment. Magnetic separator. Screening equipment. Classifying equipment. Agitation tank, Feeding equipment. Gravity separation equipment. Wet separation equipment. Spiral chute. Saw-tooth wave jig and Diaphragm Jig. Grinding equipment. Ball mill. Slurry pump. Centrifugal pump, Conveying equipment.

tion. And mainly the manufacture of the products like as Shaking table. Flotation equipment. Crushing equipment. Magnetic separator. Screening equipment. Classifying equipment. Agitation tank, Feeding equipment. Gravity separation equipment. Wet separation equipment. Spiral chute. Saw-tooth wave jig and Diaphragm Jig. Grinding equipment. Ball mill. Slurry pump. Centrifugal pump, Conveying equipment.

We manufacture various types of mineral processing machinery and equipment according to ourcustomers' requirements. Our products are widely used for sorting gold, silver, copper, iron, tungsten,lead. zinc. tin. molybdenum, nickel, tantalum, niobium, manganese ore, coal, monazite, rutile,diamonds, other precious metals and precious metals mine, and for the flotation colored, black metal, precious metals and other minerals. And we have export qualifications, our products sell well all over the world for several years, especially exported to Brazil. India. Indonesia.South Africa. Somalia, Philippines. Malaysia. Sudan, Nigeria. Russia, Ghana. Kazakhstan. Kyrgyzstan. Cambodia. Vietnam. Korea. Mongolia. Myanmar and other countries.

1. Pre-sale services:

(1) Select equipment model;

(2) Design and manufactLire products according to clients' special requirement;

(3) Train technical personnel for dients.

2.Services during the sale:

(1) Pre-check and accept products ahead of delivery;

(2) help clients to draft solving plans.

3. After-sale services:

(1) Assist dients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

(1) Select equipment model;

(2) Design and manufactLire products according to clients' special requirement;

(3) Train technical personnel for dients.

2.Services during the sale:

(1) Pre-check and accept products ahead of delivery;

(2) help clients to draft solving plans.

3. After-sale services:

(1) Assist dients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

Hot Searches