10. Built in simple oscilloscope: you can view real-time capacitance, dynamic error and calibration curve;

11. Support advanced functions such as edge searching and frog jumping;

12. Support fixed height cutting function.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

CNC laser cutting controller

-

Axis:

-

6 axis

-

Maximum pulse frequency:

-

10 MHz

-

Control accuracy:

-

± 0.001 mm

-

Maximum running speed:

-

80 m/min

-

System working power supply:

-

DC+24V DC power input

-

Time resolution:

-

1ms"

-

Packing:

-

Carton size

-

Function:

-

Cutting

-

MOQ:

-

1 Piece

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Fangling

-

Weight(KG):

-

4

-

Product name:

-

CNC laser cutting controller

-

Axis:

-

6 axis

-

Maximum pulse frequency:

-

10 MHz

-

Control accuracy:

-

± 0.001 mm

-

Maximum running speed:

-

80 m/min

-

System working power supply:

-

DC+24V DC power input

-

Time resolution:

-

1ms"

-

Packing:

-

Carton size

-

Function:

-

Cutting

-

MOQ:

-

1 Piece

Product Description

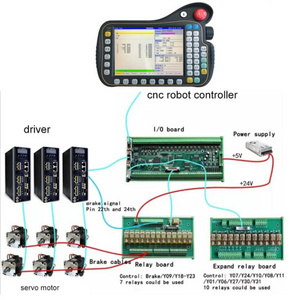

The L8000 series laser cutting CNC system is a digital control system for cutting machines based on in-dustrial control computers and modular platforms. This product absorbs the advantages of many lasercontrollers at home and abroad, combines our company's years of experience in the field of plasmaflame cutting, adopts muti axis digital control mode, introduces machine tool S-type acceleration/de-celeration interpolation technology, Bezier curve fitting algorithm, has lnternet/online control/remoteafter-sales and other functions. and is a CNC svstem suitable for laser cutting machines, makina cut-ting more efficient, high-quality, intelligent and convenient.

L8200W-SE: iMC6610 motion controller*1, iHC100B laser THC*1

PRODUCE FUNCTION

1. Built in nesting function, supporting graphic preprocessing.

2. Support one click common edge and common edge over-cutting.

3. Support layered cutting and layered process settings.

4. Support custom PLC processes.

5. Using S-type acceleration and deceleration and Béziercurve fitting algorithm, the machine tool runs more smoothly.

6. Support power off memory protection.

7. Support pulse type and analog quantity automatic focus axis control.

8. Support exchange workbench control.

9. Support flight cutting.

10. Support automatic edge correction.

11. Support edge detection and one click cutoff。

12. Support fixed height cutting and outside the board follows.

13. THC supports one click calibration (easy to operate).

14. THC supports analog servo motor control for faster response.

15. Support expand the automatic feeding function of roll material.

16. Visual cutting file management module.

|

Motor Control Signal

|

Number of Control Axes

|

6 Axes

|

|

|

|

Maximum Pulse Frequency

|

>10MHz

|

|

|

|

Control Accuracy

|

± 0.001 mm

|

|

|

|

Maximum Running Speed

|

80 m/min

|

|

|

|

Working Power Supply of the System

|

DC+24V DC Power Input, Power Greater than 80W

|

|

|

|

Time Resolution

|

1ms“

|

|

|

|

Motion Control Performance

|

S-type Acceleration and Deceleration

|

|

|

Laser Control Signal

|

1-channel PWM Pulse Width Modulation Signal

4-channel 0-10V Analog Quantity DA Signal

|

|

|

|

I/O Signal

|

|

32-channel Photoelectric Isolation Output, Maximum Output Current 500mA

32-channel Photoelectric Isolation Input, Maximum Input

Current 50mA |

|

|

Work Environment

|

|

Temperature: - 10 ℃ to 70 ℃; Relative humidity 0-95% without condensation

|

|

|

Power Requirements

|

|

DC+24V DC Power Input, Power Greater than 80W

|

|

Torch Height Controller iHC100B

Not touch screen

* Back interface: Power Interface * 1, USB2.0 * 1, DB25 male interface * 1, DB9 232 male serial port * 1, RJ45 network interface, 4-pin aviation plug male

* 5-inch 800 * 480 high-resolution true color screen;

* High performance ARM-M4 series processor;

* The super large scale programmable device FPGA is used for signal sampling, which is fast and accurate;

* Keyboard with protective film, waterproof and dustproof;

* Chassis: all metal structure is completely shielded, which can prevent electromagnetic radiation, interference and static electricity.

