- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

900*900*780mm

-

Weight:

-

270 KG

-

Name:

-

ultrasonic vibrating screen chemical vibration mechanical sieve

-

Keyword:

-

ultrasonic vibrating screen

-

Valid diameter:

-

750mm

-

Precision:

-

Less Than 600 Mesh

-

Color:

-

Blue or As Required

-

Noise Level:

-

Below 75 dB

-

Cleaning system:

-

Ultrasonic System

-

Surface treatment:

-

Mirror Polishing

-

Feature:

-

High Screening Efficiency

-

Layer(s):

-

1-4 Layers

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DY

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

900*900*780mm

-

Weight:

-

270 KG

-

Name:

-

ultrasonic vibrating screen chemical vibration mechanical sieve

-

Keyword:

-

ultrasonic vibrating screen

-

Valid diameter:

-

750mm

-

Precision:

-

Less Than 600 Mesh

-

Color:

-

Blue or As Required

-

Noise Level:

-

Below 75 dB

-

Cleaning system:

-

Ultrasonic System

-

Surface treatment:

-

Mirror Polishing

-

Feature:

-

High Screening Efficiency

-

Layer(s):

-

1-4 Layers

U

ltrasonic vibrating screen price standard chemical vibration mechanical sieve

Product Display

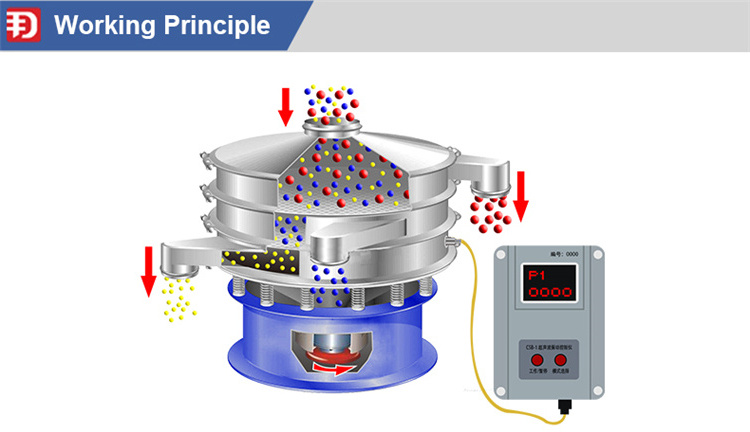

Product Introduction of Ultrasonic Vibrating Screen

The ultrasonic round rotary vibrating screen is consisit of the ultrasonic generator, transducer, resonant ring, vibration motor, screen body. The ultrasonic generator creates high frequency oscillation, and transducer will convert it to the high frequency sine shaped longitudinal oscillatory wave, then the oscillatory will be transmissed to the resonant ring and creates the sympathetic vibration, and the resonant ring will transmissed the vibration to the screen surface evenly. In this case, based on

the low frequency three dimensionl movement and supersonic vibration wave, the machine can not only keep off the screen mesh jam but also can improve the sieving capacity and quality.

Product Parameters

|

Model

|

Power (kw)

|

Valid Diameter (mm)

|

Layer (s)

|

|

DYC-600

|

0.55

|

550

|

1-3 layers

|

|

DYC-800

|

0.75

|

750

|

|

|

DYC-1000

|

1.1

|

950

|

|

|

DYC-1200

|

1.5

|

1150

|

|

|

DYC-1500

|

2.2

|

1450

|

|

|

DYC-1800

|

3

|

1750

|

|

Customer Case

Product Description

Advantages

1.Small size, light weight, saving space.

2.The direction of the discharge port can be adjusted, coarse and fine material automatically discharged.

3.No mesh plug, no powder flying, the smallest screen can be up to 500 mesh (28 microns), the smallest filter up to 5 microns.

4.Single layer rotary vibration screen with unique grid design, long-term use of screen, easy to change screen mesh, only 3-5 minutes, simple operation, easy to clean.

5.No mechanical action, easy maintenance, can be single or multi-layer, contact part of the material is made of stainless steel (except for medical use).

6.Any solid, liquid, powder, granules, slurry materials within a certain range can be screened.

Using Scope

1. Food industry

Our circular vibrating screen can be used for processing starch powder, sugar powder, sale, rice flour, milk powder, soybean mile, sauce, fruit juice, condiment, and so on.

2. Chemical industry

This rotary vibrating sieve is widely used for handling resin powder, paint, industrial chemicals, detergent powder, cosmetic, Chinese medicine powder.

3. Metallurgy industry

In metal processing industry, this rotary vibrating screen can sift aluminum powder, lead powder, copper powder, alloy metal powder.

4. Pollution abatement

Our circular vibrating screen is also suitable for treating waste oil, sewage, accessory ingredient, activated carbon.

Recommend Products

Hot Searches