Function:

1. Multi task real-time operating system, responding to user's operation in real time;

2. Graphical display interface, simple operation;

3. After modifying parameters or before performing some irreversible operations, a message prompt box will pop up to prevent misoperation;

4. Support 100M Ethernet RJ45 CNC system communication;

5. Support Ethernet online upgrade and USB flash disk firmware upgrade;

6. Support diagnostic testing of all IO, keys and servo motors for troubleshooting;

7. The NO and NC types of all input ports can be customized;

8. Support automatic reset after startup;

9. Alarm records: servo alarm, plate collision alarm, limit alarm, capacitor abnormal alarm, etc., up to 128 records, which can be viewed and cleared at any time;

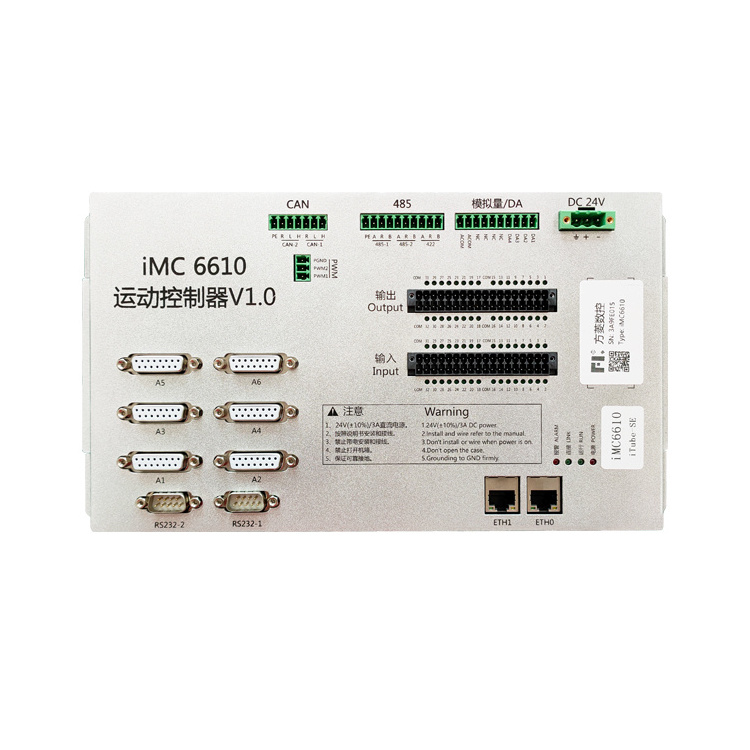

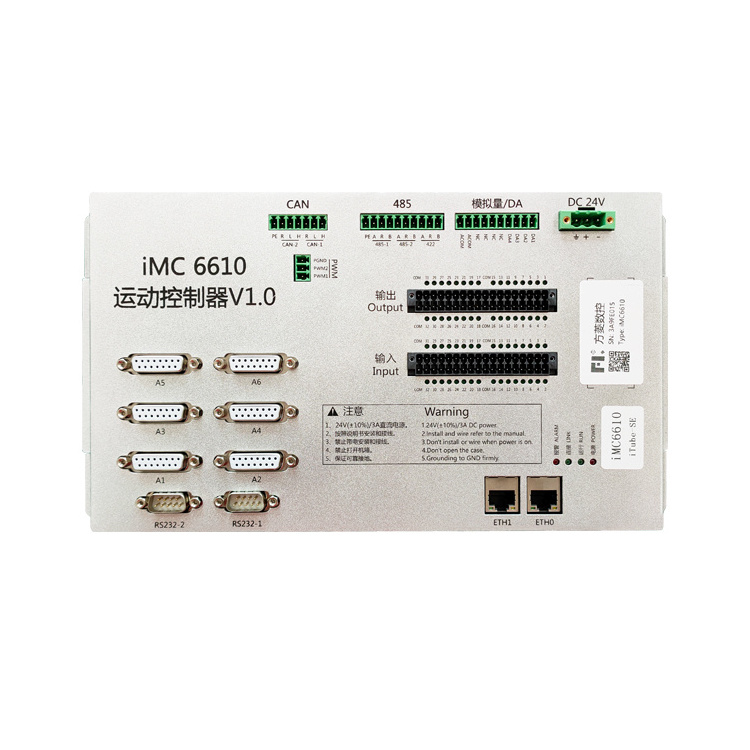

iMC6610 motion controller

1. Six motor axis outputs (X, Y, B1, B2 and focus axis can be configured arbitrarily) 2. Pulse output frequency: 3MHZ3. Motor

control mode: position control

4. Support encoder position detection

5. 4 channels 0 ~10V analog output

6. Support power off memory protection

7. 1 PWM output, 20 digital inputs, 32digital outputs 8. Network communication with industrial control host and THC

control mode: position control

4. Support encoder position detection

5. 4 channels 0 ~10V analog output

6. Support power off memory protection

7. 1 PWM output, 20 digital inputs, 32digital outputs 8. Network communication with industrial control host and THC

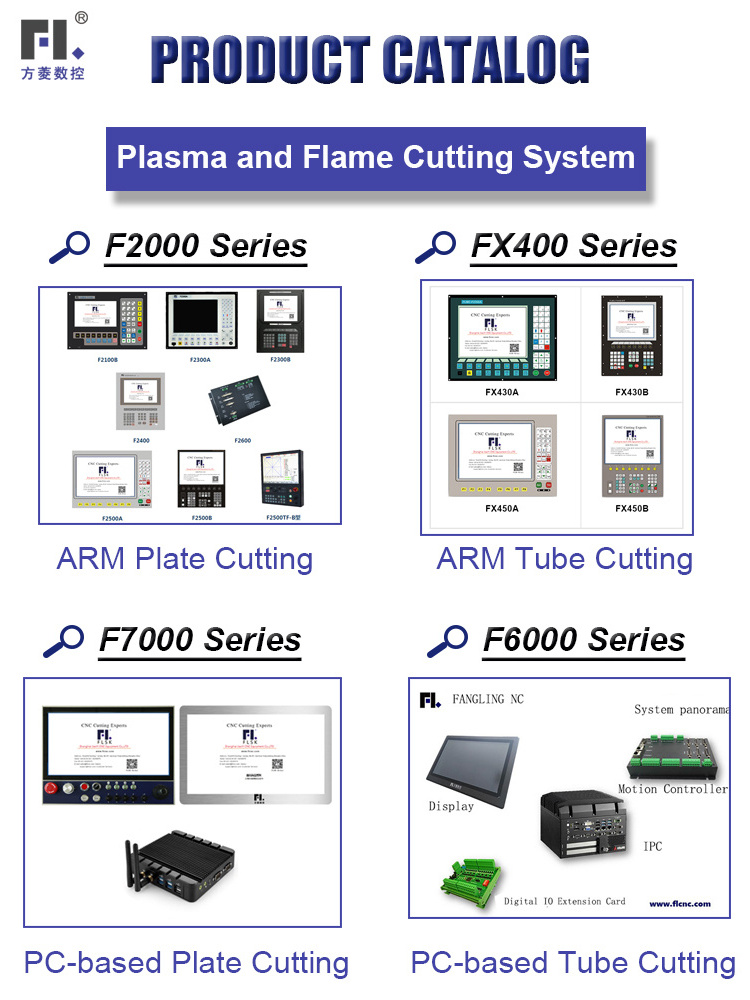

Catalog

Certifications

Hot Searches